Hot sale PP corrugated hollow sheet gift boxes making machine price

group namePP PE PC Plastic Hollow Sheet Extrusion Machine

-

Min Order1 piece

brand nameQingdao Tongsan

modelSJ120/36

payment methodL/C, Western Union, MoneyGram, T/T, Paypal

-

update timeFri, 22 Nov 2019 12:52:40 GMT

Paramtents

Sheet width 1700mm

Sheet thickness 2-6mm,7-12mm

Main extruder SJ120/36

Main motor power 90kw

Extruder capacity 230-260kg/h

Production speed 0.3-6m/min

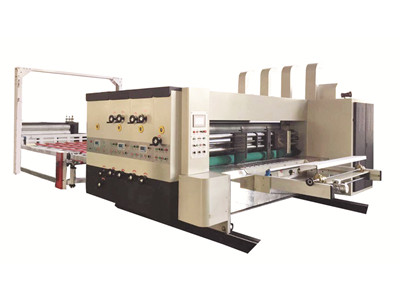

Boxes making machine Die cutting machine

Boxes making machine Printing machine

Boxes making machine Welding machine

Packging & Delivery

Size500cm x 500cm x 500cm

Weight260000.00kg / piece

Min Order1 piece

Briefing

Detailed

1, according to the product width: can be divided into ZKB1400 type, ZKB1860 type, ZKB2300 type, ZKB2600 type unit

2, according to the thickness of the product: can be matched with 2-6mm, 6-12mm, 12-18mm special hollow grid plate mold

3, according to product structure: can be divided into single-layer board, double-layer co-extruded board, multi-layer co-extruded board

4, according to the shape of the product: can be divided into basic type - I type; special type - S type, V type, X type, rice type, etc.

5. Use plastic raw materials according to products: high-speed and high-efficiency plastic extruder that can be used for PP, PE, PC and other raw materials.

No. |

Machine Part List |

Quantity |

1 | High speed and high efficiency single screw plastic extruder | One set |

2 | drying hopper + automatic feeding machine | one set |

3 | non-stop hydraulic quick change screen | one set |

4 |

hollow grid plate mold |

one set |

5 | vacuum setting device | one set |

6 | the first traction mechanism | one set |

7 | Hot drying setting device | one set |

8 |

Cold air setting device |

one set |

9 | the second traction mechanism | one set |

10 | sheet cutting mechanism | one set |

11 | the stacking platform | one set |

12 |

PLC computer control system |

one set |

13 | Optional | automatic screw feeder + forced feed hopper |

chiller + cooling tower | ||

edge material recycling machine | ||

crusher |

PP hollow corrugated sheet introduction: Tongsan hollow board waterproof plastic carton is a new type of packaging material, which has been carefully processed. The hollow board waterproof plastic carton product is waterproof, moisture-proof and corrosion-resistant, has large bearing capacity, is non-toxic and tasteless, and can be recycled and recycled. It is more environmentally friendly and practical than the cardboard structure turnover box product.

PP hollow corrugated sheet color: black, white, blue, green, red, yellow, purple; rich in color, according to the customer's product personality requirements, custom plate color and plate surface printing, painting, stickers and so on.

PP hollow corrugated sheet features: rich color, convenient stacking, waterproof, anti-corrosion, light weight, impact resistance, anti-aging, anti-stretching, anti-compression and other properties, large carrying capacity, high turnover times, suitable for heavy-duty product packaging, hollow board material can be It is fully recycled and reused, environmentally friendly and in line with ROSH standards.

PP hollow corrugated sheet applicable industries: in the automotive industry, electronics industry, fruit industry, food industry, tobacco industry, logistics industry, household industry, agricultural and sideline products, lighting gifts and other industries in the sales, transportation, turnover process. .

PP hollow corruagetd sheet specifications: thickness 2mm-12mm,width1220mm-2800mm

Because the binding machine is a machine that fixes paper, plastic, leather, etc. with staples or hot melt adhesives. Therefore, the whole operation process can be divided into several steps such as punching, pipe cutting, pipe laying, and riveting.

According to the degree of automation of the binding machine operation process can be divided into: manual binding machine, semi-automatic binding machine, electric pressure riveting (automatic) binding machine, fully automatic binding machine.

The chillers are also called: chillers, refrigeration units, chillers, cooling equipment, etc. Because of the wide range of uses in various industries, the requirements for chillers are also different. Its working principle is a versatile machine that removes liquid vapor through a compression or heat absorption refrigeration cycle.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow