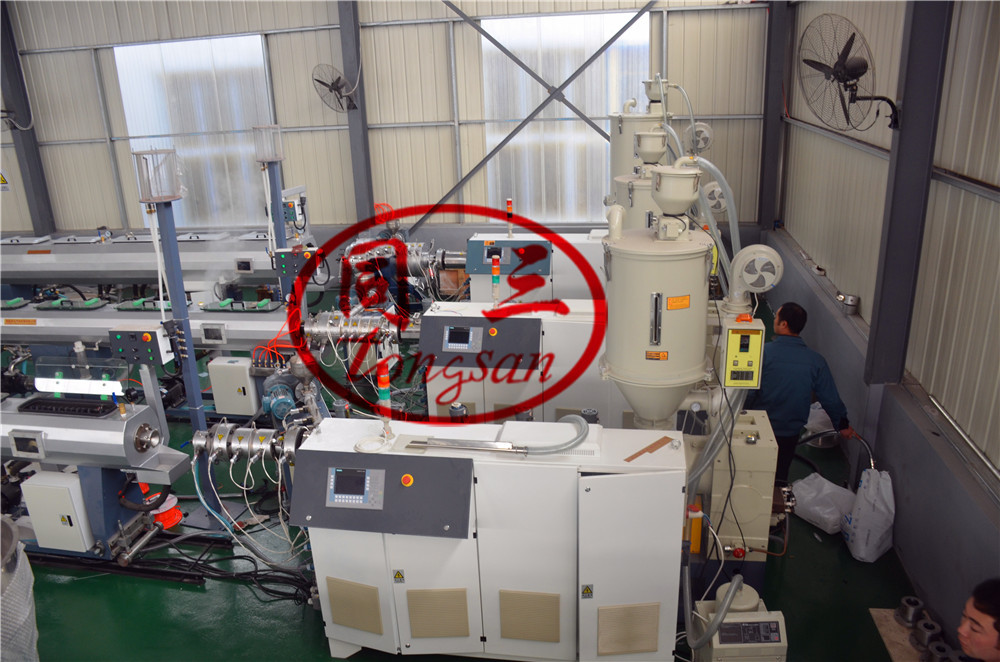

160-450mm High Speed HDPE Plastic Water Supplying And Gas Supplying Pipe Extrusion Line Machine

group namePP PE PPR Pipe Machine

-

Min Order1 piece

brand nametongsan

modelSJ50 SJ65 SJ70 SJ75 SJ90 SJ120

payment methodL/C, Western Union, MoneyGram, T/T, Paypal, cash

-

update timeFri, 04 Dec 2020 15:33:25 GMT

Paramtents

pipe diameter 315-630mm

machine type single screw

product tppe PP PE PPR Pipe

material HDPE LDPE PE

Packging & Delivery

Min Order1 piece

Briefing

equip three tanks for better cooling

Detailed

This production line adopts the most advanced technology of Europe,It is a new research achievement of ener- gy-saving production line,which is suitable for high speed extrusion of HDPE,PP and other polyolefin pipe.compared with corn- mon production line,the energy-saving effect reach on 35%,and the product efficiency increase more than 1 times, thus it is not only saving the cost of site and manpower, but also improving efficiency. This production line has nice appearance,higher auto- matical degree, production reliable and stable.

|

Extruder model |

Pipe diameter |

|

SJ50/30 |

16-25mm |

|

SJ65/33 |

16-63mm |

SJ75/30 | 20-110mm |

|

SJ75/33 |

75-250mm |

SJ90/33 | 160-450mm |

SJ120/33 | 315-630mm |

The main machine adopts screws specially used for polyethylene. Equipped with auto vacuum charger and auto constant temperature dryer hopper, it possesses features of high production, good plasticizing and stable extruding.

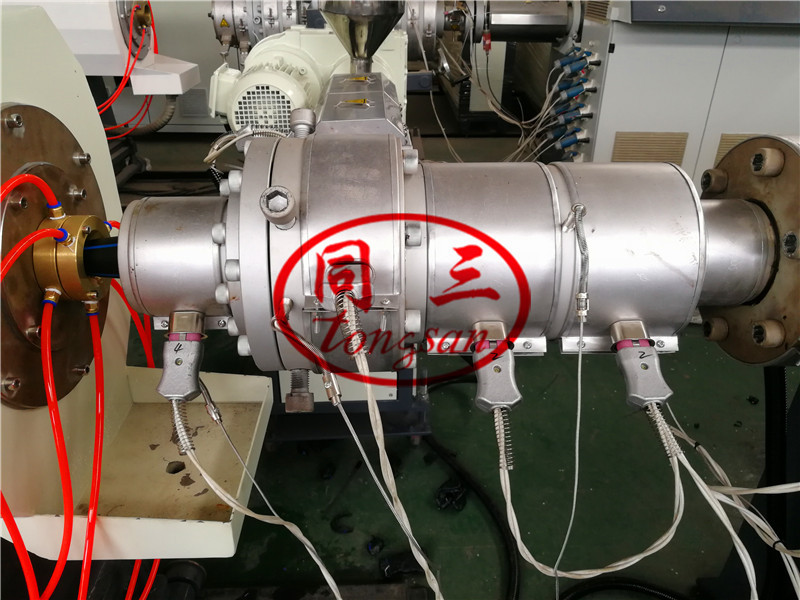

Die heads of helical type and basket type are perfect for polyethylene, and can help to produce sound melting pressure, and improve the plasticizing capacity. Meanwhile, stable material-flow and pressure grade can be guaranteed.

Advanced vacuum calibrating method improves the cleanliness and hardness of surface.

Caterpillar of the hauling machine adopts anti abrassion alloy material, which realizes stable traction, wide frequency adjustment range and long lifespan.

according to the PE pipe size, we shall equip double caterpillar haul off, three caterpillar haul off, four caterpillar haul off, six caterpillar haul off.

New generation auto dust-free cutting blade realizes smooth cutting secant, high preciison and low noise.

the cutter is equipped with PLC touch screen system,

the user can set the cutting length and it shall cut automatically.

You need a product

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram