spiral corrugated making line manufactuer in China with best quality

group namePP PE PPR Pipe Machine

-

Min Order1 piece

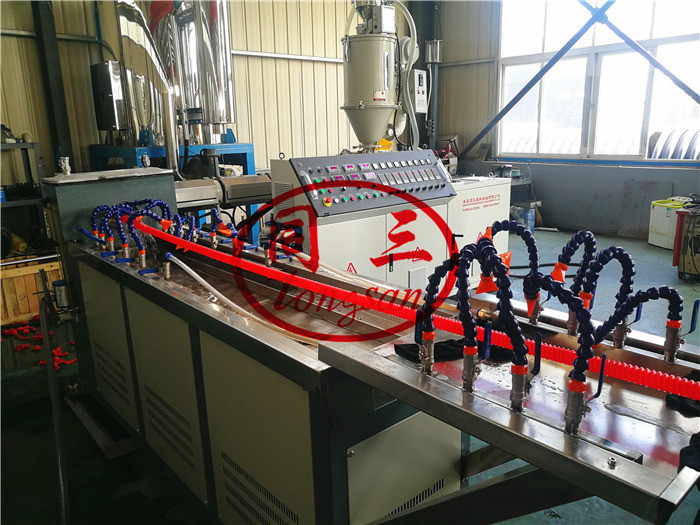

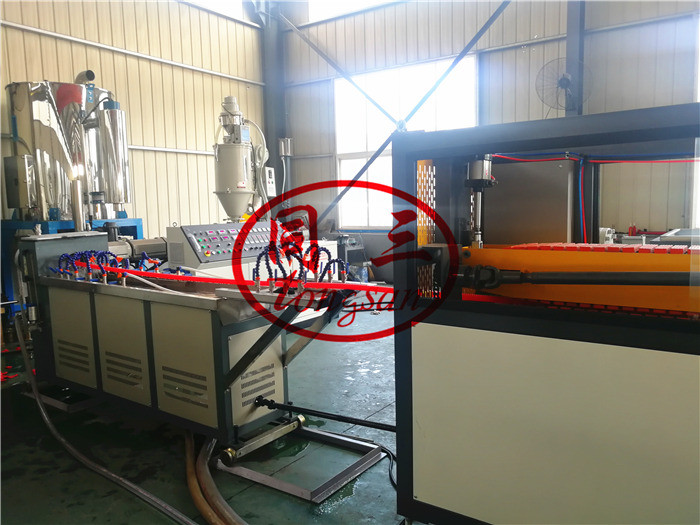

brand nametongsan

modelSJ65/30

payment methodL/C, D/A, D/P, Western Union

-

update timeTue, 08 Dec 2020 14:11:38 GMT

Paramtents

pipe diameter 25-200mm

speed 1-2m/min

pipe application electricity,telecome....

material HDPE

Packging & Delivery

Size150cm x 30cm x 40cm

Weight5000.00kg / piece

Min Order1 piece

Briefing

1-2m/min speed

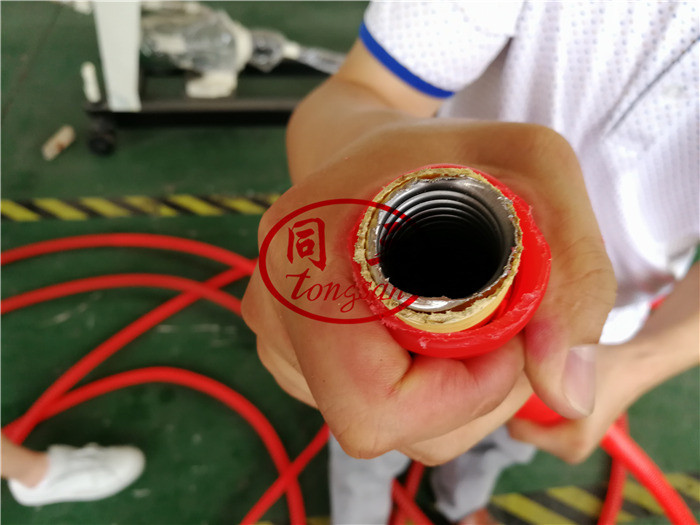

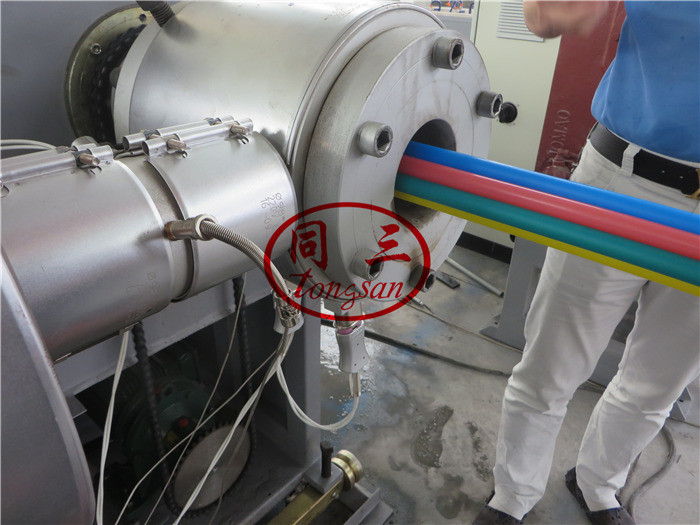

can feed steel/plastic pipe inside

pipe used in electricity, telecom,post activities...

Detailed

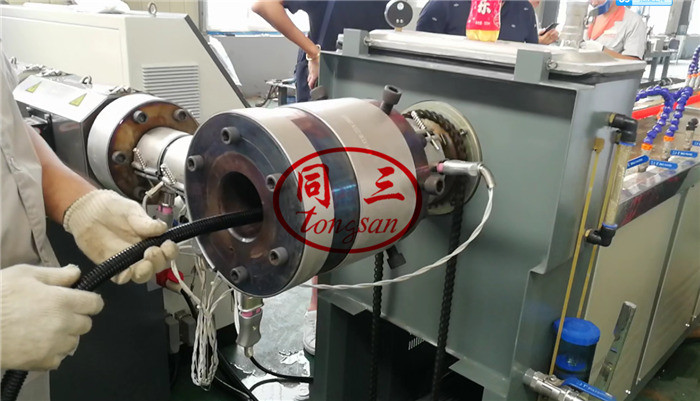

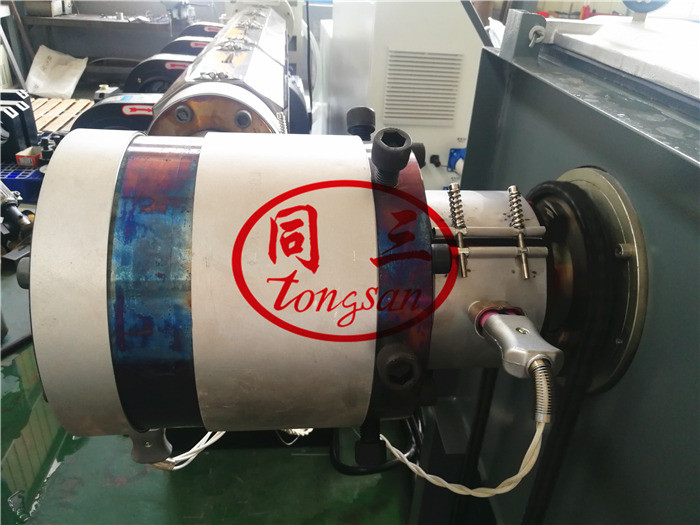

2. The pipe die head is designed in standard, and the reasonable flowing path ensures smoothness of the inside and outside walls of the pipe. The way of assembling the die head is designed according to the client’s requirement, which saves much room.

3. Both scientifically designed copper spiral sizing sheath and the powerful inhaling vacuum device contribute to high extrusion of the pipes.

4. The tank is made of stainless steel, and automatic controller is used to control the liquid level. The peculiar spraying nozzle brings about effective cooling and the motor ensures longitudinal movement and three-dimensional adjustment in terms of the directions of upward, downward, left and right.

5. The special sizing and cooling mode enable the production line to produce pipes whose diameter range is from 25mm to 200mm, at a speed of 1 to 2 meters per minute.

|

model

|

SJ65/30

|

SJ90/30

|

screw LD | 30:1 | 30:1 |

|

pipe diameter

|

25-100

|

75-200

|

|

production capacity

|

60-80kg/h

|

100-120kg/h

|

|

production speed

|

1-2m/min

|

1-2m/min

|

power | 37kw | 55kw |

You need a product

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram