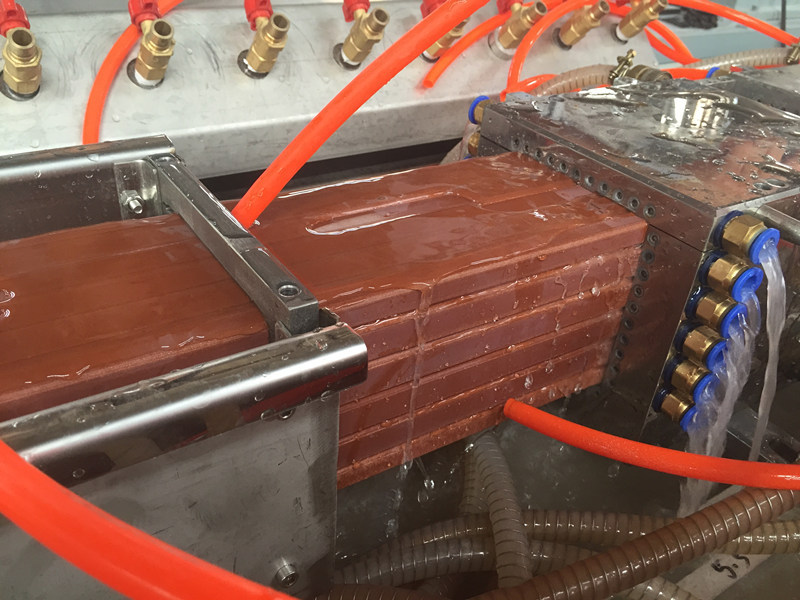

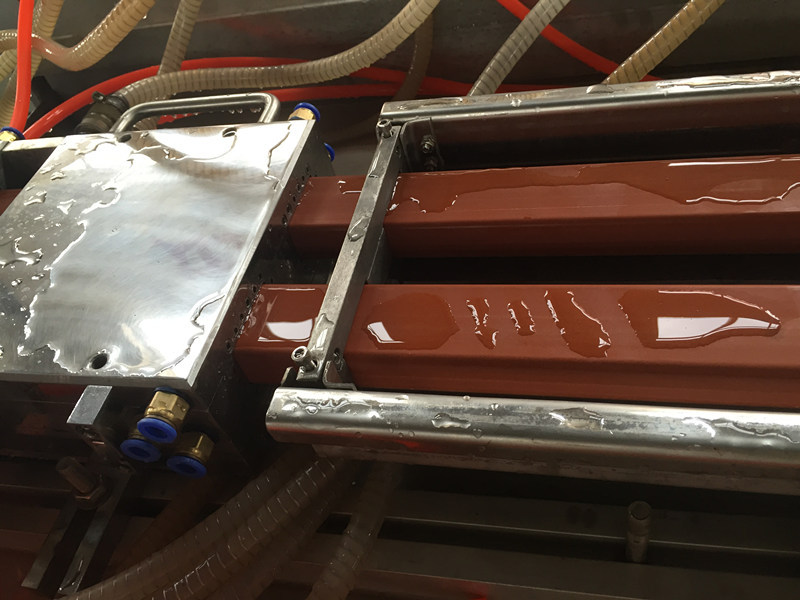

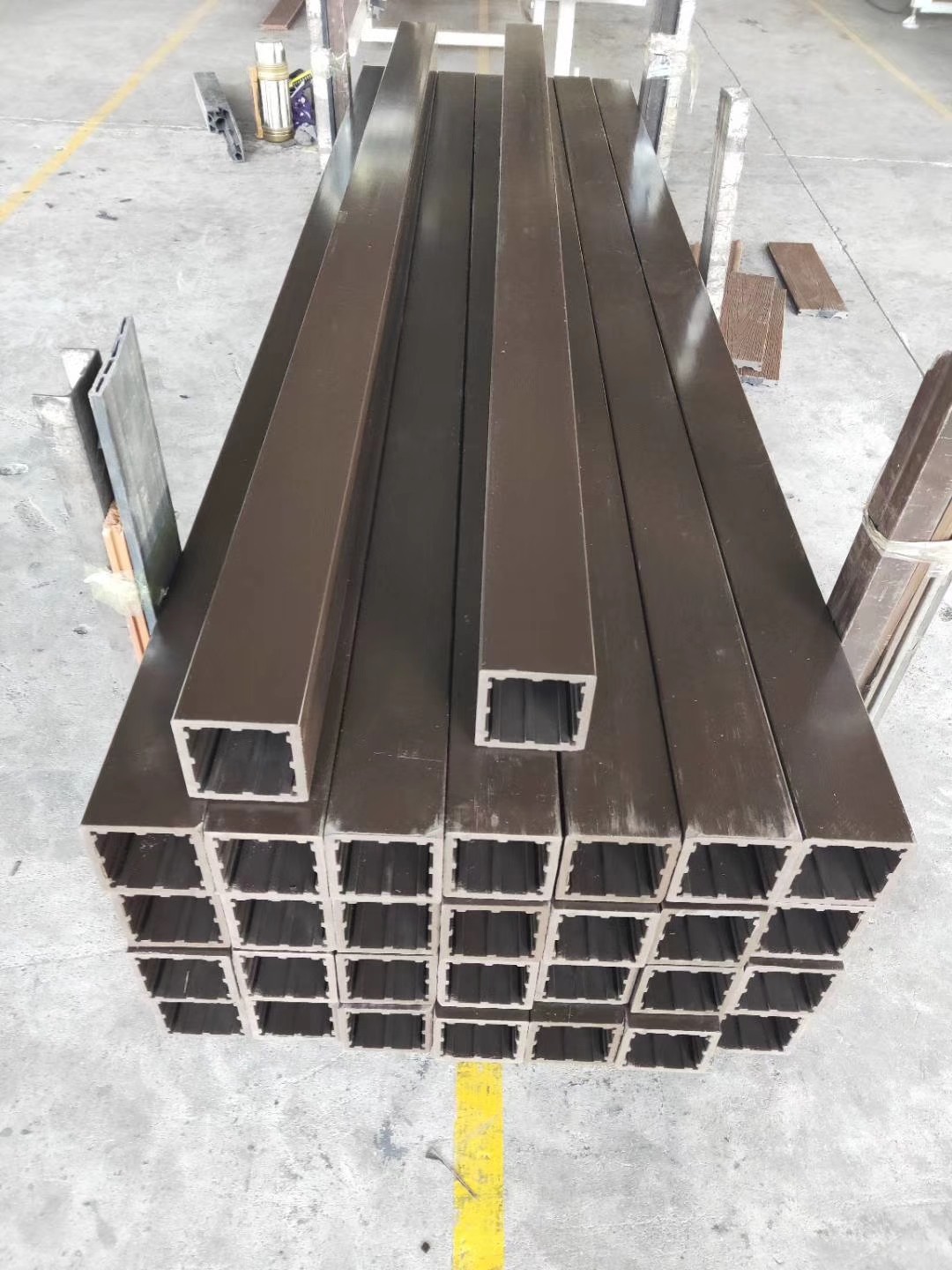

Waste PP PE and wood powder outside use decking production line

- US $38000.00

1 - 1 set

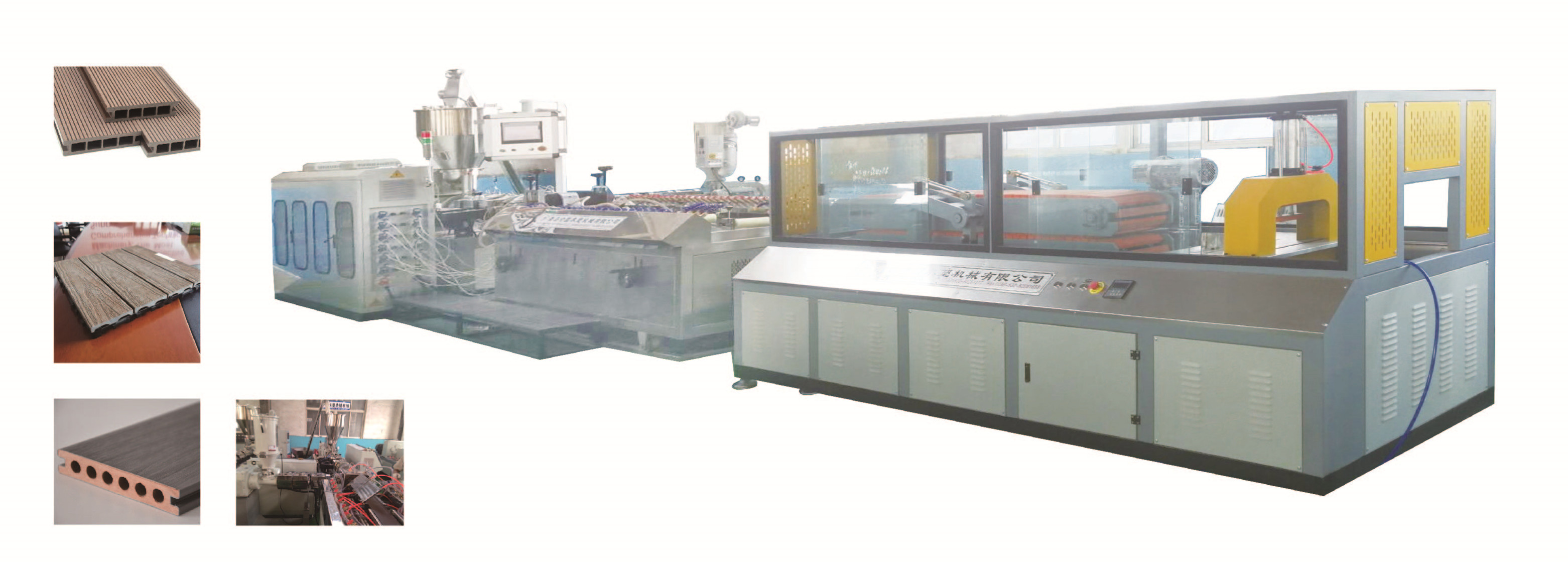

group namePP PE WPC Profile Machine

-

Min Order1 set

brand nameHEGU

modelSJMS65/132+SJ35

payment methodL/C, T/T

-

update timeThu, 20 Aug 2020 09:02:45 GMT

Paramtents

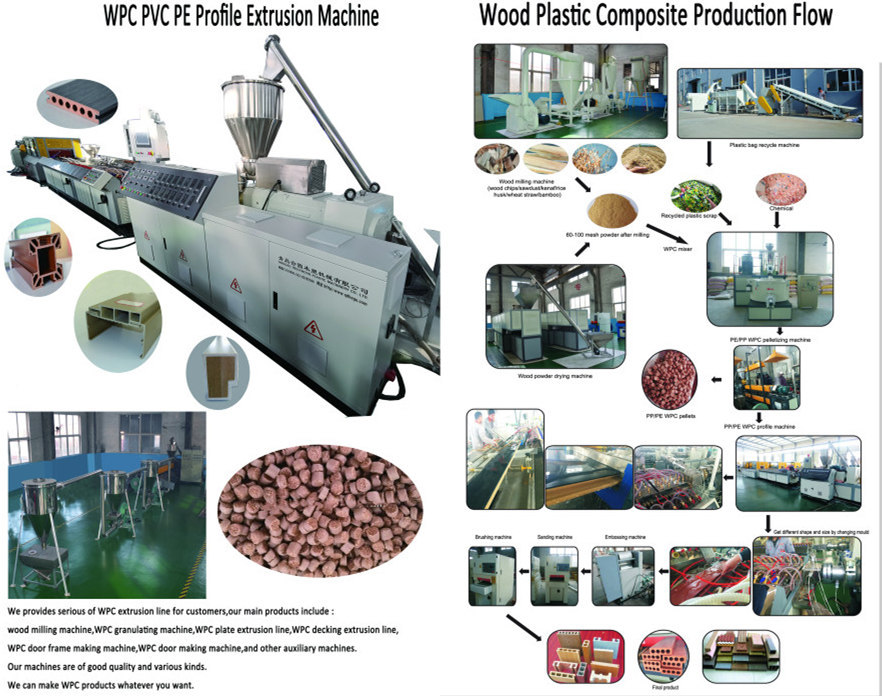

wood plastic composite machine WPC decking machine

WPC profile machine co-extrusion or common type

Application Outside landscape

Packging & Delivery

Min Order1 set

Briefing

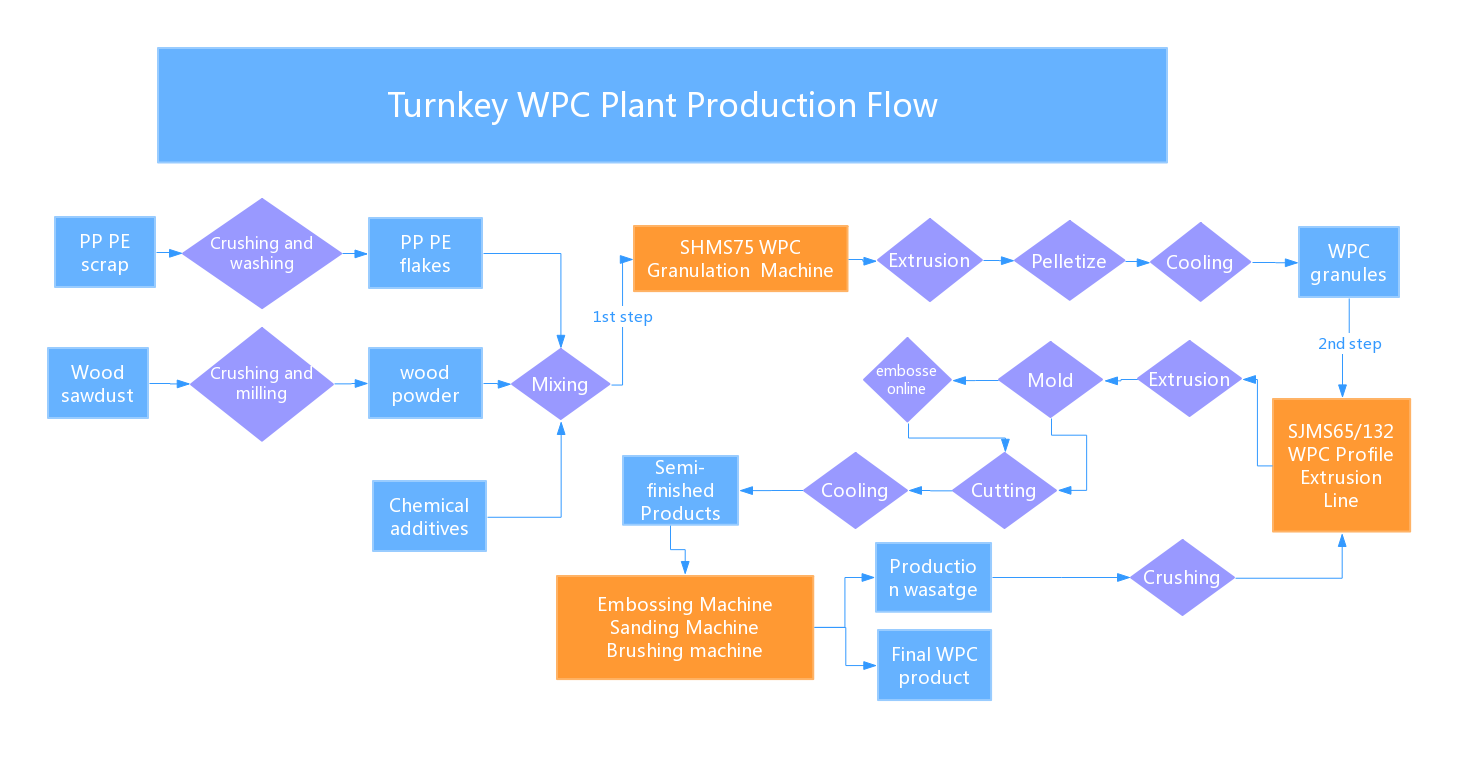

1,use recycled PP/PE

2,mix 70% wood

3,3D online embossing

4,co-extrusion wooden grain

Detailed

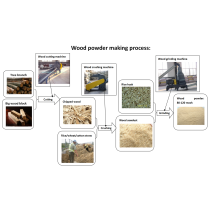

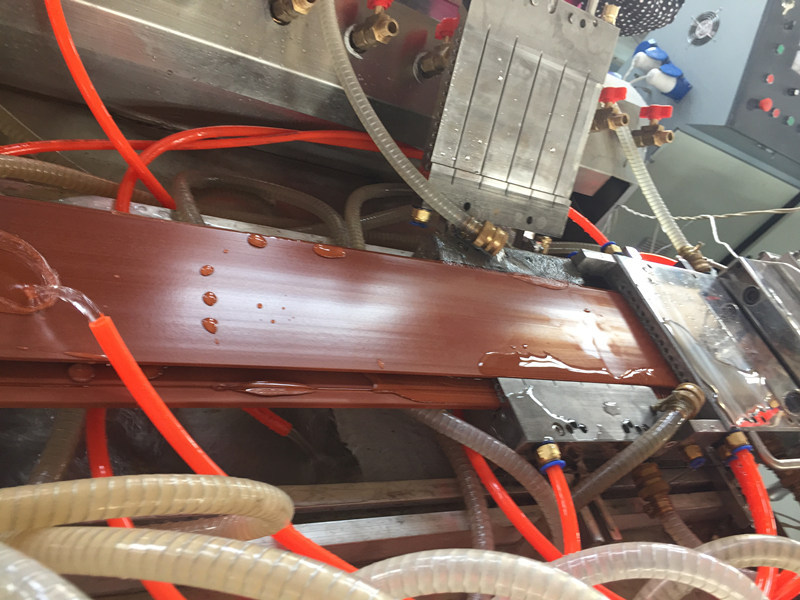

The structure of the wood flour is fluffy, and it is not easy to feed the extruder screw. In particular, the phenomenon of "bridge" and "holding pole" often occurs when the wood flour contains more water.

Feeding instability can cause extrusion fluctuations, resulting in reduced extrusion quality and yield. Feeding is interrupted, and the residence time of the material in the barrel is prolonged, which causes the material to burn and discolor, which affects the inherent quality and appearance of the product.

Forced feeding device and reasonable conveying method are adopted to ensure the stability of extrusion.

2.Exhaust during processing

The small-molecular volatile substances and water in the wood flour can easily cause defects in the product, and the pre-treatment cannot completely remove them. Therefore, the design of the exhaust system of the wood-plastic composite extruder should be given more attention than the ordinary plastic extruder, and multi-stage exhaust can be performed if necessary.

To a large extent, the better the exhaust effect, the better the quality of the extruded product

Screw: Bimetallic screw

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash