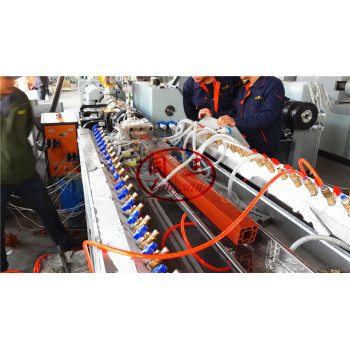

WPC Square Post Making Machine/ wpc column making machine/ wpc pavilion making machine

group namePP PE WPC Profile Machine

-

Min Order1 piece

brand nametongsan

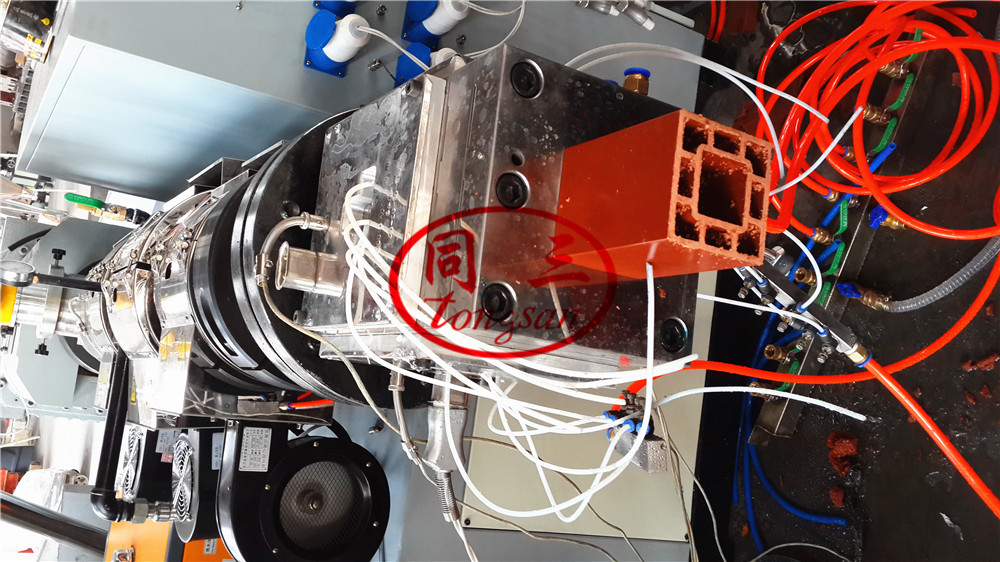

modelSJ65/132

payment methodL/C, Western Union, MoneyGram, T/T, Paypal, cash

-

update timeTue, 20 Oct 2020 15:17:16 GMT

Paramtents

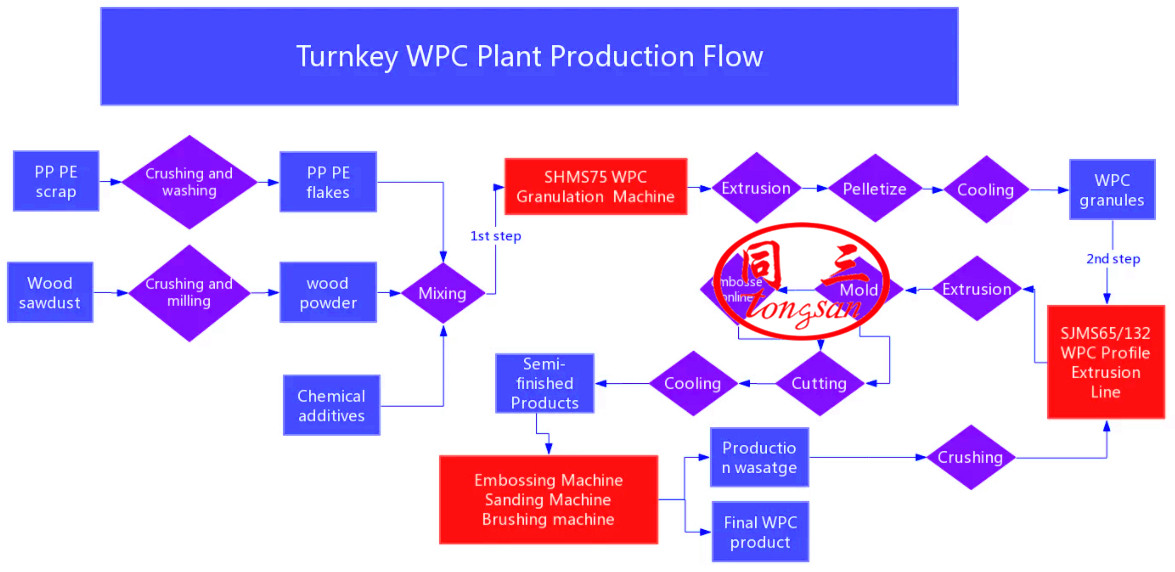

Plastic Material PE/PP Recycled Plastic Material

Wood Material Wood Sawdust/Rice Husk/Straw/Cotton Straw

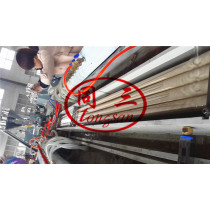

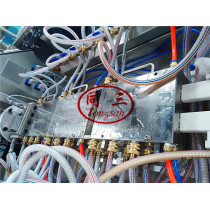

Processing Mixing, Granulating, Extrusion

Mchine WPC Outside Landscape Decking Post Fence Making Ma

Packging & Delivery

Min Order1 piece

Briefing

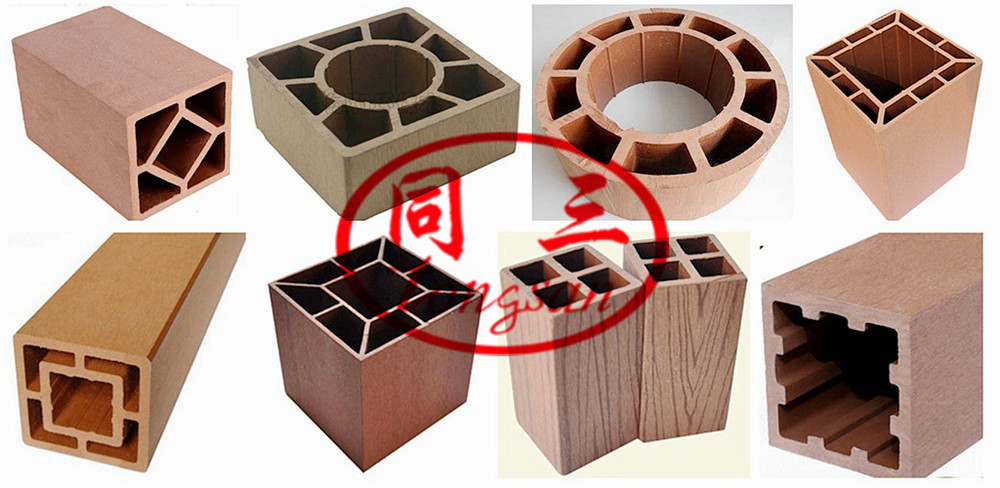

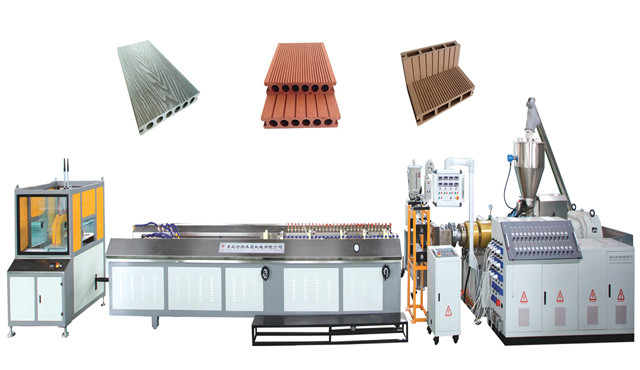

2. change mold can get different shape and size

3. recycled hdpe with wood

Detailed

|

size

|

60x60,70x70,90x90,100x100,120x120,150x150,200x200mm

|

|

material

|

30% recycled HDPE,67% wood fiber,3% chemical

|

finish | sanded,brushed,embossed,wood grain |

Range of Use | Garden, Lawn, Balcony, Corridor, Garage, Pool&SPA Surrounds, Boardwalk, Playground |

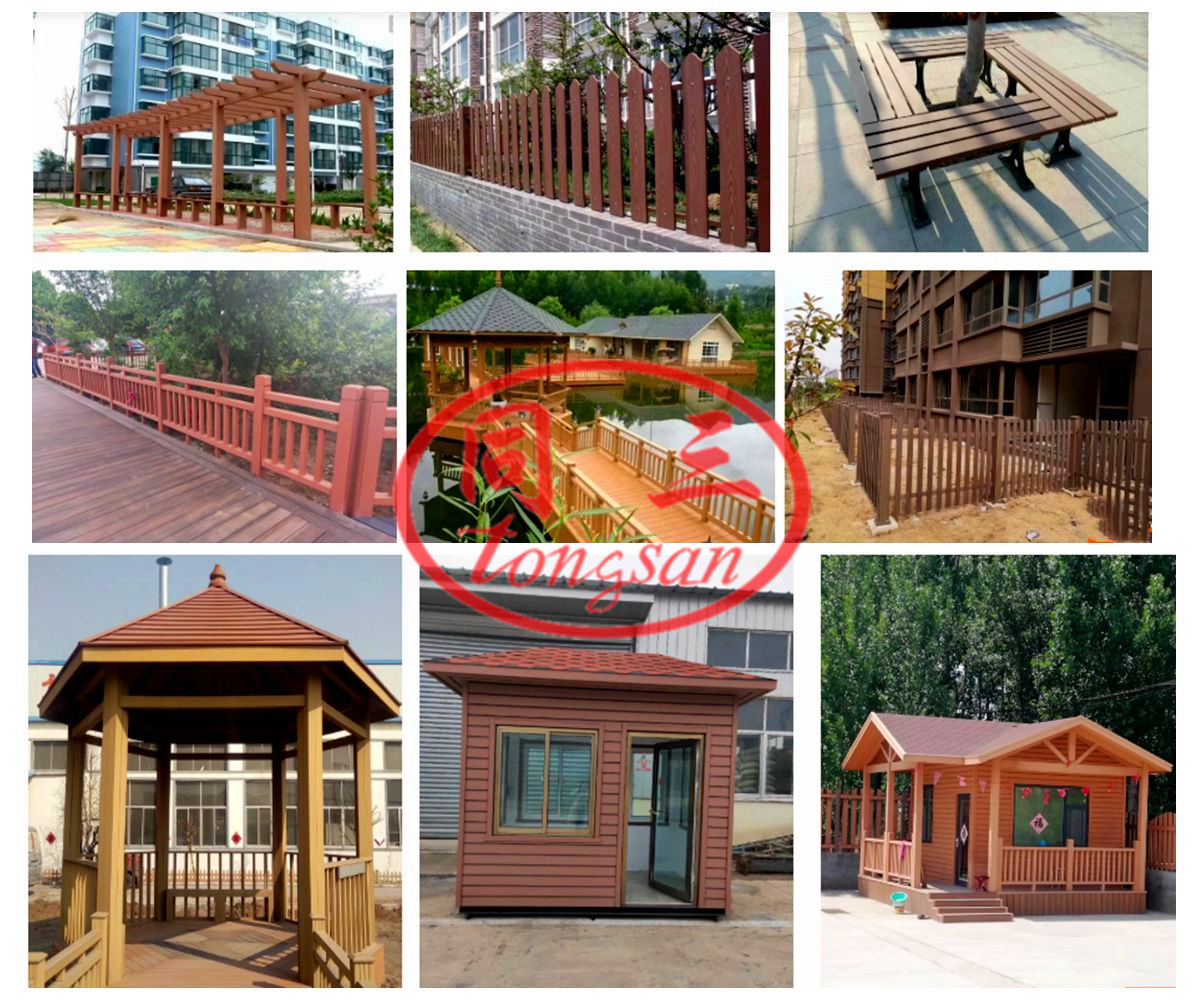

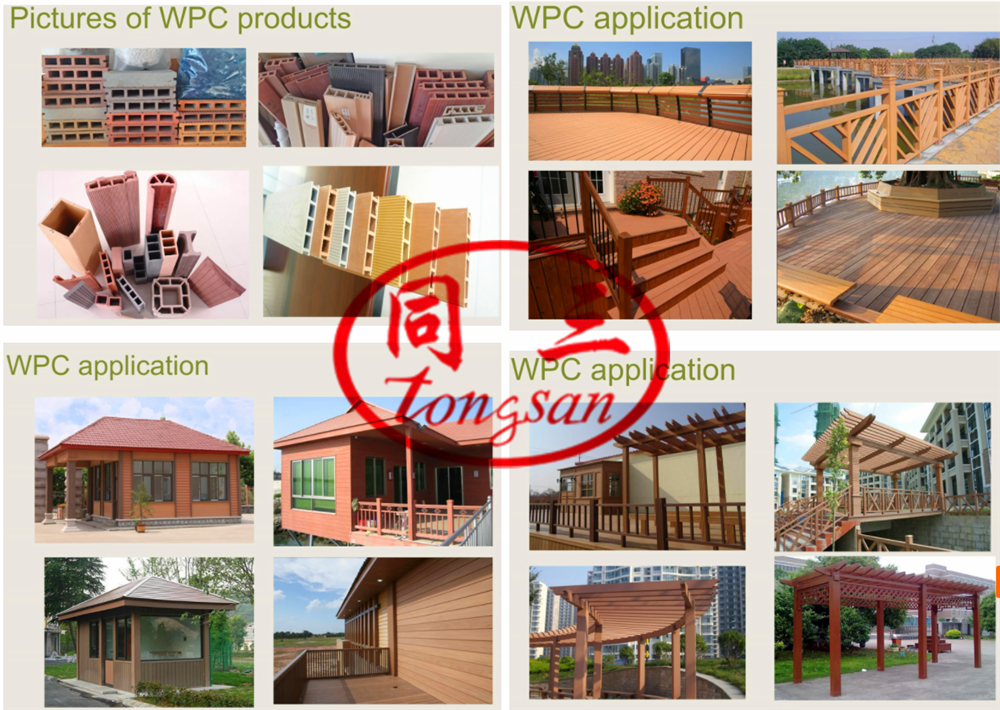

* Landscape Works: Outdoor Decking,Garden Pavilion,Fences,Handrails, Doors, Windows, Home Decor.

* Public Facilities: Flower Pots,Waste Bins, Lamppposts,Bus Station, Gazebo, Road Isolation Facilities,Highway Noise Barries.

* Entertainment Facilities:Style, Ceilings,Tables and Chairs.

* Decorative Facilities: Floor,Wall Decoration Panels, Interior Panels, Wall Panels, Stairs Board.

* Logistics Facilities: Tray, Pad Warehouse,Packaging Equipment.

Although wood-plastic composites are more expensive than pure wood, their relative high costs are gradually decreasing as manufacturers find more efficient processing methods. The use of recycled plastic in composite materials can further reduce costs. Even in the face of cost structure, many consumers are still willing to accept relatively high prices because of the advantages of these composite materials.

★ 1. Environment friendly:

Use of recycled materials (wood flour and plastic)

No need for preservative treatment

★ 2. No daily maintenance is required, and the service life is longer than that of wood. It does not absorb moisture, moisture, rot, and insects.

Does not crack, crack, or deform

Insensitive to cold and hot environments

★ 3. Polyolefin wood-plastic composites have good mechanical properties and can be widely used as load-bearing structural materials;

★ 4. 95% of the raw materials of polyolefin wood-plastic materials are recycled materials, so the cost is low, and the products can be recycled 100%.

★ 5, PVC wood-plastic composite materials improve the impact strength and reduce the specific gravity through micro-foaming, and truly imitate wood.

You need a product

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram