Low cost high speed wood core wpc solid door frame making machine

group nameWPC door making machine

-

Min Order1 set

brand nameHEGU

modelSJMS65/132

payment methodL/C, T/T

-

update timeThu, 20 Aug 2020 09:04:35 GMT

Paramtents

material PVC+wood WPC

Packging & Delivery

Weight25000.00kg / set

Min Order1 set

Briefing

1,material: WPC+wood

2,extruder: high output conical double screw

3,calibrator:high speed cooling

Detailed

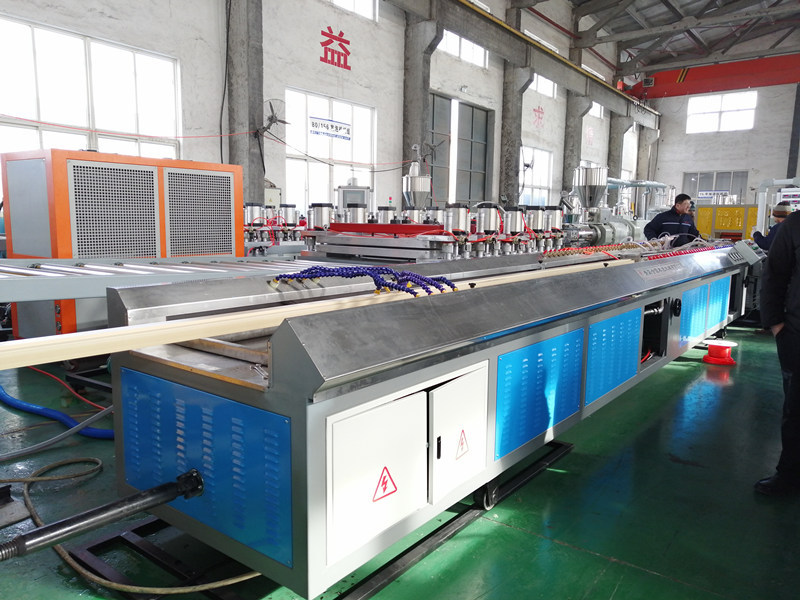

We are professional for wood plastic WPC machine, for adopting the market requirements, we have developed special co-extrusion technology for making low cost and high quality WPC+LVL door frame .

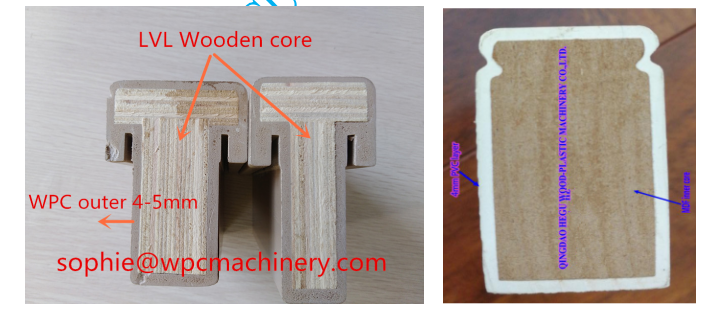

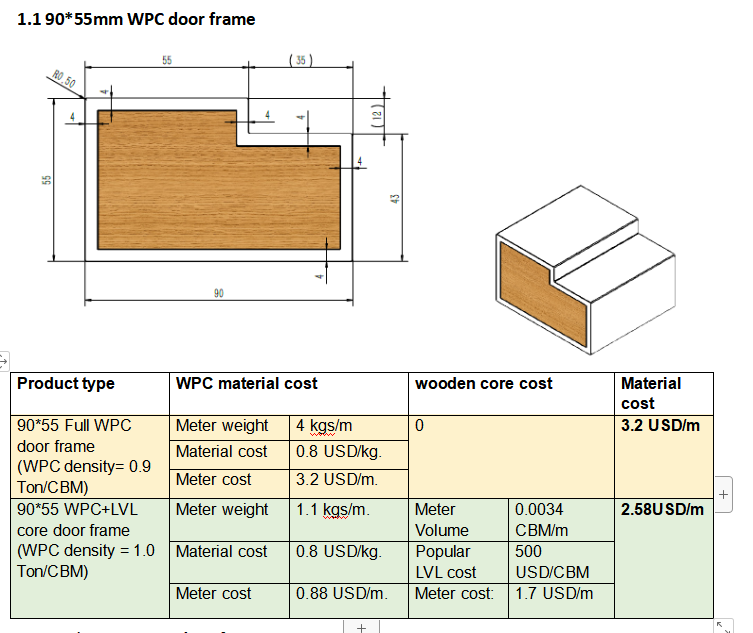

Avoid the disadvantage of traditional WPC solid door frame,such as heavy weight, high cost, easy deformation,weak nail/screw holding; we have developed WPC layer+ LVL core co-extrusion technology for making low cost WPC solid door frame

The inner core of the profile can be LVL wooden, MDF profile, Aluminum Profile, steel post.

The outer layer can be WPC layer or PVC layer, 4-5mm thickness shall be enough.

For the WPC+LVL door frame, as the inner core size is fixed and to be stably and continuously feeding to the extrusion line, so it is very easy for machine operators to control the product quality and forming size, and the 4-5mm outer WPC layer is also easy to be controlled by the die and calibrators. So the production defective rate and wast is very low.

For the WPC+LVL door frame,the inner is high density LVL (Laminated Veneer Lumber) which has advantage of high strength, high toughness, and resistant of fatigue failure caused by periodic stress, and high nail/screw holding strength. So the nail/screw holding strength of WPC+LVL door frame is as high as original LVL product.

|

Item

|

Machine

|

|

01

|

Auto Haul off device

|

02 | 65/132 Conical double screw Extruder with feeder |

03 | Water and vacuum Calibrating machine |

|

04

|

Haul off machine

|

|

05

|

Cutting machine

|

06 | Product stacker |

Advantage of WPC+core co-extrusion profile:Low cost

For the full WPC door frame, it is hard to be cooled fully inside, even if you increase the length of calibrator and water tank, the production speed is very limited to 0.3-0.5m/min because of the big thickness and high heat inside of the products. And the products after production shall also get problem of deformation because of afterheat inside of the products which can not be fully cooled on the extrusion line.

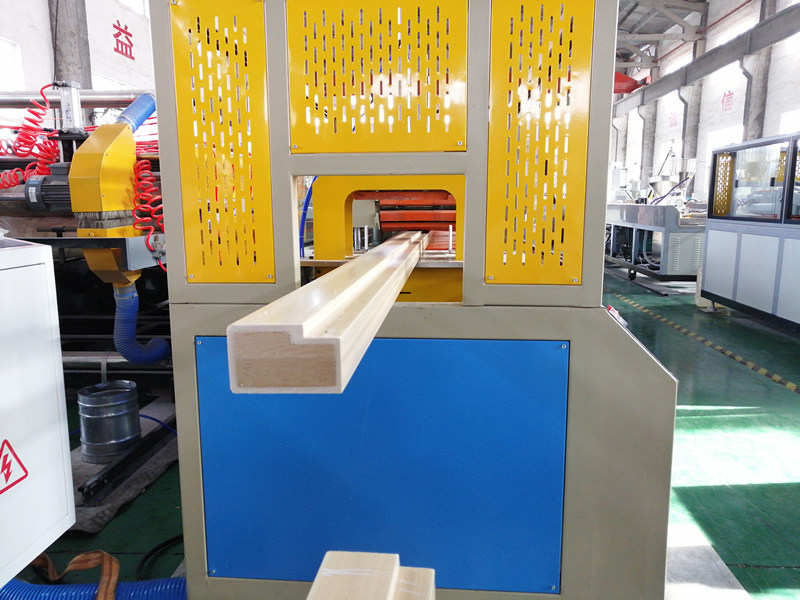

For the WPC+LVL door frame, the inner is LVL core which is in normal temperature, the LVL core shall only need to be heated at the surface before feeding to the extrusion line. And the WPC layer is only 4-5mm thickness, so the complete product can be easy cooled by the calibrators and water tank. So the production speed can be 0.5-0.8m/min and can be fully cooled on the extrusion line so that the product shall not get deformation after production.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash