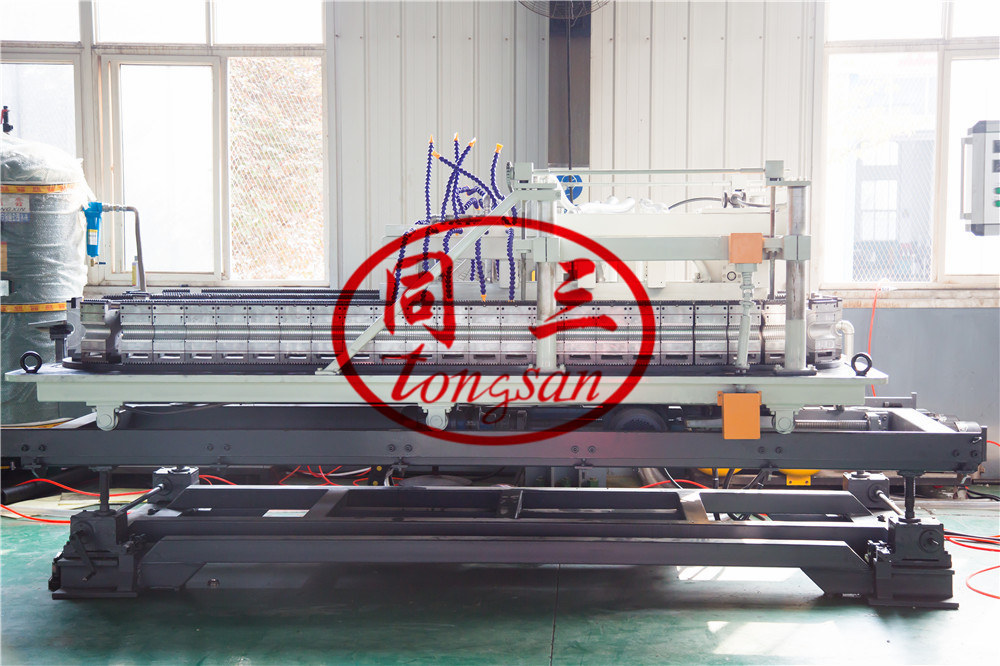

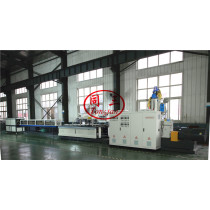

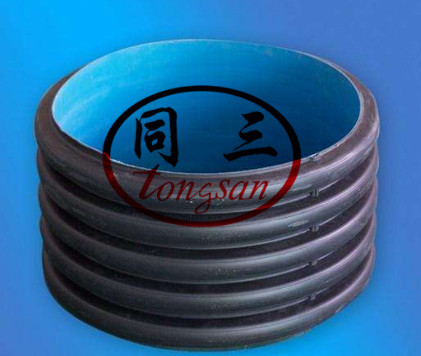

double wall corrugated hdpe pipe machine factory with best quality cost

group nameDouble Wall Corrugated Pipe Machine

-

Min Order1 piece

brand nametongsan

modelSJ90/30+SJ75/30

payment methodL/C, D/A, D/P, Western Union

-

update timeTue, 08 Dec 2020 14:13:01 GMT

Paramtents

mould material cast aluminum

mould pairs 48

speed 0.5-5m/min

machine model SJ90/30+SJ75/30

forming type air blowing and vacuum

machine type horizontal

production line length 25m

delivery time 60 days

port Qingdao China

Packging & Delivery

Size150cm x 30cm x 40cm

Weight20000.00kg / piece

Min Order1 piece

Briefing

sample machine in stock

7 designers

10 engineer available

make mould by our German CNC machine

Detailed

|

machine model

|

SBG250

|

SBG110

|

SBG160

|

PVC-SBG250 |

|

pipe diameter mm

|

75-250

|

40-110

|

50-160

|

75-250 |

|

extruder screw

|

single

|

single

|

single

|

double |

extruder model | SJ90/30+SJ75/30 | SJ65/33+SJ65/30 | SJ75/30+SJ65/30 | SJ65/132 |

mould block pairs | 48 | 72 | 72 | 48 |

mould block material | Aluminum | iron | iron | 48 |

1, we will provide not only machines but also raw material to produce final product

2, we will provide design for factory layout and electrical power accounting

3, we will provide the model selection and technicial parameters

When our corrugated pipe machine arrives to Customer's factory, we shall help customer to prepare the material,electricity and other running conditions.

then we will send our engineers to customer's factory for installation all the machines and running all the machines.

our engineer shall also teach customer's engineer how to operate machine.

After that if the customer's engineer has any problem in the cooperation, they can contact our service team to do online training.

You need a product

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram