Tongsan automatic die cutting machine for PP corrugated sheet boxes making

- US $35000.00

1 - 1 piece

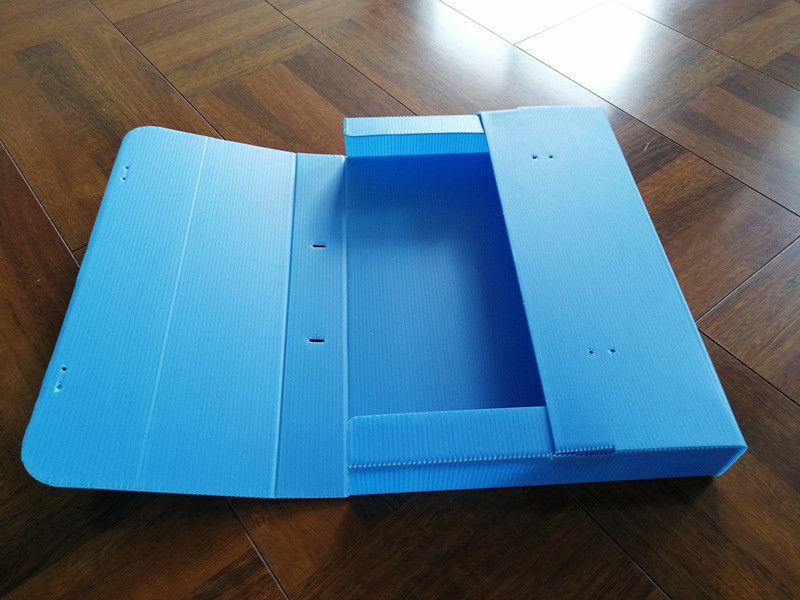

group namePlastic hollow sheet box making auxiliary machine

-

Min Order1 piece

brand nameQingdao Tongsan

modelTS-110

payment methodL/C, Western Union, MoneyGram, T/T, Paypal

-

update timeThu, 24 Sep 2020 13:17:25 GMT

Paramtents

Max. sheet size 1060×770mm

Min,sheet size 400×370mm

Max.die cutting size 1050×750mm

Gripper margin 8-17mm

Sheet range 90-2000g/m2(cardboard) 0.1-2mm(cardboard)≤4mm(corrugated)

Maximum cutting force 300T

Max. mechanical speed 7500s/h

Max. delivery pile height 1200mm

Max. feeding pile height 1350mm

Main motor power 11kw

Power rating 17.6kw

Overall machine dimensions 5050×4200×2260mm

Machine weight 15000kg

Packging & Delivery

Size200cm x 200cm x 200cm

Weight6000.00kg / piece

Min Order1 piece

Briefing

Detailed

Qingdao Tongsan Plastic Machinery co.,;td have been develop the PP hollow corrugated sheet making machine since 2015,now we have the machines for the PP hollow grid plate width from 1220mm to 2450mm and thickness from 1.5mm to 12mm.We have different model production line,such as the 1400 type PP hollow sheet extruder machine,1860 type PP corrugated sheet production line,2300 type PP hollow corrugated board making machine,2600type plastic hollow grid panel making machine,and for each model,we have the co0extrusion type for customer choose.The co-extruder type can use 20%-60% fillermatch for reduce the cost,so our customer can product the cost competitiveness sheet with goog quality.Our machine have the advantage of high output,easy operation,high precision,good products with smooth surface straight rib.

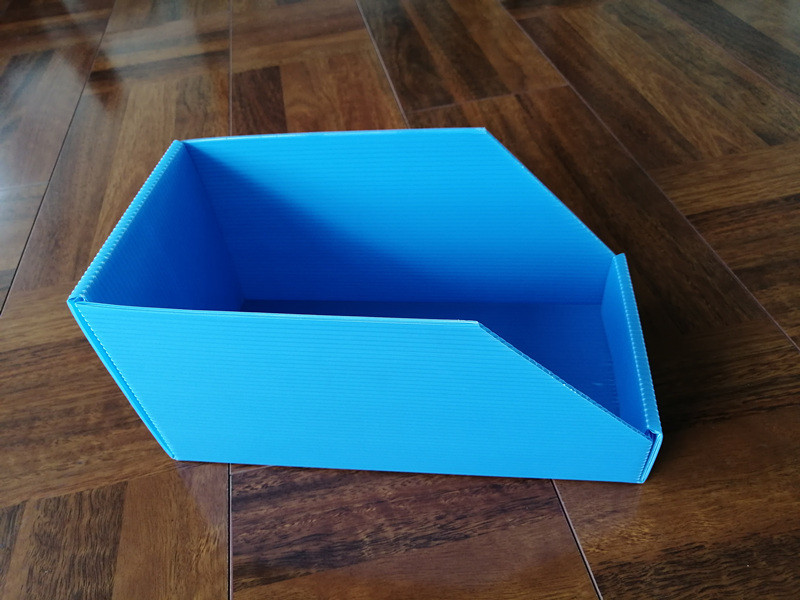

We can also provide all the auxiliary machines for the PP packing box.

Item

PP packing box making Machine

Note

01

Material Mixing machine

For mixing material, such as chemicals, color masterbatch, filling masterbatch, recycle material

02

PP hollow corrugated sheet extrusion line

For makeing Pp hollow corrugated sheet for required width and thickness.

width: 1200-2700mm

thickness: 2-12mm

03

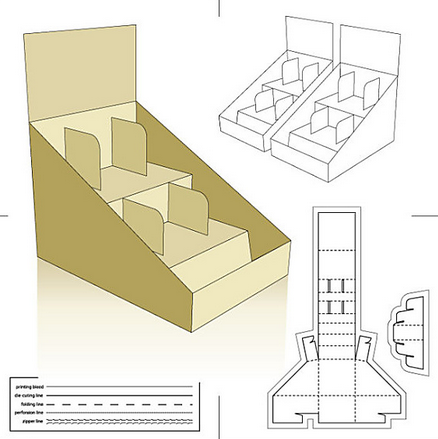

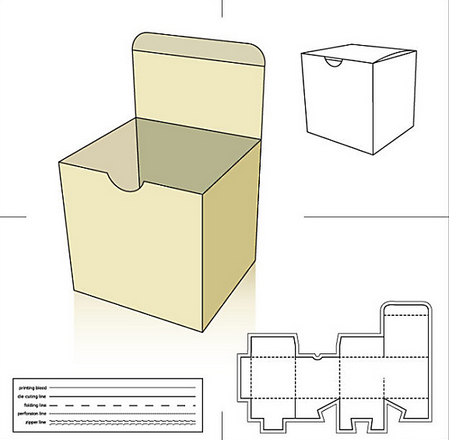

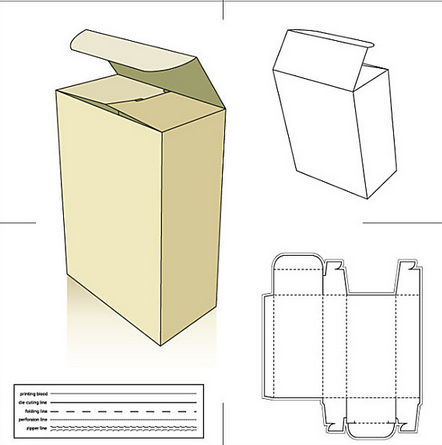

PP hollow sheet die cutting machine

For cutting the Pp sheet into required shape for folding box

04

PP hollow sheet printing machine

for printing logo and designs on the Packing box, there is different printing machine, such as single color printer, double color printer, four color printer.

05

PP hollow sheet welding machine

PP hollow sheet bookbinding machine

For folding the Pp hollow sheet into required box shape, welding machine and bookbinding machine both can work for it

The working principle of die cutting machine is to use die cutter, steel knife, metal mold, steel wire (or steel plate)

The engraved template) is pressed to a certain shape by applying a certain pressure to the stamp. If the entire printed product is cut into a single graphic product, it is called die cutting; if the steel wire is used to press the mark on the printed product or leave the bent groove marks as indentation; if the two templates are used, the mold is passed. Heating to a certain temperature, the pattern or font with a three-dimensional effect on the surface of the printed product is called bronzing; if one substrate is used on another substrate, it is called bonding; the other part except the genuine one is called Discharge; the above can be collectively referred to as die cutting technology

The die-cutting process is the most commonly used process for packaging printed matter. It is a combination of die-cutting knives according to the design requirements of the product to form a die-cutting plate. Under the action of pressure, the printed matter or other ring-shaped blanks are rolled into the desired shape or The forming process of the cut. The indentation process utilizes a crimping knife or a crimping die to press a line mark on the sheet by the action of pressure, or to bend and form the sheet at a predetermined position by using a rolling reel. Generally, the die-cutting indentation process is a process in which a die-cutting cutter and a crimping cutter are combined in the same template, and a die-cutting and indentation processing is simultaneously performed on the die-cutting machine, which is simply referred to as die-cutting. Process The main process of die-cutting indentation is: upper plate → adjust pressure → determine the rule → paste substrate auxiliary material → test die-cutting → formal die-cutting indentation → stripping → finished product winding or cutting into pieces → points package.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow