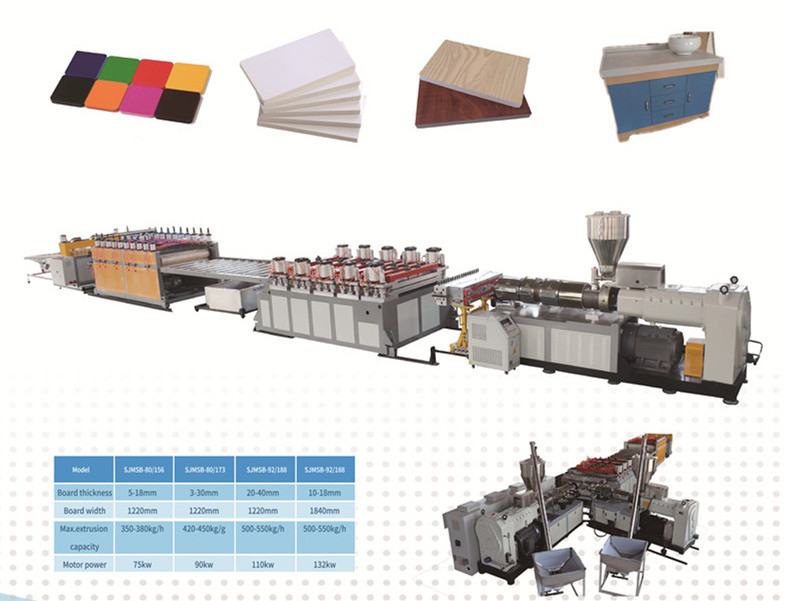

celuka foam board machine / pvc foam board extrusion machine

group nameWPC Board Making Machine

-

Min Order1 set

brand nameHEGU

modelSJMS92/188

payment methodL/C, T/T

-

update timeWed, 25 Nov 2020 15:01:13 GMT

Paramtents

machine WPC foam board machine

material PVC and wood powder

Packging & Delivery

Weight30000.00kg / set

Min Order1 set

Briefing

Detailed

|

Raw material

|

PVC, wood powder, CaCo3, Chemicals

|

|

Product width

|

1220mm

|

|

Product thickness

|

3-45mm

|

|

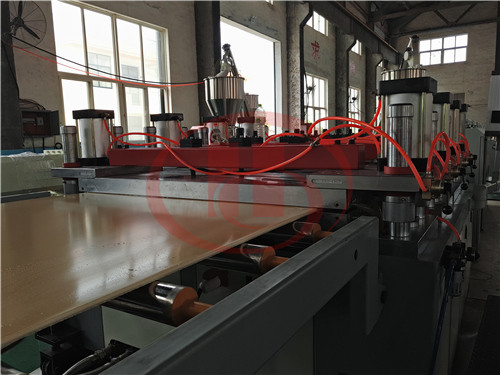

Machine size

|

30m*3m*4m (length*width*height)

|

Installation power | 200-250kw |

Water required | chilled water less than 18 degree |

WPC foam board extrusion line |

Product size |

Capacity |

SJMS80/156 |

Width: 1220mm, Thickness:3-18mm |

250-350kg/h |

SJMS80/173 |

Width: 1220mm Thickness: 5-35mm |

300-400kg/h |

SJMS92/188 |

Width: 1220mm Thickness: 5-45mm |

400-500kg/h |

1, We will provide the Feasibility Analysis Report for the wood-plastic project.

2, We will provide the model selection and technical parameter for wood-plastic machinery.

3, We will provide the design for the plant and electric power accounting for the facilities.

4, We will provide the design for wood-plastic formula according to the product requirements.

5, We will provide the technology of wood-plastic product surface treatment

6, We will provide technique training for operator.

7, We will provide solution for the practical problem during the production.

8, We will install and test the machine for free.

9, We will provide turnkey project to customers.

1, We shall help customer to prepare the material, electricity and other running conditions for the WPC factory running.

2, We will send our engineer's to customer's factory for installation all the machines and running all the machines

3, Our engineer shall also teach customer's engineer how to operate our machine.

4, If the customer's engineer has any problem in the cooperation, they can contact our service team to do online training.

1, We have developed our own formulation by many times of machine testing according to different raw material and product quality requirements.

2, Our PP PE WPC extrusion machine adopts double-step extrusion processing which can use max.70% wood powder and recycled PP/PE plastic flakes.

3, Our PVC WPC extrusion machine can make foamed WPC products by max.40% wood powder without material burning problem.

4, We also can help customer to develop its own formulation according to customer's raw material and market demands.

1, WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

2, SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

3, LIFELONG SERVICE: WE SHALL PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash