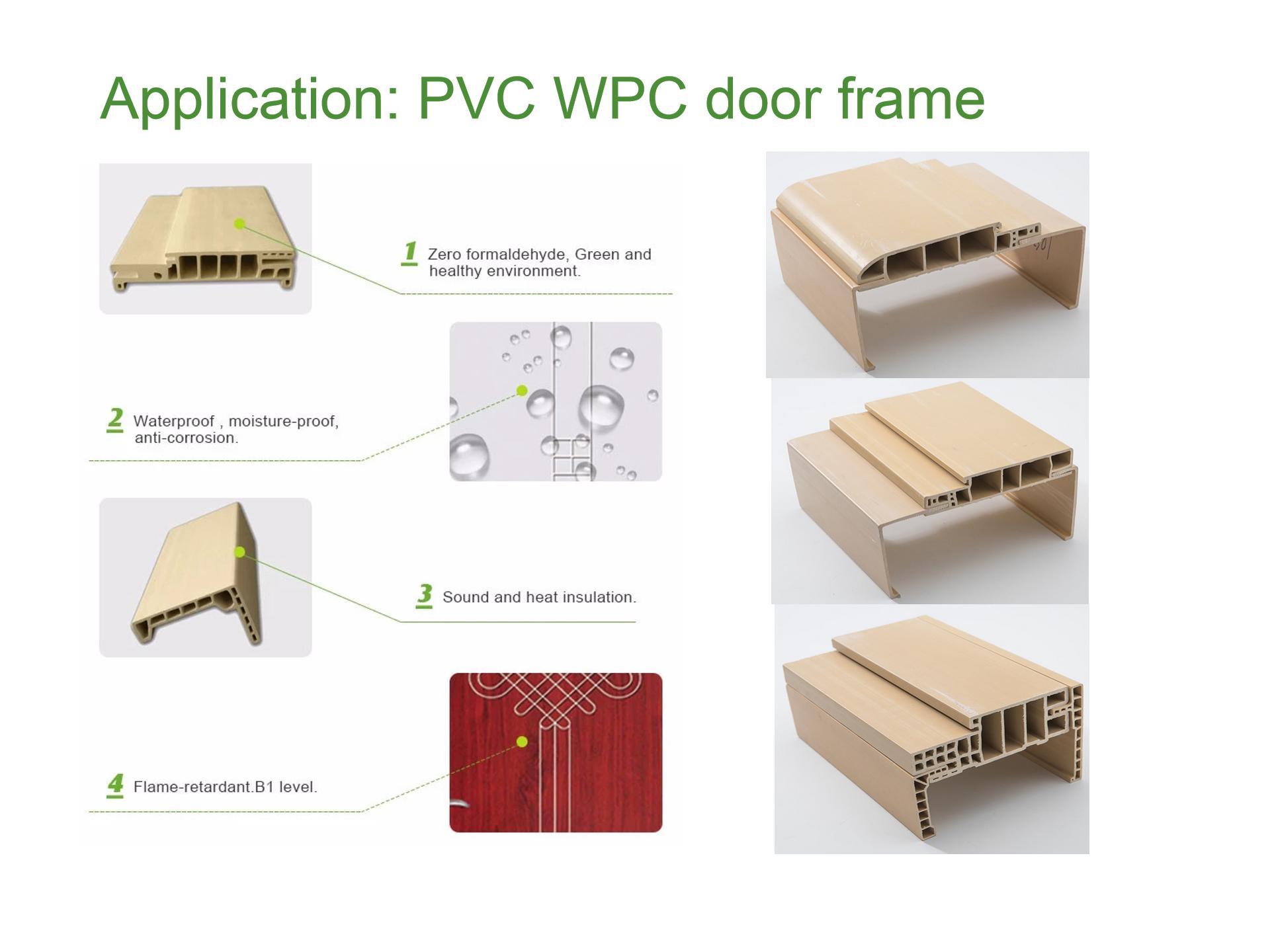

Solid WPC door frame making machine

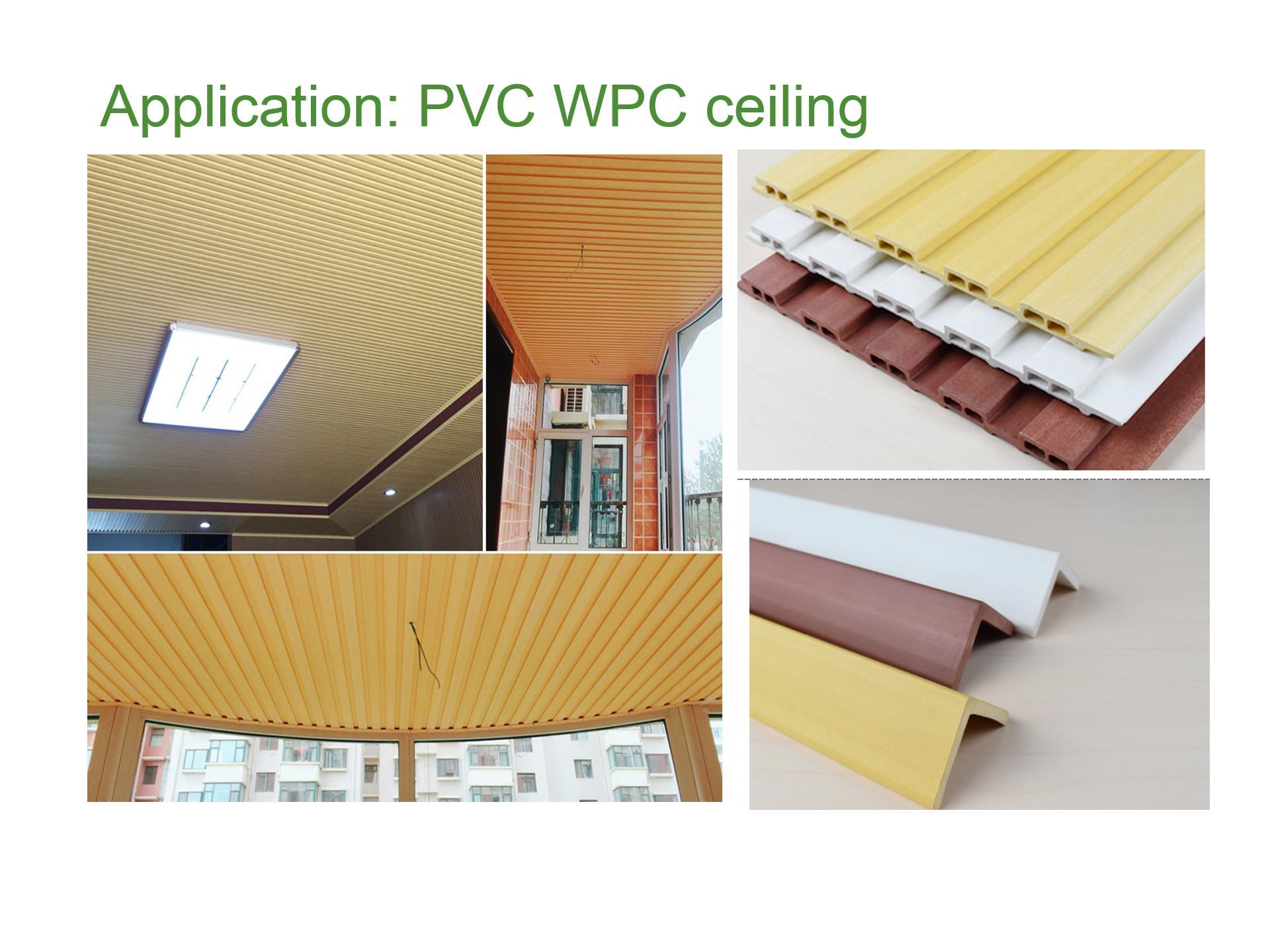

group namePVC WPC Profile Machine

-

Min Order1 set

brand nameHEGU

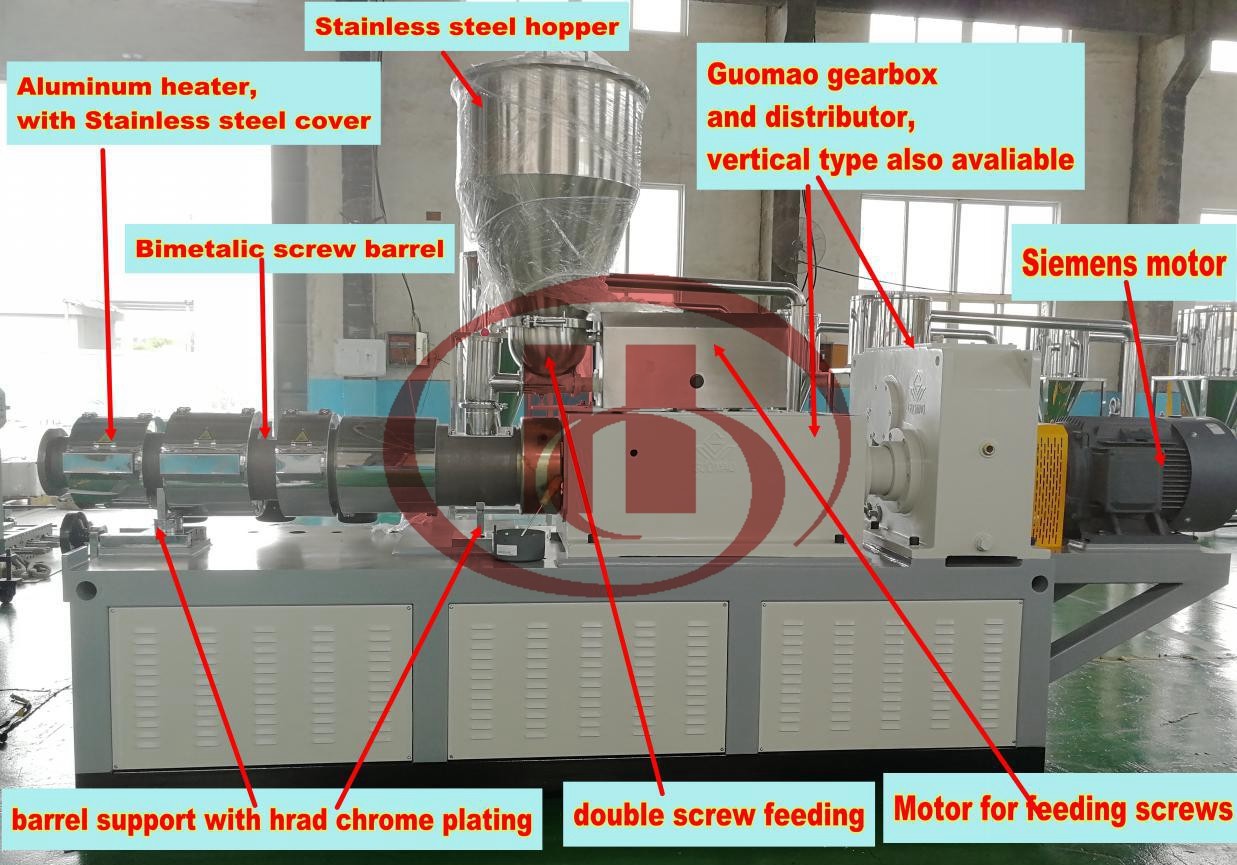

modelSJMS65/132

payment methodT/T, L/C, Cash

-

update timeThu, 20 Aug 2020 09:03:42 GMT

Paramtents

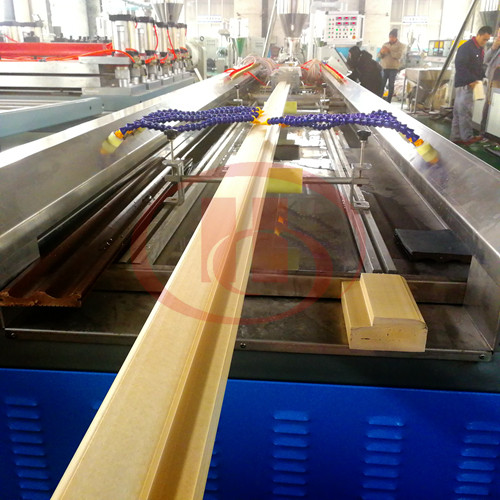

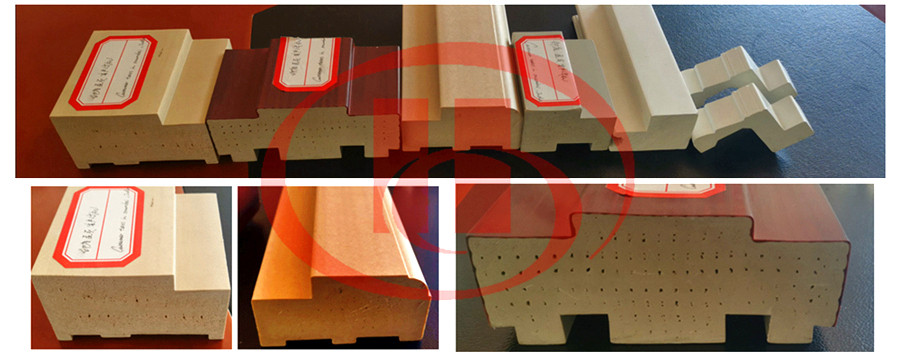

machine WPC door frame making machine

Packging & Delivery

Weight25000.00kg / set

Min Order1 set

Briefing

Detailed

|

Item

|

Machine

|

|

01

|

Auto Spiral screw feeder

|

02 | 65/132 Conical double screw Extruder |

03 | Water and vacuum Calibrating machine |

|

04

|

Haul off machine

|

|

05

|

Cutting machine

|

06 | Product stacker |

Material:38CrMoALA

Bimetallic Material: Tungsten Carbide alloy

Hardness After Hardening&Tempering:HB280-320

Nitrided Hardness:HRC55~58

Nitrided Case Depth:0.45mm-0.7mm

Nitrided Brittleness:Less than Grade 2

Surface Roughness:Ra0.4um

Screw Straightness:0.015mm

Bimetallic Hardness:HRC65

Bimetallic Depth: 2.5 mm

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash