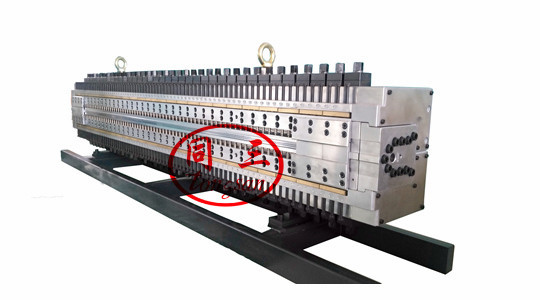

PP hollow corrugated sheet corrugated box manufacturing machine mold

group namePP PE PC Plastic Hollow Sheet Extrusion Machine

-

Min Order1 piece

brand nameQingdao Tongsan

model1400 TYPE

payment methodT/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

-

update timeFri, 22 Nov 2019 12:48:47 GMT

Paramtents

Mold valid width 1400mm

sheed valid width 1250mm

Adjust thickness 2-6mm,7-12mm

Mold material Alloy steel forging

Heating type Inner heating

Heating Stainless steel heating roller

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips,and also differential action of up-down piece guarantee even thickness of the plate.

Model | 1400 |

Length of mold mouth | 1400,product width=1250mm |

Material | Alloy steel forging |

Heating type | Inner heating |

Heating | Stainless steel heating roller |

Heating power | 37kw |

Control of air | Air flow controller |

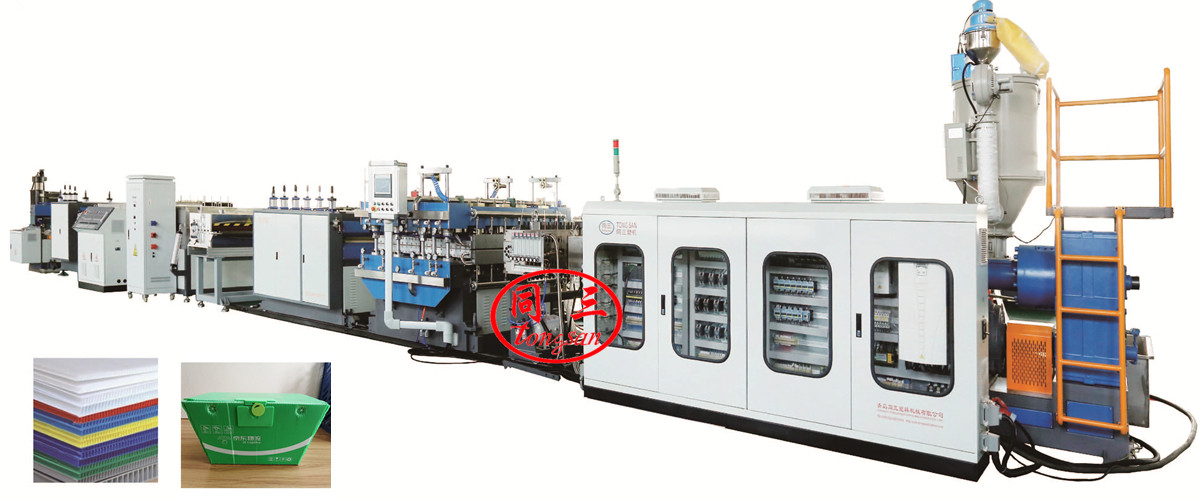

Our hollow corrugated sheet making machine can produce the sheet with the width of 1220-2450mm and thickness of 1.5mm-12mm.The details of the production line:

Model | Sheet Width | Sheet Thickness | Extruder Model | Motor Power |

TS-1400 | 1250mm | 2-6, 8-12mm | 100/36 | 55-75kw |

TS-1860 | 1700mm | 2-6, 8-12mm | 120/6 | 75-90kw |

TS-2300 | 2150mm | 2-6, 8-12mm | 120/36 | 90-110kw |

TS-2600 | 2450mm | 2-6, 8-12mm | 120/36 | 90-110kw |

TS-1400(co) | 1250mm | 2-6, 8-12mm | 100/36+65/36 | 75kw+37kw |

TS-1860(co) | 1700mm | 2-6, 8-12mm | 120/6+65/36 | 90kw+37kw |

TS-2300(co) | 2150mm | 2-6, 8-12mm | 120/36+80/36 | 110kw+37kw |

TS-2600(co) | 2460mm | 2-6, 8-12mm | 120/36 +80/36 | 110+37kw |

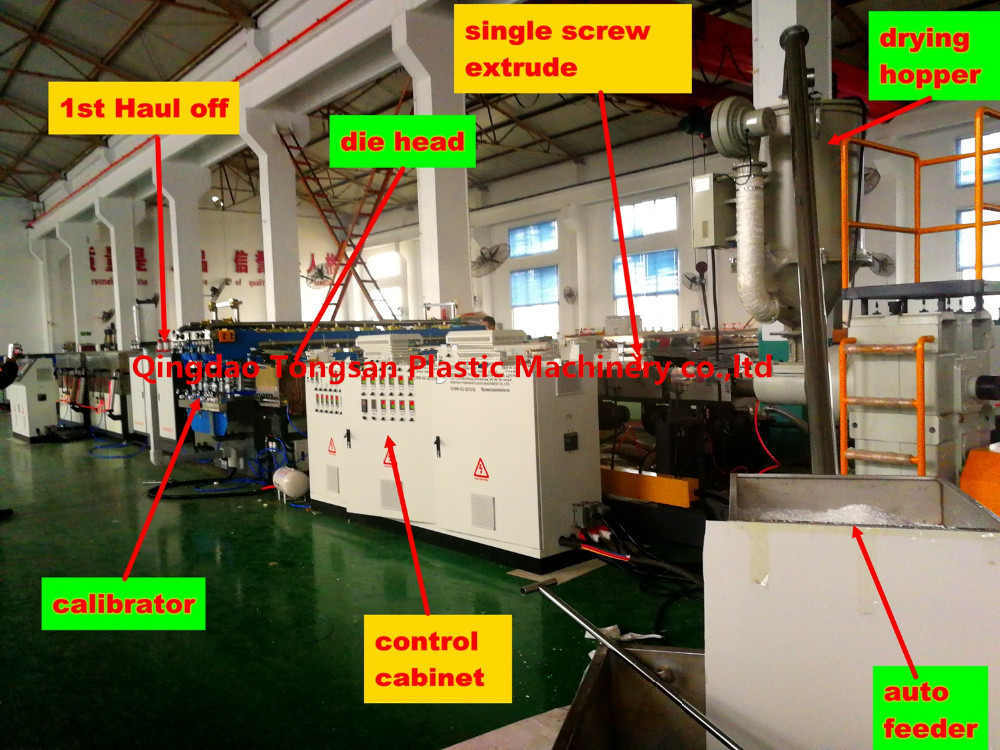

1,Extruder

The specially designed screw and the advanced controlling system ensure excellent plasticization,high output and stable extruding.We have the co-extrusion type to use the recycled plastic to reduce the cost with high quality products.

2,Screen changer

Quick screen changer of hydraulic system ensure the continuously working of screen changing.Double position combined with special sealing structure guarantee stable operation of screen changer.

3,Mould

Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips,and also differential action of up-down piece guarantee even thickness of the plate.

4,Vacuum calibrating table

Heating exchanging and cooling system of quick speed in calibrating system alternate effectively and ordinally with vacuum system,which ensure calibrating precision.Vacuum system composes two independent subsystems and each is equipped with several fixed circulating vacuum lines of three-point type.Meanwhile,each line carries vacuum regulating system and vacuum display system that realize even and stable vacuum degree of plate surface.

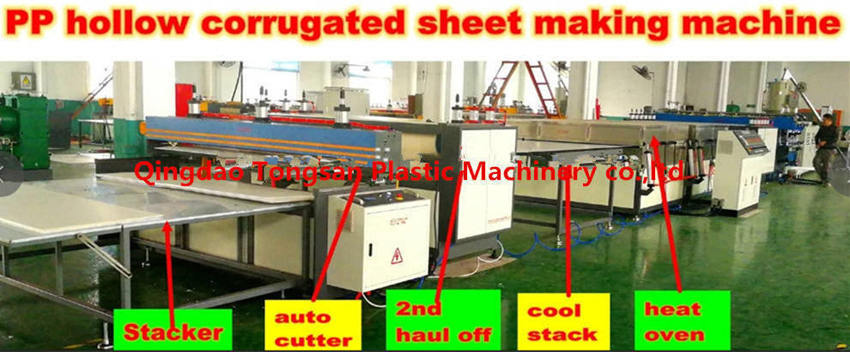

5,Tractor

There are two tractor.The first one is high power,high reduction ratio,multi-roller type,well low-speed operation,high traction and is able to draw the plate up from the calibrating table evenly and synchronal.The second one is designed to remove stress,and in addition it is equipped with edge-cutting device to ensure the valid width and smooth cut of the edges.

6,Stress remover

The advanced large area conductive heating mode can effectively remove the stress of plate and further improve planeness of the plate.

7,Corona machiner

In order to improve the surface tension of the hollow sheet surface, and thereby improve the printing ink fastness, the hollow corrugated sheet surface will under corona treatment, so that the surface produces micro-concave dense holes, plastic surface roughening, increase the surface activity.

8,Cutting machine

Accurate instant length-fixed cutting and automatic up-down discharging system combined with alloy steel sharp blade realize high quality of cutting.Item | PP packing box making Machine | Note |

01 | Material Mixing machine | For mixing material, such as chemicals, color masterbatch, filling masterbatch, recycle material |

02 | PP hollow corrugated sheet extrusion line | For makeing Pp hollow corrugated sheet for required width and thickness. width: 1200-2700mm thickness: 2-12mm |

03 | PP hollow sheet die cutting machine | For cutting the Pp sheet into required shape for folding box |

04 | PP hollow sheet printing machine | for printing logo and designs on the Packing box, there is different printing machine, such as single color printer, double color printer, four color printer. |

05 | PP hollow sheet welding machine PP hollow sheet bookbinding machine | For folding the Pp hollow sheet into required box shape, welding machine and bookbinding machine both can work for it |

Our service

1,We have all series plastic hollow corrugated sheet making machine in production,warmly welcome to visit our factory for machine running.The machine running is the best prove of the machines' quality ,the good quality machine is the granulating for the high effective production.

2,We can testing the machine according customer's formula.One is the customer can inspect the quality of our machine,another is the customer can check the quality of the products,so it is easy to calculate the cost of the sheet and the production capacity of our machines.So it's easy to calculate the investment pay back and increase the feasibility of the project.

3,We are professional for the auxiliary machine for sheet raw material making and plastic boxes making.We can provide the plastic filler masterbatch granulating making machine,the wast sheet crusher,the raw material mixing machine,the die cutting machine,the corona treatment machine,the sheet printing machine,the welding / bookbind machine .

4,Our engineer oversee installation and debugging ,our engineer with rich experience and will teach customer's worker about the operating one by one.And we provide long life time technical support.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow