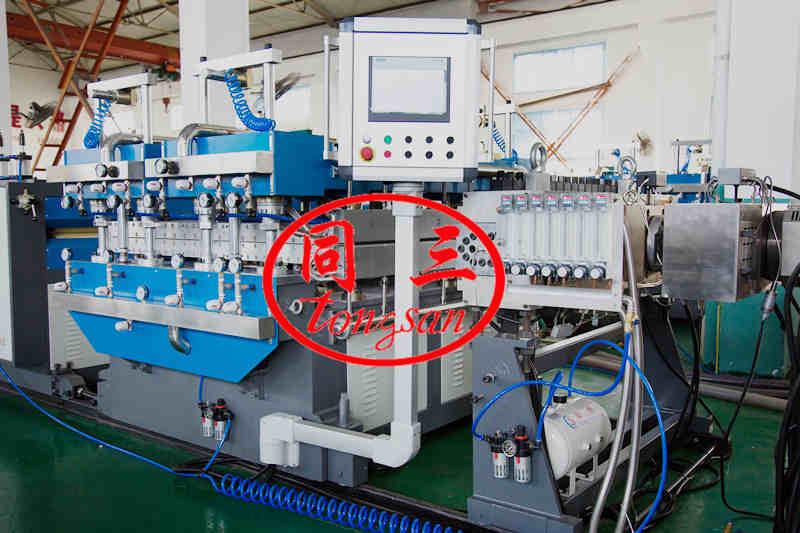

PC PP PE Plastic Light Weight Twin wall Advertising Printing Hollow Grid Sheet Extrusion Mechinery

- US $135000.00

1 - 1 piece

- US $134800.00

2 - 2 piece

- US $134600.00

3 - 3 piece

- US $134300.00

4 - 4 piece

- US $134000.00

5 - 5 piece

group namePlastic hollow sheet box making auxiliary machine

-

Min Order1 piece

brand nameQingdao Tongsan

model1860type

payment methodL/C, Western Union, MoneyGram, T/T, Paypal

-

update timeThu, 24 Sep 2020 13:18:11 GMT

Paramtents

Main extruder SJ100/36

Main motor power 55kw

Total installtion power 160kw

Actual power consumption 90kw

Sheet width 1220mm

Sheet thickness 1.5mm-12mm

Production speed 0.2-6m/min

Machine brand Qingdao Tongsan

Origin place Qingdao China

Output capacity 170-190kg/h

Motor brand Siemens

Temperature Controller Omron

Vacuum pump Taiwan Yuanli

Mold 1.5-6mm , 7-12mm

Delivery time 90 days

Packging & Delivery

Size300cm x 300cm x 300cm

Weight22000.00kg / piece

Min Order1 piece

Briefing

Detailed

Model |

Sheet width | Sheet thickness | Extruder Model |

Motor power |

TS-1400 |

1220mm | 2-6mm,7-12mm | 100/36 |

55-75kw |

TS-1860 |

1700mm | 2-6mm,7-12mm | 120/36 |

75-90kw |

TS-2300 |

2100mm | 2-6mm,7-12mm | 120/36 |

90-110kw |

TS-2600 | 2450mm | 2-6mm,7-12mm | 120/36 | 90-110kw |

TS-3000 | 2800mm | 2-6mm,7-12mm | 150/36 | 132kw |

Mould for PP corrugated sheet extrusion line

Mould

adopts high-quality alloy steel and throttling device to ensure even

pressure of feed influent at the mould lips, and also differential

action of up-down piece guarantee even thickness of the plate.

1, customized width and thickness

2, with hydraulic screen changer

3, with melting pump

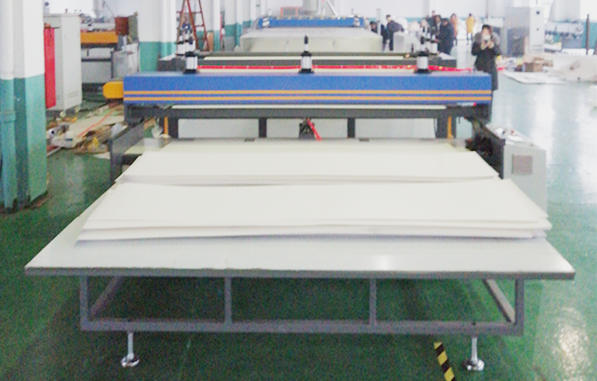

4, high quality mold with precision thickness controlCalibrating table for PP corrugated sheet extrusion line

Haul off device for PP corrugated sheet extrusion line

Heating oven for PP corrugated sheet extrusion line

Haul off device for PP corrugated sheet extrusion line 2nd

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow