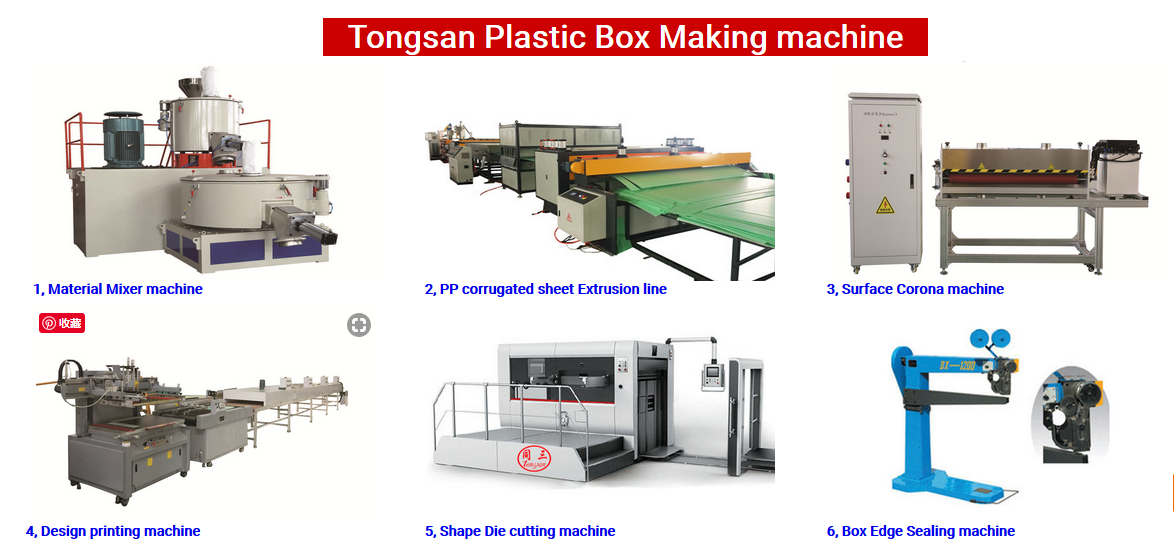

Silk screen PP hollow corrugated sheet making machine

- US $7500.00

1 - 1 piece

group namePlastic hollow sheet box making auxiliary machine

-

Min Order1 piece

brand nameQingdao Tongsan

payment methodL/C, MoneyGram, T/T, Paypal

-

update timeThu, 24 Sep 2020 13:18:11 GMT

Paramtents

Equipment model JY-7010B machine

Working platform area(mm) 800*1100

Printing speed(pcs/h) 500-1200

Gas consumption(0.6Mpa)(L/pcs) 13/PCS

Packging & Delivery

Min Order1 piece

Briefing

Minimum screen setup (mm) 800*950

Printing speed(pcs/h) 500-1200

Detailed

Plane silk screen printing machine widely used in the packaging industry(e.g. Cigarette box packaging, wine box packaging, gift box packaging, etc.Card printing), trademark, calendar, oil painting, computer keyboard,Printing of New Year pictures, transfer paper, adhesive and credit CARDS;Also suitable for electronic industry related printing.

Equipment model | JY-7010B |

Working platform area(mm) | 800*1100 |

Maximum printing area(mm) | 700*1000 |

Largest screen setup (mm) | 950*1200 |

Minimum screen setup (mm) | 800*950 |

Load bearing thickness(mm) | 0-20.0-50 |

Printing speed(pcs/h) | 500-1200 |

Work pressure(Mpa) | 0.4-0.6 |

Gas consumption(0.6Mpa)(L/pcs) | 13/PCS |

Power (kw) | 2.3 |

Minimum height of workbench plate (relative ground)(mm) | 820 |

Shape size (l*w*h)(mm) | 1900*1450*1280 |

Weight (kg) | 480 |

Nominal voltage(v/Hz) | 220V50HZ / 380V |

Performance advantage

1) oblique arm structure.

2) the lifting and lifting of the printing arm -- it adopts the frequency conversion system and the connected reducer, and the speed is adjustable.

3) drag of the printing knife -- variable frequency drag system drives the printing tool holder and synchronous belt drive.

4) separate adjustment and control of printing/ink return speed, convenient travel adjustment.

5) stainless steel bond printing platform, decorated with fine adsorption holes for less than 30 minutes 1.0~1.5, strong vacuum automatic adsorption.

6) the horizontal and vertical direction of the printing platform is set with accurate adjustment, and the multi-color matching is accurate.

7) pneumatic disconnecting device, effectively preventing large area of printing paper and printing pattern paste.

8) 2 sets /4 cylinders ensure the balance and stability of printing and ink return pressure, and the ink scraper and ink return knife automatically switch.

9) the Angle of scraping and ink return can be adjusted, and the operation is flexible and convenient.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow