Wood Plastic Machine WPC profile extrusion machine using recycled plastic for making WPC decking

group namePP PE WPC Profile Machine

-

Min Order1 set

brand nameHEGU

modelSJMS65/132

payment methodL/C, T/T

-

update timeFri, 25 Dec 2020 11:38:38 GMT

Paramtents

Product name WPC decking machine

Motor power 37KW

Screw material Bimetallic

Barrel Material SKD

Packging & Delivery

Weight25000.00kg / set

Min Order1 set

Briefing

2,Plastic wastage recycling PP PE

3,turnkey project service

4,high quality and output

Detailed

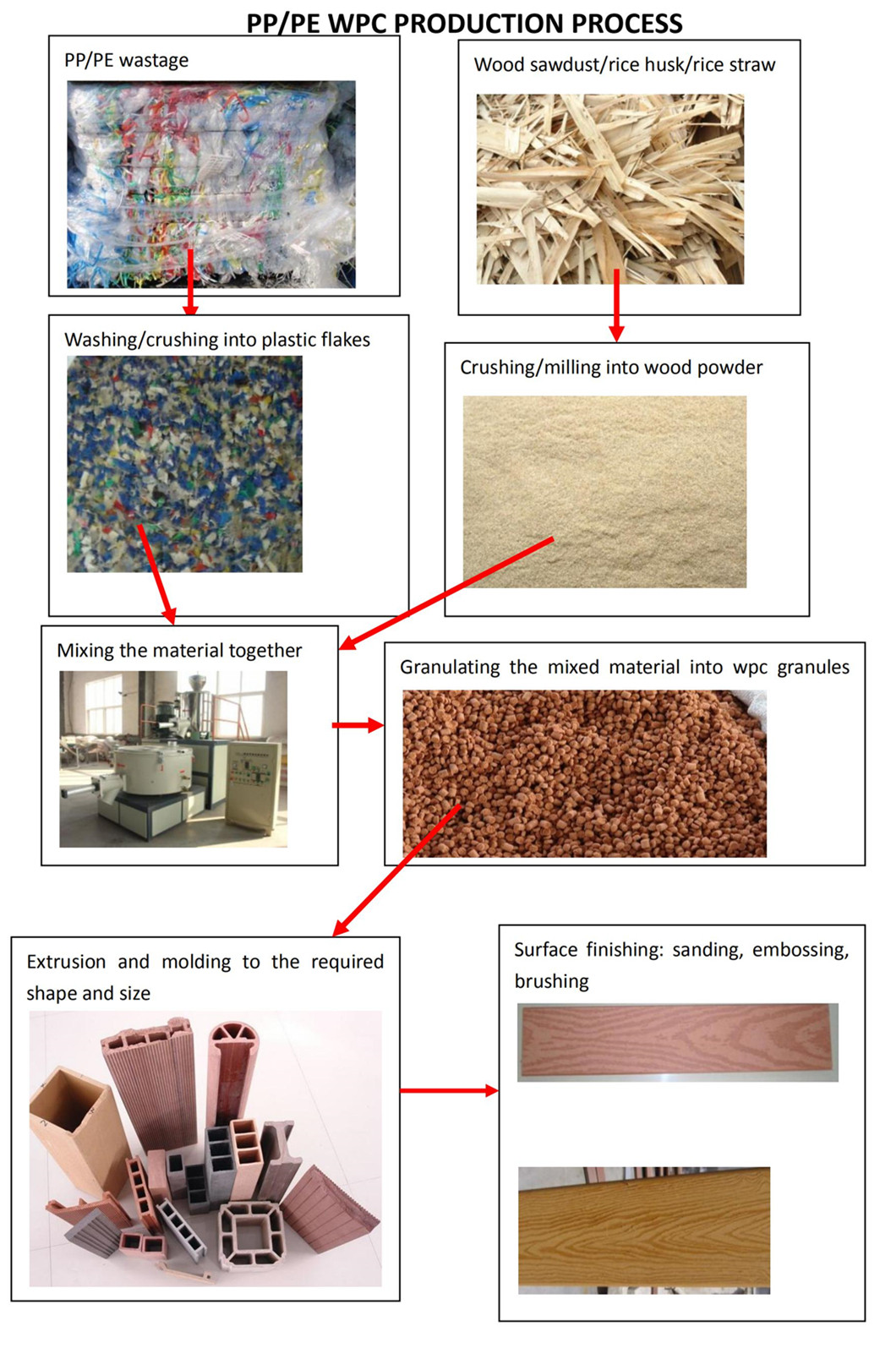

Wood powder milling machine

The wood powder milling machine is composed of rough crushing device, storagebin, miller part, rotational flow tank, pulse dust collector, etc. This machine can continuously produce the wood powder in 40-100 mesh. The wood powder can be used to make WPC products.

PP/PE WPC granulation machine for making WPC granules

The machine adopt high quality parallel double extruder, which help the plastic completely be merged with wood and chemical additives. Double screw extruder also has the advantages of high output and good plasticization. The produced PP/PE WPC granules will be used to produce the WPC profiles

PP/PE WPC profile extrusion line with mold to make wpc products

The PE WPC profile extrusion line is suitable for producing the hollow/solic PE WPC profiles. This profile has the advantage of fireproof, waterproof, anticaustic, moisture proof, moth proof, mildew proof and environment friendly. It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor lanscapes, pallets etc.

Wood plastic composite material, WPC is booming in recent years as a new type of composite material. WPC use polyethylene, polypropylene and PVC etc, instead of the usual resin adhesive, mix with more than 35% to 70% of wood powder, rice husk, straw waste plant fiber blend into wooden material, then through extrusion, mould pressing, injection moulding processing put out to board and profile. It mainly used in building materials, furniture, logistics packaging industries.

Wood-plastic composites contain plastics thus have good elastic modulus. In addition, as WPC contains fiber and classics to mix adequately with plastic, it has the physical mechanical property such as resistance to pressure, resistance to bending comparing to hard wood. And its durability is better than average woodiness material apparently. The surface hardness is high, generally 2-5 times than wood.

Comparative advantage of WPC

For now, WPC material is a little more expensive than wood. But the cost is reducing as the manufacturer is finding more efficiency producing method and using recycling plastic. Even though the WPC cost higher, customers would like to pay more on it because of the advantage of this composite material.

1. It is environment friendly.

It used recycling material

No need to be embalmed.

2. No need of daily maintain, long usage life than the wood

No moisture absorbtion, no decay, insect control, no cracking, no deformation.

Not sensitive to cold and hot environment.

3. Polyolefin wood-plastic composite have good mechanical properties and can be widely used as load-bearing structural materials.

4. 95% of the raw materials of polyolefin wood-plastic materials are recycled materials, so the cost is relatively low and the products can be 100% recycled.

5. PVC WPC composite material increase impact strength and reduces specific gravity through micro foaming, which is truly imitated wood.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash