SHJ70 parallel double screw extruder PP filling masterbatch making machine

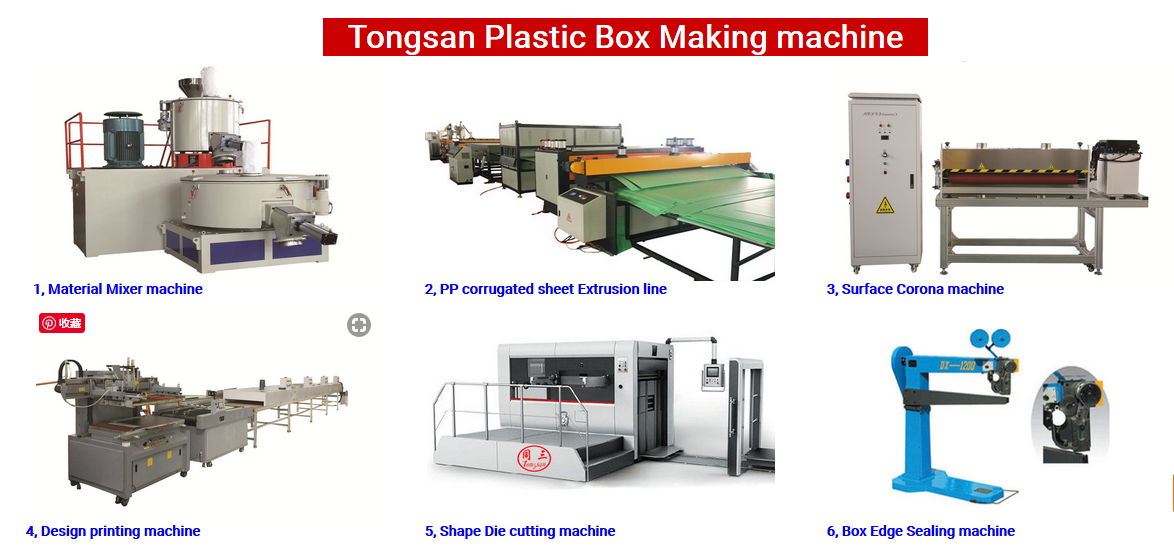

group namePlastic hollow sheet box making auxiliary machine

-

Min Order1 piece

brand nameQingdao Tongsan

payment methodL/C, Western Union, MoneyGram, T/T, Paypal

-

update timeThu, 24 Sep 2020 13:18:43 GMT

Paramtents

Model SHJ70 parallel double screw extruder

Capacity 300-400kg/h

Motor power 132kw

Packging & Delivery

Min Order1 piece

Briefing

Detailed

SHJ70 parallel double screw extruder PP filling masterbatch making machine

Material and Formula for reference

PP resin | 20kgs |

CaCo3 | 100 kgs |

Coupling agent | 1.5 kgs |

Stearic acid | 2 kgs |

Paraffin wax | 2.6 kgs |

Titai white | 2.6 kgs |

Item | Machine | Quantity |

01 | SHR300A mixing machine | 1 set |

02 | SHJ70 parallel double screw extruder | 1 set |

03 | Hydraulic screen changer | 1 set |

04 | Granulating die head | 1 set |

05 | Cooling tank | 1 set |

06 | Water brace granulating auxiliary machine | 1 set |

07 | Product conveying system | 1 set |

08 | Electricity control system | 1 set |

SHR300A mixing machine

Mixing type: hot mixing only |

Lid material : Casting AL |

High-speed thermal mixer volume:300 L |

Thermal mixing valid volume: 225L |

Number of stirring blade: 3 PIECES |

Material of stirring blade: 3Cr13Ni9Ti |

SHJ-70 syntropy double screw extruder

Length diameter ratio | 36:1 |

Output rotation speed | 400RPM |

Center distance | 52mm |

Transmission box shell | Cast iron, sound proof optimization combinational design |

Gear wheel | 6 class precision, high speed heavy load hard teeth surface, gear wheel shaft material is 20CrNi 2MoA, HRC58-62 |

Hydraulic screen changer:

Hydraulic screen changer:

Non stop, Non leaking material

Granulating die head:

Granulating die head:

The numbers of granulating strips are designed for 13-16PCS

Convey belt cooling system

Convey belt length | 20 meters |

Convey belt width | 400mm |

Motor power | 1.5 KW |

Belt material | High temperature resistance belt |

Cooling blower | 350W*10 sets |

Granulating cutting machine

Model | LQ-300 granulating machine |

Power | 7.5kw, 380V/50Hz, slip frequency speed regulator |

Max capacity | 300-350kg/h |

Granulating grain quantity | 17pcs |

Traction speed | 0-90RPM |

Cutting blade size | Ø200mm*200mm |

Material convey | By stainless steel pipe with screw |

Bin material | Stainless steel |

Material tank material | Stainless steel |

Tank volume | 1CBM |

Tank transportation | With moving wheels |

inverter | ABB brand |

Motor | Siemens brand |

Temperature control | Omron brand |

Contractor | Schneider brand |

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow