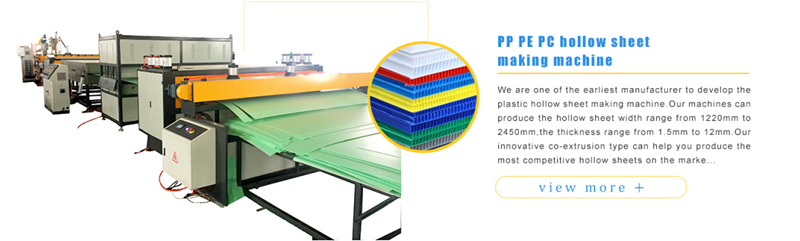

Tongsan PP Plastic hollow corrugated sheet board extruder making machine

- US $135000.00

1 - 1 piece

group namePP PE PC Plastic Hollow Sheet Extrusion Machine

-

Min Order1 piece

brand nameQingdao Tongsan

modelTS1400/TS1860/TS2300/TS2600

payment methodL/C, Western Union, MoneyGram, T/T, Paypal

-

update timeThu, 14 Nov 2019 11:42:22 GMT

Paramtents

Sheet width 1220mm-2450mm

Sheet thickness 2mm-12mm

production speed 0.3m/min-6m/min

Extruder type single screw extruder

Extruder Model SJ100 SJ120

Motor power 75kw/90kw/110kw

Capacity 170kg/h-350kg/h

Warranty One year

Service Engineer oversee service

Packging & Delivery

Size500cm x 500cm x 500cm

Weight22000.00kg / piece

Min Order1 piece

Briefing

Detailed

Qingdao Tongsan Plastic Machinery co.,;td have been develop the PP hollow corrugated sheet making machine since 2015,now we have the machines for the PP hollow grid plate width from 1220mm to 2450mm and thickness from 1.5mm to 12mm.

We have different model production line,such as the 1400 type PP hollow sheet extruder machine,1860 type PP corrugated sheet production line,2300 type PP hollow corrugated board making machine,2600type plastic hollow grid panel making machine,and for each model.

we design the co-extrusion type for customer choose.The co-extruder type can use 20%-60% fillermatch for reduce the cost,so our customer can product the cost competitiveness sheet with goog quality.

Our machine have the advantage of high output,easy operation,high precision,good products with smooth surface straight rib.

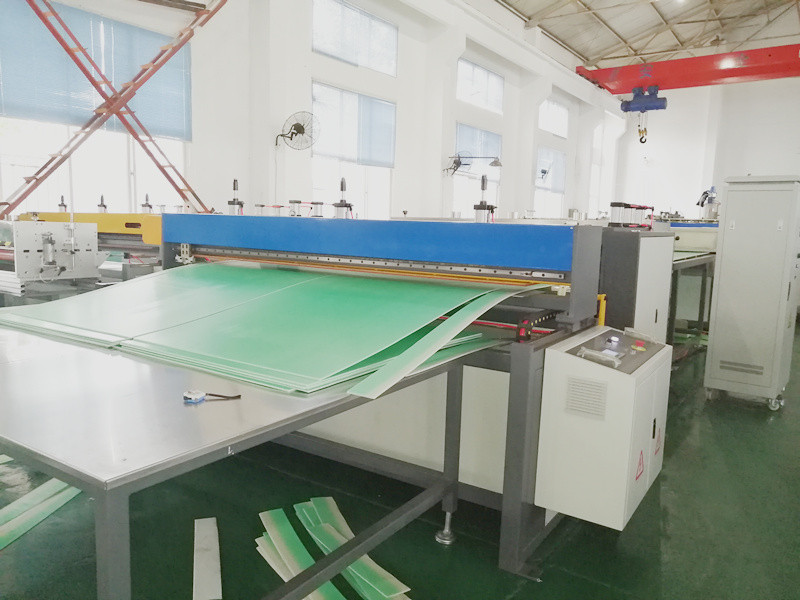

Special screw with 60% filler masterbatch,high-quality mold with large thickness adjustment, and synergistic structural design to ensure efficient production of high quality sheet.

We have PP hollow corrugated sheet making machine in stock and can running machine for free when customer visit our factory

Model | Max.Sheet width | Sheet thickness | Extruder Model | Main Motor Power |

TS-1400 | 1250mm | 2-6,8-12mm | 100/36 | 55-75kw |

TS-1860 |

1700mm |

2-6,8-12mm |

120/6 |

75-90kw |

TS-2300 | 2150mm | 2-6,8-12mm | 120/36 | 90-110kw |

TS-2600 |

2450mm |

2-6,8-12mm |

120/36 |

90-110kw |

TS-1400(co) | 1250mm | 2-6,8-12mm | 100/36+65/36 | 75kw+37kw |

TS-1860(co) |

1700mm |

2-6,8-12mm |

120/36+65/36 |

90kw+37kw |

TS-2300(co) | 2150mm | 2-6,8-12mm | 120/36+80/36 | 110kw+37kw |

TS-2600(co) | 2450mm | 2-6,8-12mm | 120/36+80/36 | 110kw+37kw |

The specially designed screw and the advanced controlling system ensure excellent plasticization,high output and stable extruding.We have the co-extrusion type to use the recycled plastic to reduce the cost with high quality products.

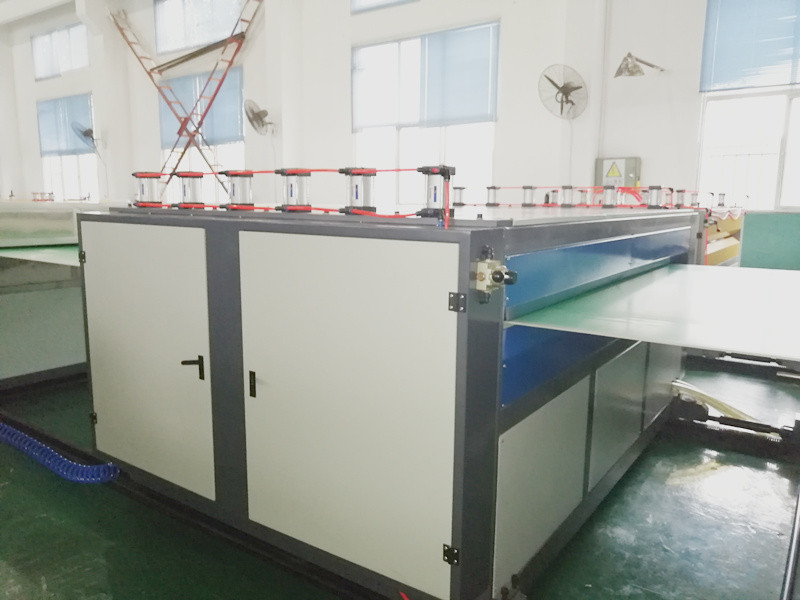

Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips,and also differential action of up-down piece guarantee even thickness of the plate.

There are two tractor.The first one is high power,high reduction ratio,multi-roller type,well low-speed operation,high traction and is able to draw the plate up from the calibrating table evenly and synchronal.The second one is designed to remove stress,and in addition it is equipped with edge-cutting device to ensure the valid width and smooth cut of the edges.

The advanced large area conductive heating mode can effectively remove the stress of plate and further improve planeness of the plate.

Accurate instant length-fixed cutting and automatic up-down discharging system combined with alloy steel sharp blade realize high quality of cutting.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow