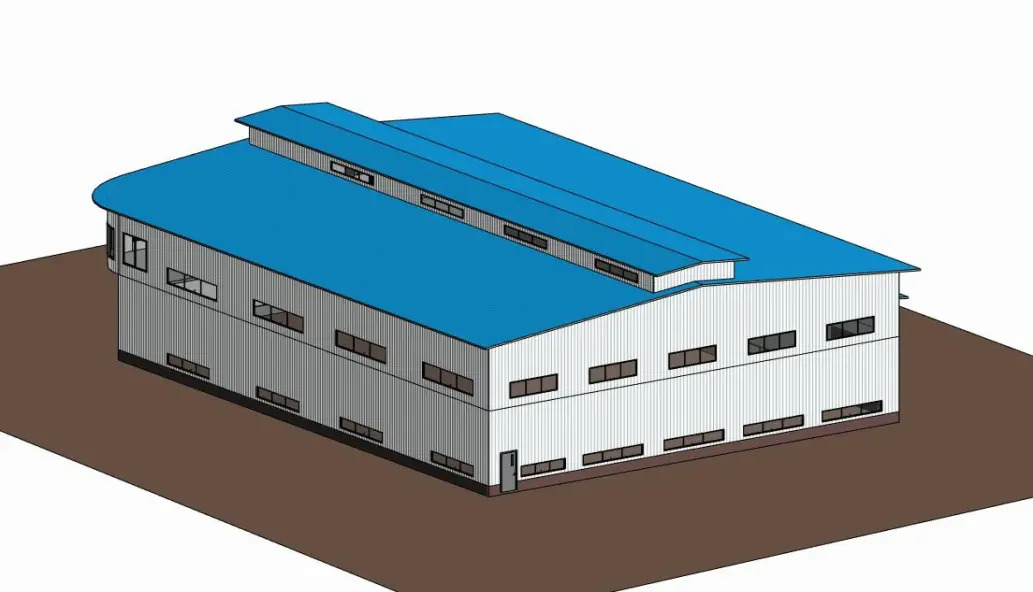

steel structure warehouse

group nameSteel Structure Buildings

-

Min Order500 square meter

brand nameZYM steel structure building Manufacturer

modelZYM1

payment methodL/C, D/A, Western Union, T/T

-

update timeThu, 28 Dec 2023 04:21:44 GMT

Paramtents

Name Indonesia steel structure warehouse workshop

Key word Indonesia steel structure workshop with office

Design 3D max,CAD for steel structure frame

Material Q235,Q345B,SS400 steel structure

Foof Galvanized color sheet or sandwich panel

Wall Galvanized sheet for steel structure workshop

Place of project Indonesia steel structure workshop and warehouse

Delivery time 30 days after steel structure drawing confirmation

Package Steel structure frame pallet for 40HQ container

Application workshop,warehouse,office,commercial bulding,shop

Packging & Delivery

Min Order500 square meter

Briefing

Detailed

ZhengYuanming Construction Engineering Co., Ltd.is specialized in prefab light steel structure warehouse,steel structure school building,steel structure shed,single span steel structure warehouse,PrefabricatedSteel Structure Workshop,steel structure high rise building,steel structure prefabricated workshop,Steel Structure Warehouse Workshop Shed,galvanized painted workshop,etc.we have 5 steel structure production lines. ZYM covers an area of more than 50,000 square meters, with excellent equipment, numerical control technology and high degree of automation. Our products are approved by PHI,TUV,BV,CE etc.All of our products comply with international quality standards and clients come from a variety of different markets throughout the world.such as Faroe Islands etc .Our goal is to offer the most safty and sercurity steel structure with more than 80 years life.High standard quaity and the most competitive price. By cooperation with us, you will have no worries behind. Our design will be made by professional engineers and pass the design code,our material will be purchased from top ten steel material company, our fabrication will be done by the most skilled workers .Stable steel structure, build your future.

| Product name |

steel structure warehouse |

|---|---|

| Brand Name |

ZYM |

| Model Number |

STEEL - 01 |

| Material |

Composite board,Steel etc |

| Brand |

ZYM steel structure warehouse Manufacturer |

| Tolerance |

±1% |

| Keyword |

Metal sheet new steel structure warehouse,warehouse prefabricated,Metal Sheet Steel Structure Warehouse,prefab Bar Storage steel structure Warehouse,house steel structure workshop Top Selling |

| Material |

Q235,Q345B,SS400 steel structure |

| Delivery time |

30 days after steel structure drawing confirmation |

| Certificate |

PHI,TUV,BV,CE etc. |

| Package |

Steel structure frame pallet for 40HQ container |

| Application |

gable frame steel structure warehouse,small size steel structure warehouse,steel structure architecture,prefab high-strength steel structure warehouse,single story steel structure warehouse |

| Processing Service |

Bending, Welding, Decoiling, Cutting, Punching |

| FOB port |

Qingdao Guangdong Shanghai |

| Terms of Payment |

L/C, D/A, Western Union, T/T |

| FOB port |

Qingdao Guangdong Shanghai |

| Processing Service |

Bending, Welding, Cutting, Punching, Pre-assembling, Painting |

| Project Solution Capability |

graphic design, 3D model design, total solution for projects |

| Main Materials |

light steel construction |

| Color |

Request, colorful |

| Design Style |

Modern |

| Characteristics |

Safe foundation, anti-seismic and windproof |

| Sales country |

Albania,Brunei,Norfolk Island,Northern Mariana Islands,Libya,Finland |

steel structure warehouse For further information feel free to contact us

Dead load is 0.3 kN Live load is 0.5 kN Wind load is 0.4 kN

We always do free steel structure warehouse building design for clients with CAD and 3D max.steel structure warehousesteel structure warehouse services FAQs GuideAre you looking for a quick review guide about steel structure warehouseservices?An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding steel structure warehouse services.Let’s continue!

2.How does the weight of a steel structure building affect site preparation and construction?

3.What is the seismic resilience of steel structure warehouse?

4.Whats the quality assurance you provided and how do you control quality ?

5.steel structure warehouse What factors contribute to the strength and stability of a steel structure building?

6.What is the typical cost of maintenance for a steel structure building?

7.What safety precautions should be taken when working on a steel structure building?

8.How does the structural integrity of a steel structure warehouse improve safety?

9.Can steel structure warehouse be designed to be eco-friendly?

10.How do the construction time and labor costs for steel structure warehouse compare to traditional building methods?

11.What kind of company you are?

1.What is the process for constructing a steel structure building?

We focus on innovation and continuous improvement to maintain a competitive advantage. 1. Design: The first step in constructing a steel structure building is to design the building. This includes determining the size, shape, and layout of the building, as well as the type of steel to be used. 2. Fabrication: Once the design is complete, the steel components must be fabricated. This includes cutting, bending, and welding the steel into the desired shapes and sizes. 3. Erection: Once the steel components are fabricated, they must be erected on the building site. This includes assembling the steel components and connecting them to the foundation. 4. Finishing: The final step in constructing a steel structure building is to finish the building. This includes adding insulation, drywall, and other finishing touches.

2.How does the weight of a steel structure building affect site preparation and construction?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of steel structure warehouse products. The weight of a steel structure building affects site preparation and construction in several ways. First, the weight of the steel structure must be taken into account when designing the foundation and other structural elements. The foundation must be designed to support the weight of the steel structure, and the soil must be able to bear the load. Additionally, the weight of the steel structure must be taken into account when designing the crane and other lifting equipment used to move the steel structure into place. Finally, the weight of the steel structure must be taken into account when designing the temporary bracing and other support systems used during construction.

3.What is the seismic resilience of steel structure warehouse?

We maintain a stable growth through reasonable capital operations, focus on industry development trends and cutting -edge technologies, and focus on product quality and safety performance. Steel structure buildings are highly resilient to seismic activity due to their ability to absorb and dissipate energy. Steel structures are able to flex and bend during an earthquake, allowing them to absorb the energy of the seismic waves and reduce the amount of damage that occurs. Steel structures also have a high strength-to-weight ratio, meaning they can withstand large amounts of force without becoming too heavy or bulky. Additionally, steel structures are often designed with seismic bracing and other features to further increase their seismic resilience.

4.Whats the quality assurance you provided and how do you control quality ?

Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials,validated or tested materials, finished goods, etc.

5.steel structure warehouse What factors contribute to the strength and stability of a steel structure building?

We have broad development space in domestic and foreign markets. steel structure warehouse have great advantages in terms of price, quality, and delivery date. 1. Design: The design of a steel structure building is critical to its strength and stability. The design should take into account the loads that the building will be subjected to, such as wind, snow, and seismic forces. 2. Connections: The connections between the steel members are also important for the strength and stability of the building. The connections should be designed to be strong and secure, and should be able to resist the forces that the building will be subjected to. 3. Materials: The materials used in the construction of the steel structure building should be of high quality and should be able to withstand the loads that the building will be subjected to. 4. Foundation: The foundation of the building should be designed to be strong and stable, and should be able to support the weight of the building. 5. Maintenance: Regular maintenance of the steel structure building is important to ensure its strength and stability. This includes inspecting the building for any signs of corrosion or damage, and making any necessary repairs.

6.What is the typical cost of maintenance for a steel structure building?

We pay attention to the transformation of intellectual property protection and innovation achievements. Your OEM or ODM order design we have a complete confidentiality system. The cost of maintenance for a steel structure building can vary greatly depending on the size and complexity of the building. Generally, the cost of maintenance for a steel structure building is between 1-2% of the total cost of the building. This cost includes regular inspections, painting, and repairs.

7.What safety precautions should be taken when working on a steel structure building?

We have established a good reputation and reliable partnerships within the steel structure warehouse industry. 1. Wear appropriate safety gear, such as hard hats, safety glasses, and steel-toed boots. 2. Use appropriate fall protection equipment, such as safety harnesses and lanyards. 3. Use appropriate tools for the job, such as wrenches, hammers, and saws. 4. Secure all tools and materials to prevent them from falling. 5. Follow all safety protocols and procedures. 6. Inspect the structure for any signs of damage or wear before beginning work. 7. Be aware of your surroundings and watch out for any potential hazards. 8. Use appropriate lifting techniques to prevent injury. 9. Use appropriate scaffolding and ladders to reach higher areas. 10. Disconnect all power sources before beginning work.

8.How does the structural integrity of a steel structure warehouse improve safety?

We are a new steel structure warehouse manufacturer. The structural integrity of a steel structure building improves safety by providing a strong and stable framework that can withstand the forces of nature, such as wind, snow, and earthquakes. Steel is a strong and durable material that is resistant to corrosion and can be designed to meet specific structural requirements. Steel structures are also fire-resistant, which helps to protect occupants in the event of a fire. Additionally, steel structures are often designed with redundancy, meaning that if one part of the structure fails, the other parts can still support the building. This helps to ensure that the building remains standing and safe for occupants.

9.Can steel structure warehouse be designed to be eco-friendly?

We have a professional team that is committed to the innovation and development of steel structure warehouse. Yes, steel structure buildings can be designed to be eco-friendly. Steel is a highly recyclable material, so it can be reused in the construction of new buildings. Additionally, steel is a very strong material, so it can be used to create buildings that are more energy efficient and require less energy to heat and cool. Steel can also be insulated with materials such as recycled denim or other sustainable materials to further reduce energy consumption.

10.How do the construction time and labor costs for steel structure warehouse compare to traditional building methods?

Our steel structure warehouse products undergo strict quality control to ensure customer satisfaction. Steel structure buildings typically require less time and labor costs than traditional building methods. Steel structures are typically pre-engineered and pre-fabricated, meaning that much of the work is done off-site in a factory setting. This reduces the amount of time and labor needed on-site, as well as the amount of waste generated. Additionally, steel structures are often easier to assemble than traditional building methods, which can further reduce labor costs.

11.What kind of company you are?

ZYM Team Group focus on creating and protecting value. We offer the full range of steel structure products, from steel material to highly engineered building systems, as well as accessories. Our full production line offers high-quality products at competitive prices. We pay attention to every little detail to ensure our steel structure more perfect. ZYM has three modern base centers, one center is responsible for design and R&D, one center handles production ,one center is for the sales and service.The group maintains production facilities for high-quality prefabricated steel,steel structure with an annual output of 50,000-60,000 tons of steel structure.

You need a product

Related Searches

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Guangdong

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union