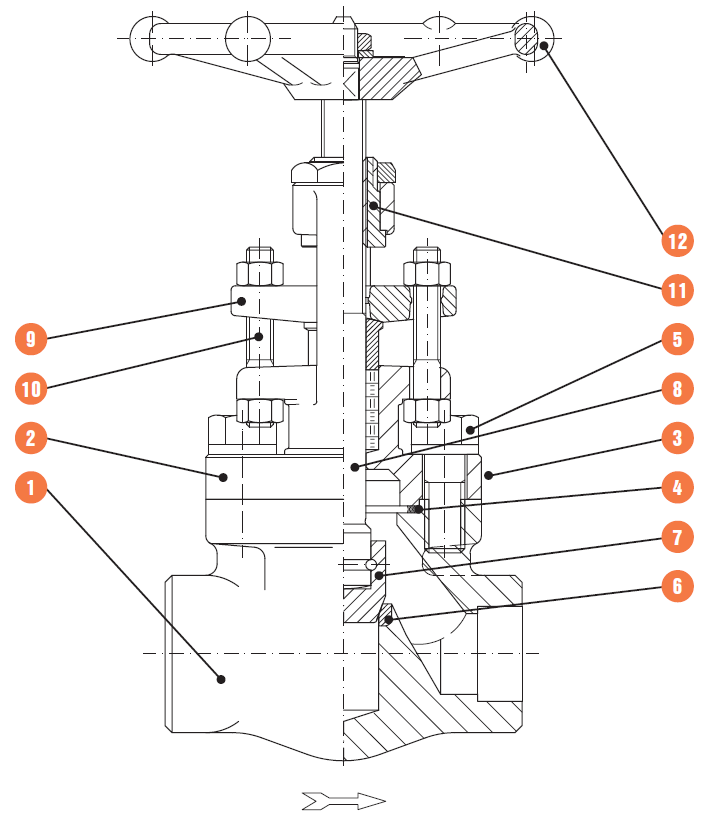

Forged Steel Bolted Bonnet Globe Valve

group nameFORGED STEEL VALVE

-

Min Order1 piece

brand nameRST/OEM

payment methodT/T, L/C, D/P D/A, MoneyGram, Westem Union, Cash

-

update timeMon, 28 Sep 2020 16:11:56 GMT

Paramtents

Size 1/2''~2''

Pressure 150LB~2500LB

Ends NPT/BSPP/BSPT/SW

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Forged Steel Bolted Bonnet Globe Valve

|

Brand

|

RST

|

||

|

1.Material

|

F304/316/304L/316L(CF8/CF8M/CF3/CF3M),A105,F11,F22,F51,LF2 etc.

|

||

|

2.Size

|

1/2’’~4’’

|

||

|

3.Certificates

|

ISO9001 & CE, TS

|

||

4.Port | Full Port | ||

5.Working Pressure | 150LB~2500LB/PN16~PN160 | ||

6.Connection Ends | NPT/BSPP/BSPT/BW/SW/RF, RTJ, etc. | ||

7.Working Temp | -20~425℃, or according to customer requirements for different industry. | ||

8.Suitable Medium | Water, Natural Gas, Oil and some corrosive liquid | ||

9. Operated | Handwheel Operated, Gear, Actuators | ||

10.Valve Test | 100% quality tested before delivery | ||

Shipment | |||

Delivery Time | 15~30 Days | ||

Package | Standard Exporting Plywood Case | ||

Shipping Port | Ningbo/Shanghai, China | ||

Shipping Terms | Exw, FOB, CFR, CIF, etc. | ||

Payment Terms | T/T, B/L, D/A, D/P, etc. | ||

30% prepayment, 70% balance paid before shipping or against copy of BL | |||

Valve Guarantee | 18 month after shipments | ||

Valve Sample | Sample available by RST VALVE | ||

MOQ | 1 SET |

You need a product

You May Like

- Nearest port for product export

- SHANGHAI, NINGBO

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Westem Union, Cash