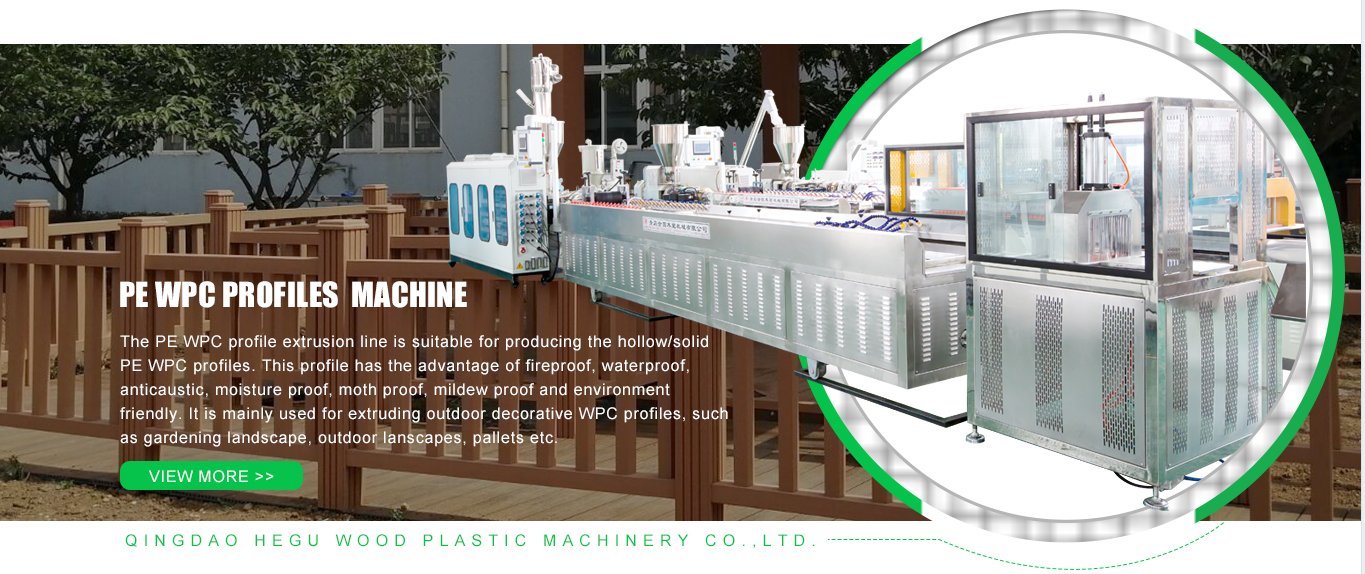

wood plastic composite extruder specifications Wood Plastic WPC profile machine Manufacturer China

group namePP PE WPC Profile Machine

-

Min Order1 set

brand nameHEGU

modelHG-65/132

payment methodL/C, T/T

-

update timeWed, 25 Nov 2020 14:46:06 GMT

Paramtents

wood plastic composite machine wpc extruder machine

Packging & Delivery

Min Order1 set

Briefing

Detailed

|

Model

|

Main motor power

|

Extrusion Capacity

|

Max.Product width

|

|

SJMS51/105

|

22KW

|

120-150 KG/H

|

300mm

|

SJMS65/132 | 37KW | 150-240 KG/H | 600mm |

|

SJMS80/156

|

55-75KW

|

300-400 KG/H

|

1200mm

|

|

SJMS92/188

|

110KW

|

450-550 KG/H

|

2500mm

|

SJMS80/173 | 75-90KW | 350-450KG/H | 1500mm |

|

Machine

|

Plastic Raw material

|

Wood Percentage

|

Application

|

PP PE WPC profile making machine | Recycled PP PE plastic | 60-70% | WPC decking, wall cladding, WPC fence, WPC handrail, WPC house, WPC pergola, WPC gazebo, |

|

PVC WPC profile making machine

|

Recycled PVC and new PVC

|

20-40%

|

WPC door frame, WPC window profile, WPC wall panel, WPC ceiling panel, WPC skirt panel, WPC decoration profiles

|

|

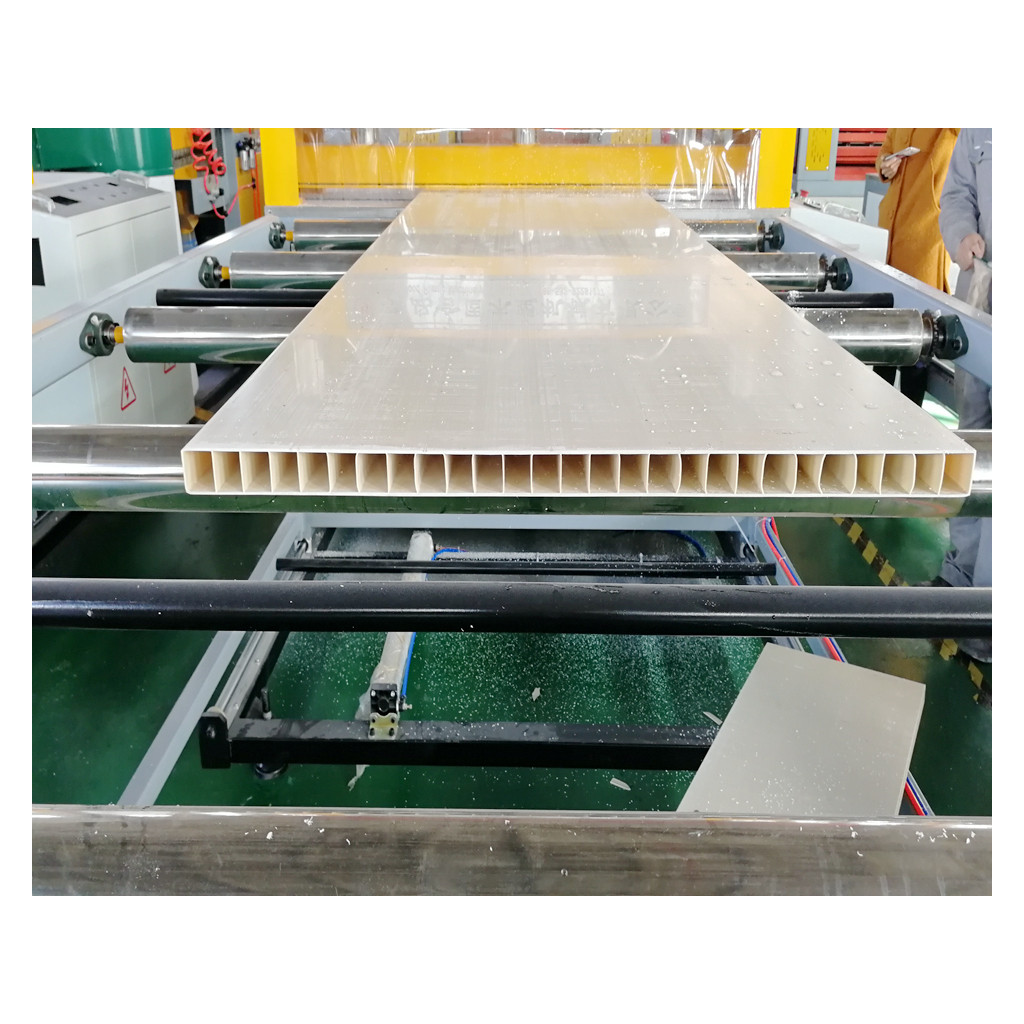

PVC WPC hollow door making machine

|

Recycled PVC and new PVC

|

20-40%

|

WPC door panel, WPC kitchen cabinet

|

|

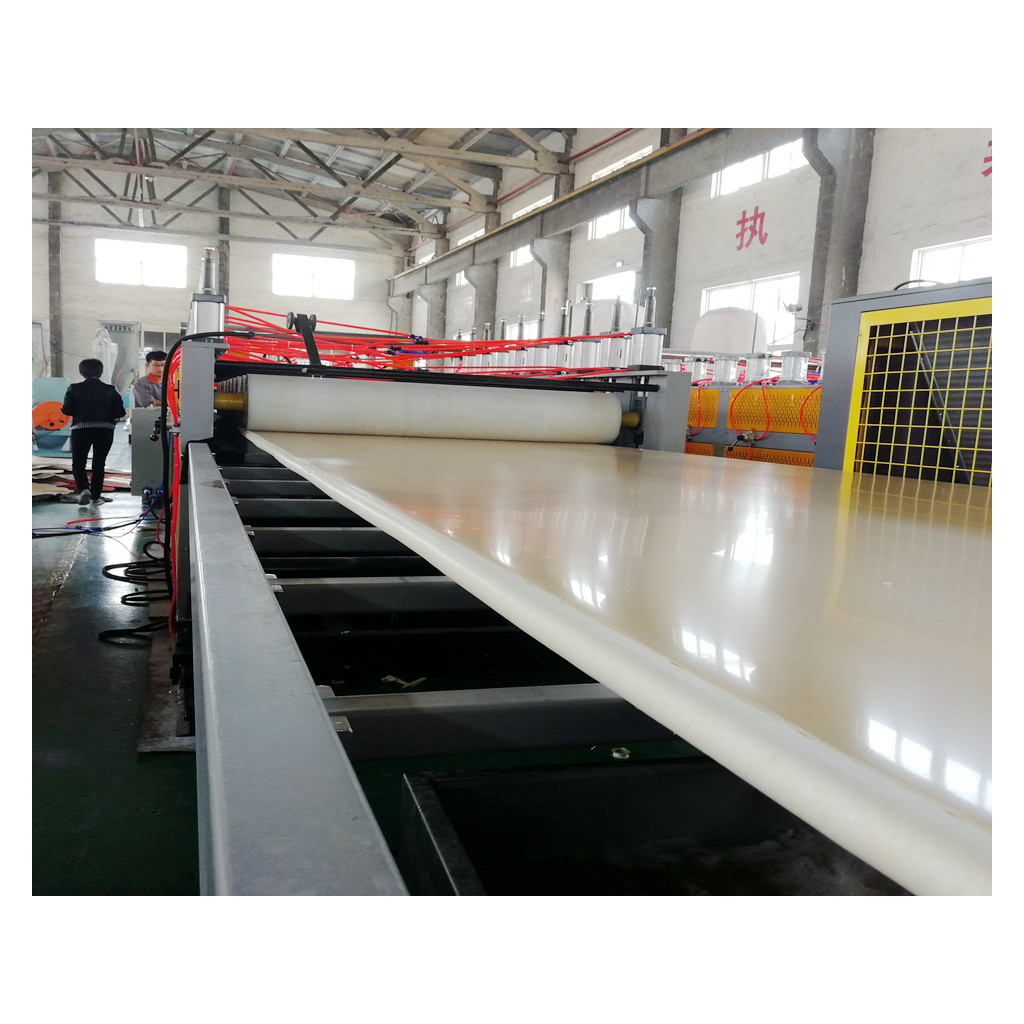

PVC WPC foam board making machine

|

Recycled PVC and new PVC

|

10-30%

|

WPC furniture board, WPC construction formwork, WPC partition wall

|

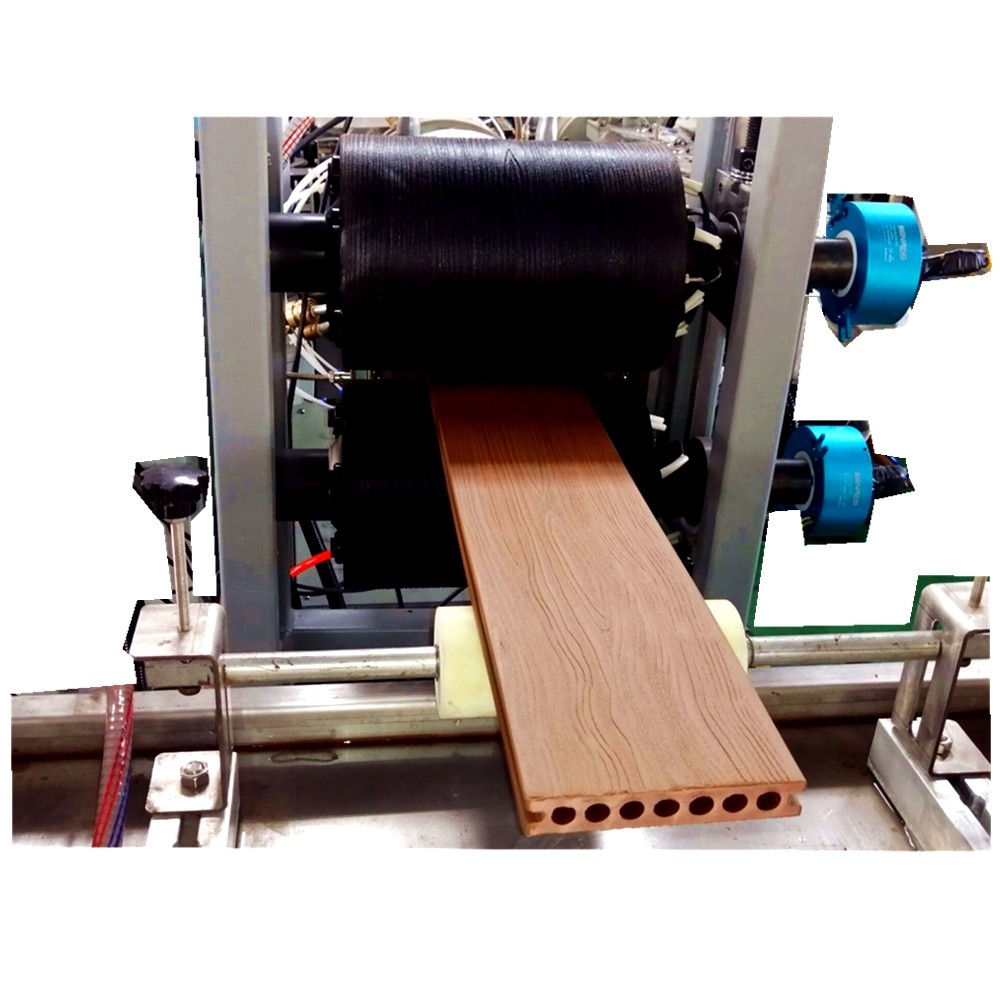

PP/PE RECYCLED WOOD PLASTIC COMPOSITE WPC PROFILE MAKING MACHINE

profiles. This profile has the advantage of fireproof, waterproof, anticaustic, moisture proof, moth proof, mildew proof and

environment friendly. It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor lanscapes, pallets etc

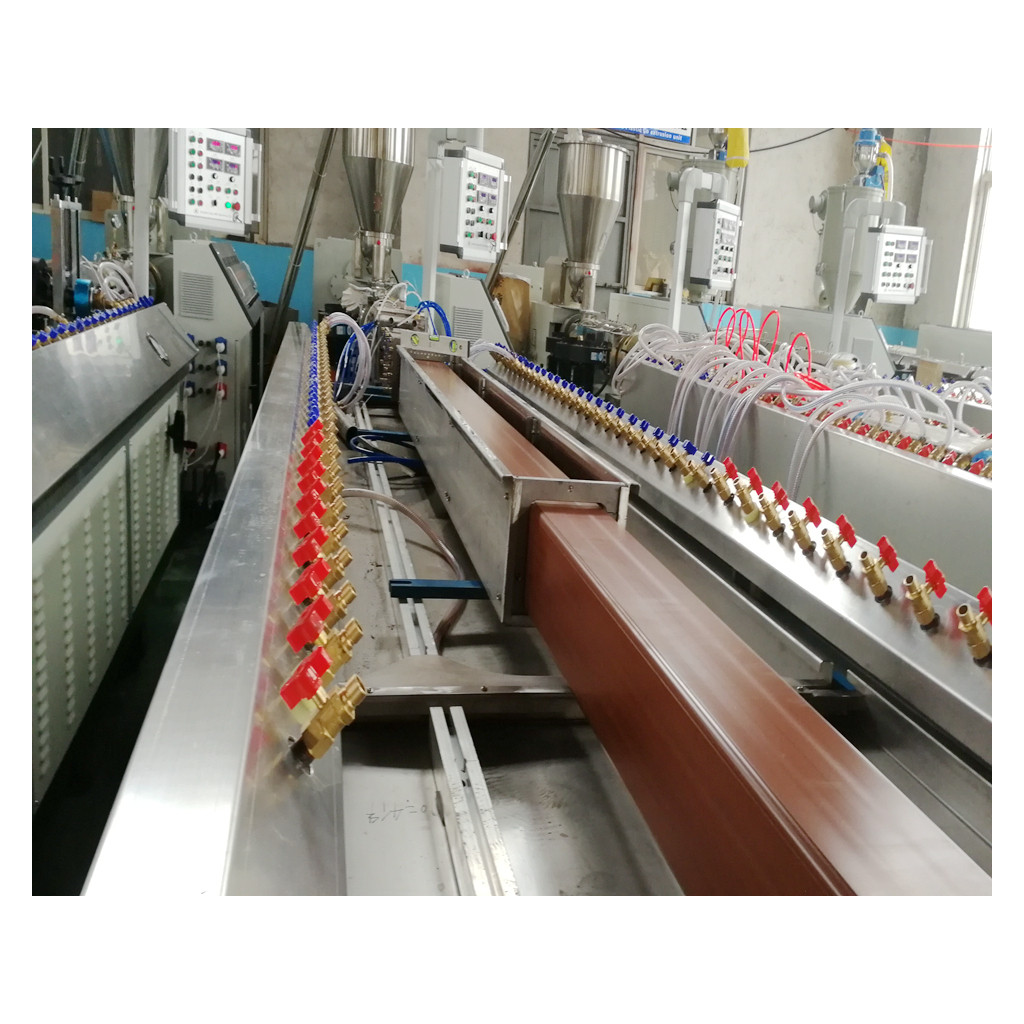

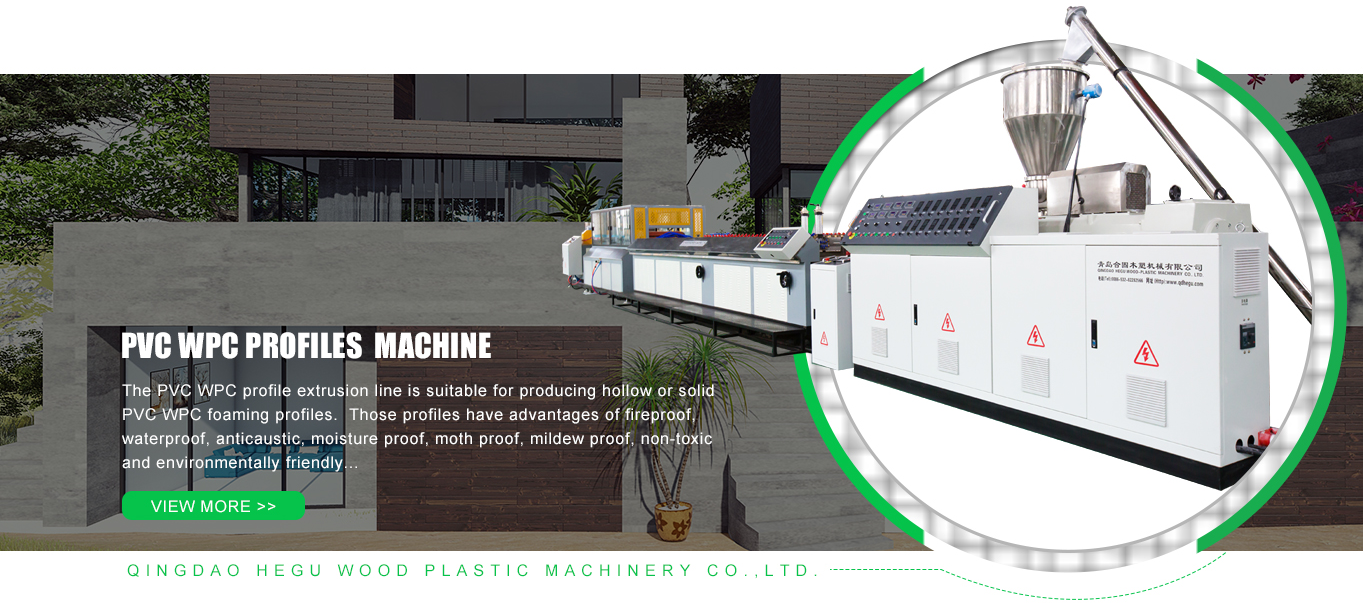

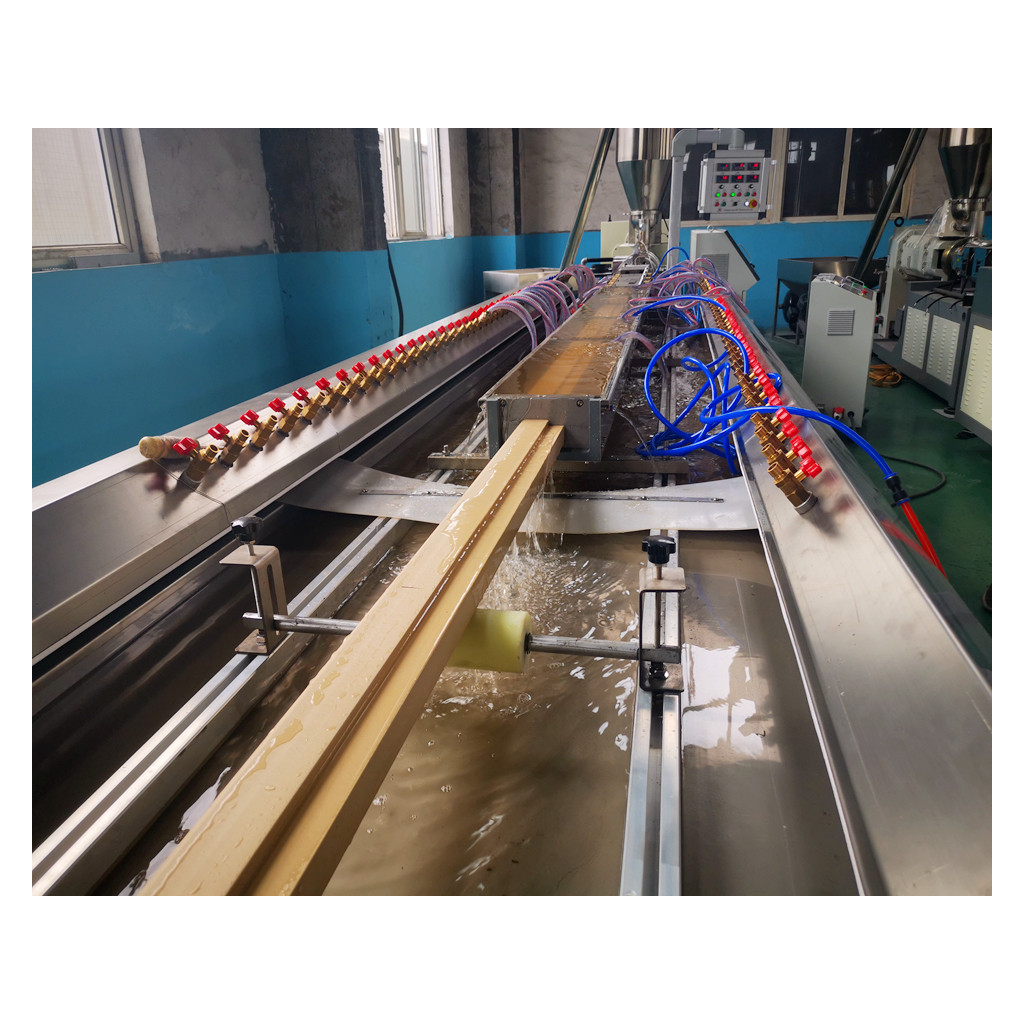

PVC WOOD PLASTIC COMPOSITE WPC PROFILE MAKING MACHINE

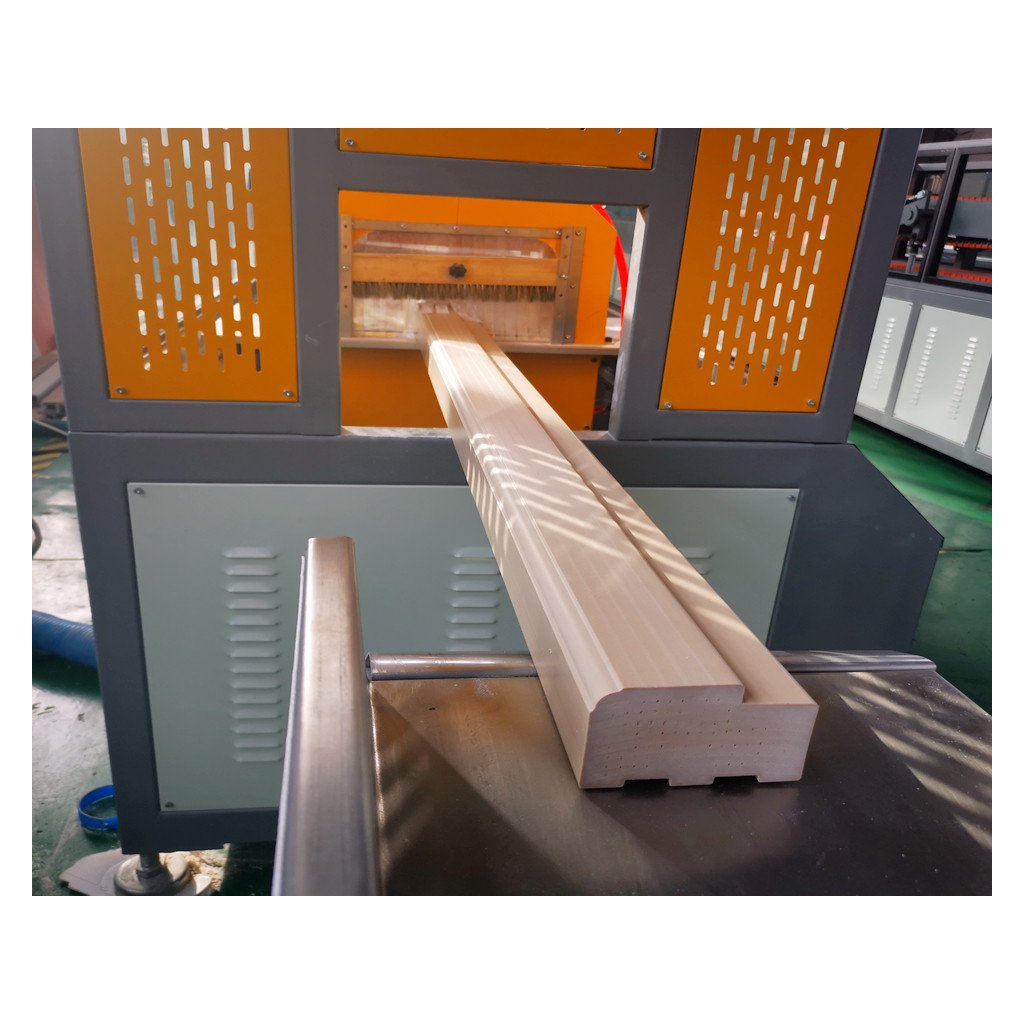

foaming profiles. This profiles have advantages of fireproof, waterproof, anticaustic, moisture proof, moth proof, mildew proof, non-toxic and environmentally friendly. The profiles are widely used in the fields of interior decoration, furniture making, such as door frame, skirting, photo frame, plastic door and window profiles.

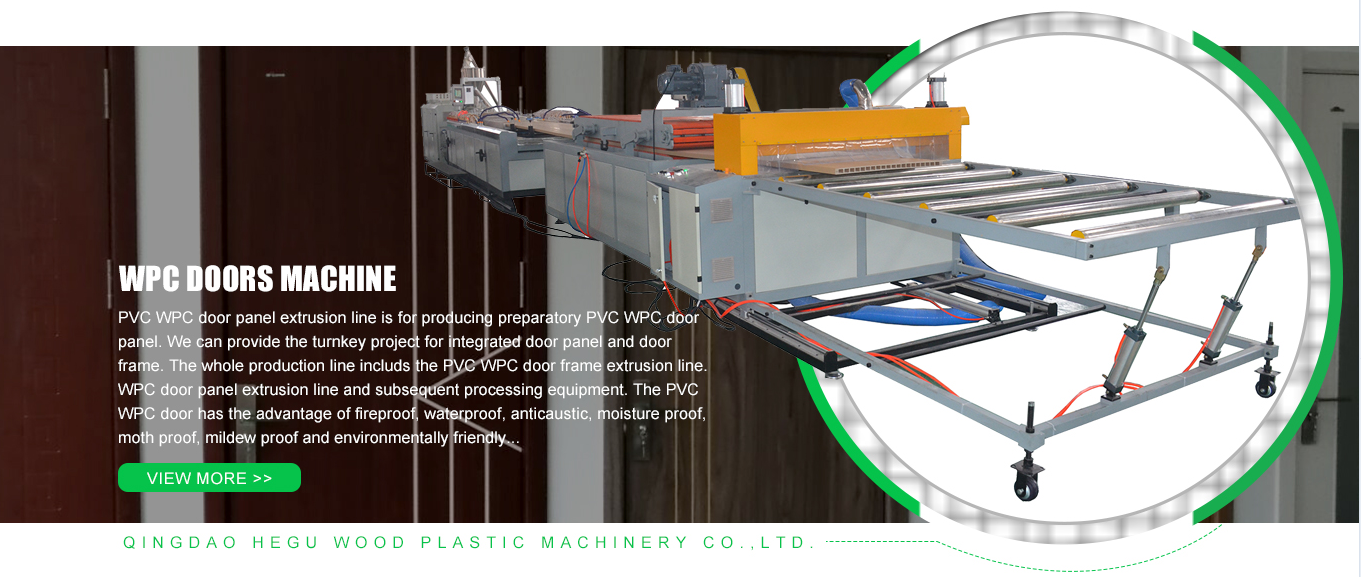

PVC WPC door making machine

provide the turnkey project for integrated door panel and door frame. The whole production line includs the PVC WPC door frame extrusion line. WPC door panel extrusion line and subsequent processing equipment. The PVC WPC door has the advantage of fireproof, waterproof, anticaustic, moisture proof, moth proof, mildew proof and environmentally friendly. The PVC WPC doors can be widely used in interior doors, hospital ward doors, school classroom door, various styles can be customized.

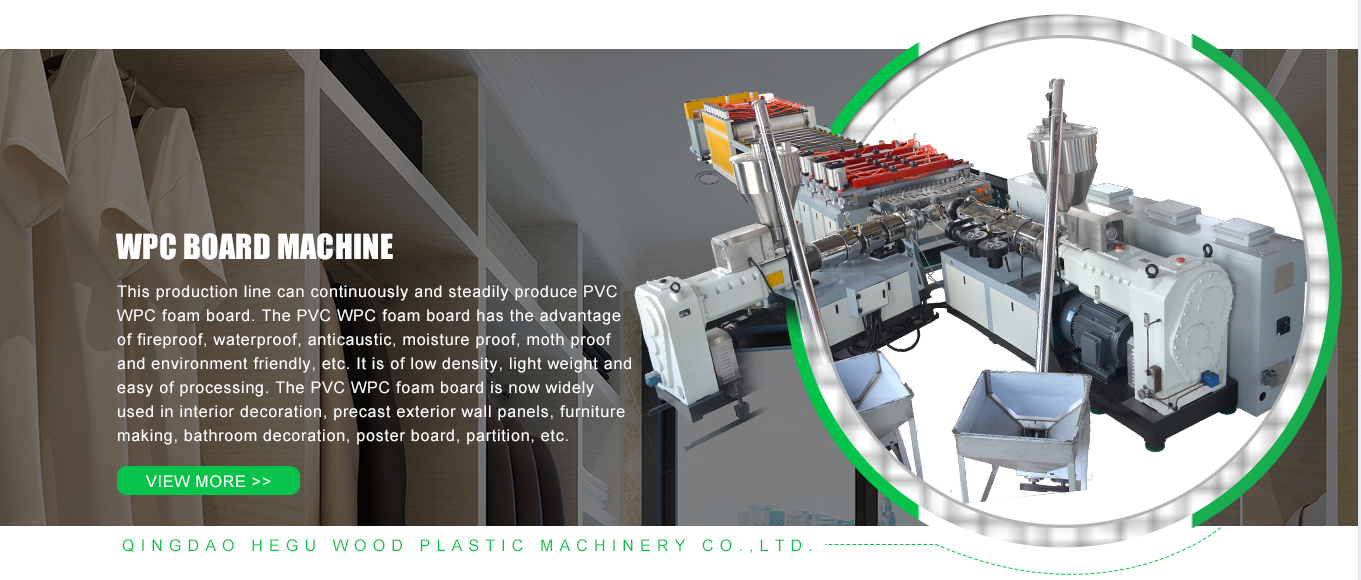

PVC WPC FOAM BOARD MACHINE

foam board has the advantage of fireproof, waterproof, anticaustic, moisture proof, moth proof and environment friendly, etc. It is of low density, light and easy of processing. The PVC WPC foam board is now widely used in interior decoration, precast exterior wall panels, furniture making, bathroom decoration, poster board, partition, etc.

2, has the appearance of solid wood and superior to the strength and arbitrariness of solid wood, and has excellent

anti-corrosion, waterproof, anti-insect, and flame retardant without solid wood. The product has no decorative pollution problems such as formaldehyde, ammonia and benzene.

3, unique formula technology, and through the interface strengthening treatment and special mixing molding technology, so that wood and plastic truly become one.

4, can be recycled, with biodegradable characteristics, protect forest resources and ecological environment, truly "green", in line with the "resource-saving, environment-friendly" social requirements.

5, "like plastic non-plastic, wood-like non-wood", because it has the dual advantages of wood and plastic and avoids its

shortcomings, it has become one of the most popular environmentally friendly products in outdoor architecture in recent years.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash