2300mm plastic PC hollow corrugated sheet making machine production line price

group namePP PE PC Plastic Hollow Sheet Extrusion Machine

-

Min Order1 piece

brand nameQingdao Tongsan

modelSJ130/36

payment methodL/C, Western Union, MoneyGram, T/T, Paypal

-

update timeFri, 22 Nov 2019 12:50:53 GMT

Paramtents

Sheet width 2100mm

Sheet thickness 4-6mm,8-10mm

Main extruder SJ130/36

Main motor power 250kw

Extruder capacity 400kg/h

Co-extruder SJ45

Hydraulic screen changer 2 sets

Melt pump 1 set

Packging & Delivery

Size500cm x 500cm x 500cm

Weight260000.00kg / piece

Min Order1 piece

Briefing

Detailed

The high-speed and high-efficiency PC hollow corrugated sheet making machine production line series developed by Qingdao Tongsan Plastic Machinery Co., Ltd. and its special molds are advanced in technology, wide in applicability and stable in performance, depending on the width, thickness, hierarchical structure, hollow shape and plastic materials used. Have the following categories:

1, according to the product width: can be divided into ZKB1400 type, ZKB1860 type, ZKB2300 type, ZKB2600 type unit

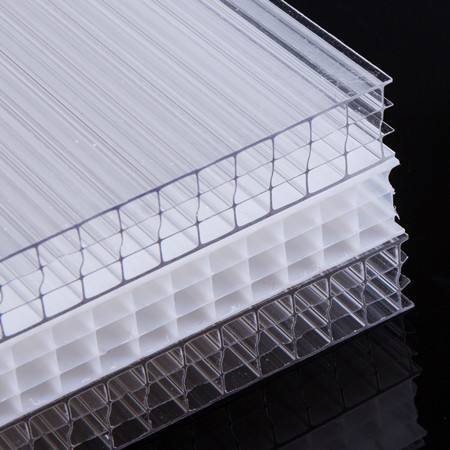

2, according to the thickness of the product: can be matched with 2-6mm, 6-12mm, 12-18mm special hollow grid plate mold

3, according to product structure: can be divided into single-layer board, double-layer co-extruded board, multi-layer co-extruded board

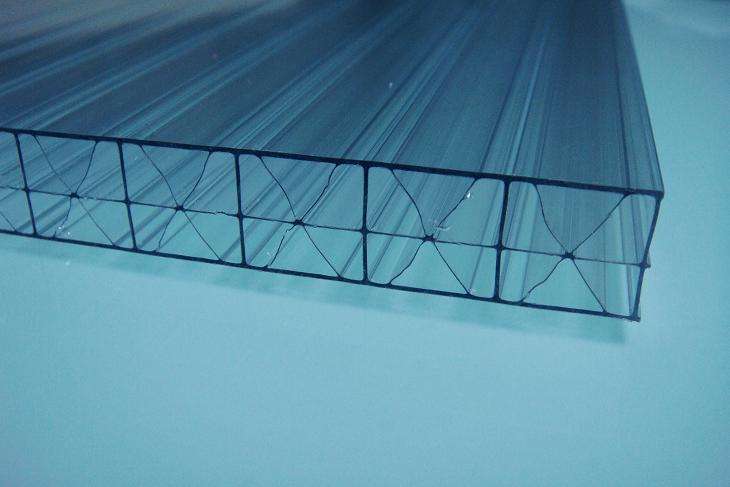

4, according to the shape of the product: can be divided into basic type - I type; special type - S type, V type, X type, rice type, etc.

5. Use plastic raw materials according to products: high-speed and high-efficiency plastic extruder that can be used for PP, PE, PC and other raw materials.

No. |

Machine Part List |

Quantity |

1 | High speed and high efficiency single screw plastic extruder | One set |

2 | Co-extrusion single screw extruder | one set |

3 | drying hopper + automatic feeding machine | one set |

4 | non-stop hydraulic quick change screen | one set |

5 |

hollow grid plate mold |

one set |

6 | vacuum setting device | one set |

7 | the first traction mechanism | one set |

8 | Hot drying setting device | one set |

9 |

Cold air setting device |

one set |

10 | the second traction mechanism | one set |

11 | sheet cutting mechanism | one set |

12 | the stacking platform | one set |

13 |

PLC computer control system |

one set |

14 | Optional | automatic screw feeder + forced feed hopper |

chiller + cooling tower | ||

edge material recycling machine | ||

crusher |

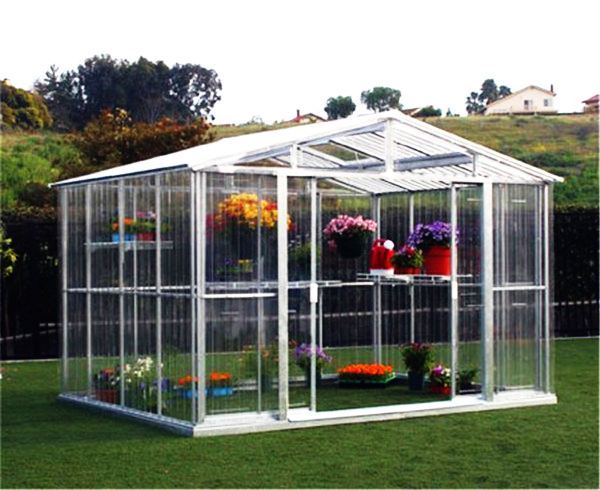

Suitable for gardens, amusement parks, exotic decorations and rest places;

Applicable to the interior and exterior decoration of commercial buildings, the curtain wall of modern urban buildings;

Applicable to aviation transparent containers, motorcycle front windshields, airplanes, trains, ships, automobiles, motorboats, submarines and glass military and police shields;

Applicable to the layout of telephone booths, advertising signs, light box advertisements, and exhibitions;

Applicable to instruments, instruments, high and low voltage switchgear panels and military industry;

Applicable to high-grade interior decoration materials such as walls, ceilings and screens;

Suitable for highway and urban elevated road noise barriers;

Applicable to agricultural greenhouses and breeding greenhouses;

Suitable for modern ecological restaurant ceilings;

Applicable to bicycle sheds, balcony shade canopies and roof rest sheds in all units or communities;

Suitable for lighting ceilings in office buildings, department stores, hotels, villas, schools, hospitals, stadiums, entertainment centers and public facilities.

By the end of the 1970s, PC solar panels were gradually used in the civilian sector and were widely used.

Construction industry: building lighting roofs, curtain walls, doors and windows, partitions, passages, canopies, garages, bus shelters, pedestrian crossings, etc. for industrial, civil and public buildings.

Agriculture: vegetables, flowers, fruit trees, breeding, and other horticultural industries, agricultural greenhouses, breeding greenhouses, etc.

Sports: football, basketball, volleyball, tennis, ice hockey, golf, swimming, four seasons fishing and other venues, lighting, transparent partitions and a variety of sports and rides.

Wave Sunshine Board - Greenhouse

Wave Sunshine Board - Greenhouse

Urban construction: sound insulation barriers for expressways, expressways, elevated roads and overpasses.

Advertising industry: light boxes, signs, display cards, etc.

Business: high-end interior decoration, shelves, booths, and various indoor items.

Transportation: Windshield, canopy, hatch, etc. of the aircraft.

Security: bulletproof glass, masks, helmets, shields, jewelry counters, protective cover for articles and articles.

Industry: a variety of instrumentation cover, instrument panel series.

1, DELIVERY CONDITIONS:

1.1 DELIVERY CONDITION: FOB QINGDAO PORT.

1.2 DELIVERY TERM: WITHIN 60-90 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

4.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER SHOULD ARRANGE FOR SUPERVISION OF LOADING.

2,WARRANTY TERMS:

2.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

2.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

2.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

3,INSPECTION:

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER’S FACTORY. THE BUYER SHOULD COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK.

4,INSTALLATION AND EQUIPMENT COMMISSIONING:

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER’S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE, AND THE BUYER SHOULD UNDERTAKE THE WHOLE FOOD/PLACE AND ROUND TICKETS (AIRPLANE, FOOD, HOTEL, AND SO ON), AND PAY SALARY TO ENGINEER FOR 100 USD/DAY/ENGINEER.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow