plastic roof sheet making machine /roofing sheet making machine /screw and barrel for plastic extruder machine

group namePlastic Hollow Corrugated Sheet Machine

-

Min Order1 piece

brand nametongsan

modelSJ100/36 SJ120/36 SJ150/36 SJ80/36

payment methodL/C, Western Union, MoneyGram, T/T, Paypal, cash

-

update timeThu, 10 Dec 2020 15:25:07 GMT

Paramtents

material pp with masterbatch

screw type single screw high efficiency

screw material 38 Crmoala

cooling water

screw LD 36:1

application packing, turnover box

Packging & Delivery

Min Order1 piece

Briefing

Detailed

PP hollow sheet is mainly used in various fields of machinery, electron, appliance, food, advertising, interior decoration material, glass agricultural product etc packing and transporting.

The sheet has the advantages of non-toxic, no smell, pollution-free, anti-moisture, corrosion resistance, light quality, tough-resistance, thermal shock proof, economy and durability, rich colors etc.

It processes other advantages, like folding resistance, stretching resistance, strong bearing force.

plastic roof sheet making machine /roofing sheet making machine

Machine model and Technical parameter

|

Model |

Sheet width |

Sheet thickness |

Extruder Model |

Motor Power |

|

TS-1400 |

1250mm |

1.5-12mm |

100/36 |

55-75kw |

|

TS-1800 |

1700mm |

1.5-12mm |

120/36 |

75-90kw |

TS-2300 | 2150mm | 1.5-12mm | 120/36 | 90-110kw |

TS-2600 | 2450mm | 1.5-12mm | 120/36 | 90-110kw |

TS-3000 | 2800mm | 1.5-12mm | 150/36 | 132kw |

plastic roof sheet making machine /roofing sheet making machine

1) The plastic hollow sheet is eco-friendly new material in the market.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) The plastic hollow sheet has wide market prospect.

4) Running in a high automatization and intellectualization,no pollution .

5) Excellent Configuration, Stable Operation, High Production Efficiency.

plastic roof sheet making machine /roofing sheet making machine:

Loader with dryer system

Stainless steel hopper

Hot air dryer

Agitator

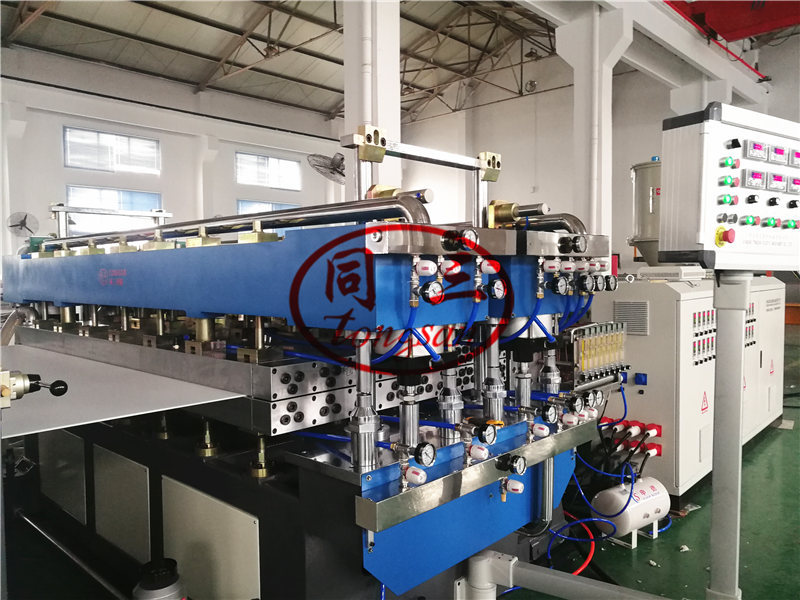

Single Screw Extruder

The specially designed screw and the advanced controlling system ensure excellent plasticization,high output and stable extruding.

We also have the co-extrusion type to use the recycled plastic to reduce the cost with high quality products.

Hydraulic Screen Changer without shutdown

Heating type heating rods

Working pressure 10-20mpa

Quick screen changer of hydraulic system ensure the continuously working of screen changing.Double position combined with special

sealing structure guarantee stable operation of screen changer.

Mold

Mold material Alloy steel forging.

Heating type Heating rods.

Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips,and also differential action of up-down piece guarantee even thickness of the plate.

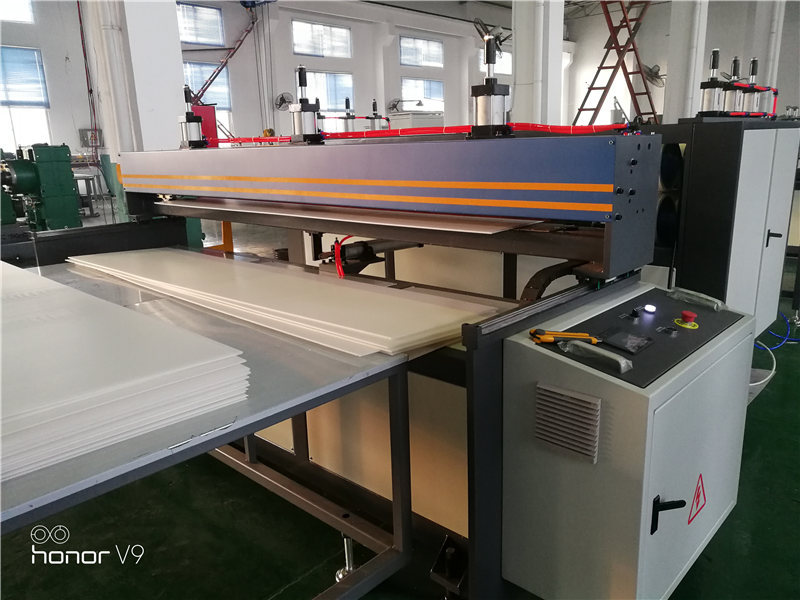

Vacuum forming machine

Mold material Alloy steel casting

Cooling medium Water

Calibrating type Minus pressure molding

Vacuum pump power 11kw

Vacuum tank type Slot type

Air fan power 1.5kw

Mold elevation type Pneumatic

Back-and–forth movable distance 100cm

Six –roller pull off machine

Rubber material Silicone rubber

Pull off line speed 1-8 m/minute

Clamp type Pneumatic

Motor type 7.5kw

Heating Oven

Model 2300

Heating type Heating rods

Heating power 30kw*2 sets

Elevation type Pneumatic

Cover insulation type Rock wool

Three–roller pull off machine

Rubber material Silicone rubber

Pull off line speed 1-8 m/minute

Clamp type Pneumatic

Motor power 4kw

Double-side corona

In order to improve the surface tension of the hollow sheet surface, and thereby improve the printing ink fastness, the hollow corrugated sheet surface will under corona treatment, so that the surface produces micro-concave dense holes, plastic surface roughening, increase the surface activity.

Transverse Cross cutting unit

Cutting thickness : 8-12mm

Clamping type :PPneumatic

Metering type:Rotary encoder Autonics brand

Power of motor : 2.2kw

Cutting type: Automatic

Back-and -forth moving type : Pneumatic

Control cabinet for PP corrugated sheet extrusion line

1, ABB inverter motor

2, Siemens contractor

3, Omron temperature control

4, English button

5, ventilation on each panel

6, number mark on each cable

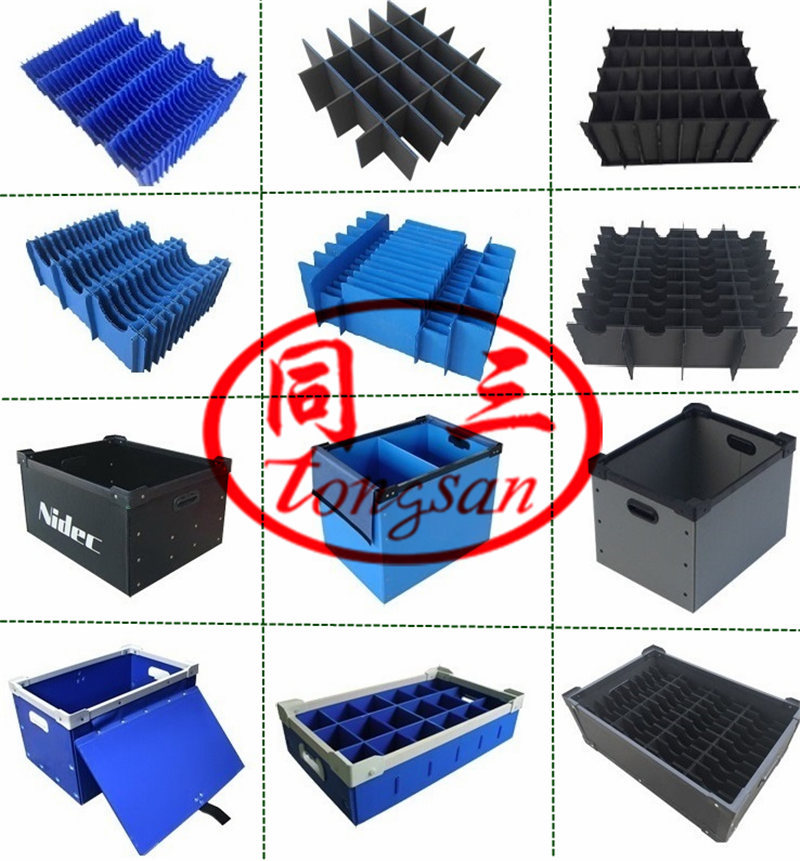

Final Product

The hollow sheet is widely used in machinery,electron,appliance,food,advertising,interior decoration material,glass,agricultural product etc packing and transporting. With the developing of e-commerce,the container is used largely more and more ,the logistics industry proposes high demand for the packing materials which are easier to use and transport,require simply technology and can be finished in short time.

Application Of PP Hollow Corrugated Sheet

1, Application of PP Plastic Hollow Corrugated sheet/Plate in Fruit,Vegetable and Food Packaging

PP plastic hollow packing box has excellent moisture resistance, water resistance, low temperature resistance, light and high strength, non-toxic, environmentally friendly, recyclable and reusable features, etc.Products: Apple Store Packing Box, Ginger Packing Box, Asparagus Packing Box, Grape Packing Box, Milk Packing Box, Variety Packing Box, Dairy Packing Box, etc.

2, Application of PP Plastic Hollow Corrugated sheet/Plate in Industrial Packaging

PP plastic hollow plate is widely used in the field of industrial packaging, because of its light and high strength, good buffer performance, good weather resistance, environmental recyclable reusable.PP plastic hollow plate industrial logistics turnover box product line is very rich, there are double-layer fixed turnover box, single-layer fixed turnover box, single-layer folding turnover box, matching knife card pad, storage cage enclosure, etc. According to the function can be divided into electronic turnover box, auto parts turnover box, logistics turnover box and so on; can meet the logistics turnover needs of all kinds of enterprises.

3, Application of PP Plastic Hollow Corrugated sheet/Plate in Packaging of Glass Bottles

With the continuous improvement of the quality requirements of glass bottles, the traditional packaging of sacks cannot meet the needs of production and market. Tray packaging can overcome the drawbacks of sack packaging, can reduce the packaging and transportation of glass bottles broken, but also to avoid the sack after a long time on the bottle ash and even adhered to the bag of decay.PP plastic hollow plate according to the customer's requirements, sealing edge, sealing angle to produce a variety of high strength and size of glass tray packaging plate.

4, Application of PP Plastic Hollow Corrugated sheet/Plate in Advertising Decoration and Advertising Printing

PP Plastic is dedicated to improving the quality of hollow plate, research and development of plastic hollow plate deep processing. develop different processes according to different products. Made of indoor and outdoor advertising exhibition display board, publicity posters, dairy drinks and wine display box and other products, this product has waterproof and moisture-proof, anti-aging, exquisite printing, long use time, beautiful and generous, overall vision and other characteristics.

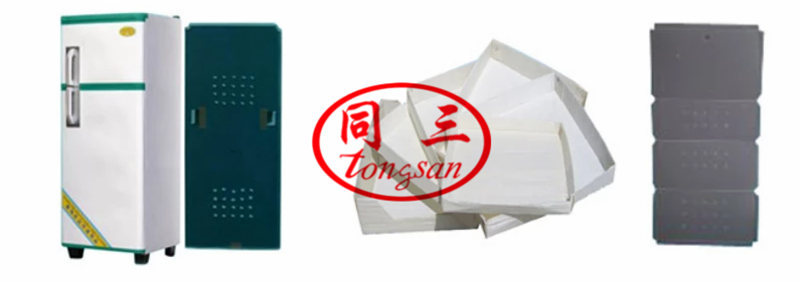

5, Application of PP Plastic Hollow Corrugated sheet/Plate in Refrigerator and Washing Machine

PP plastic hollow plate is a new type of environmental protection products, no pollution, no harm, meet the requirements of green environmental protection. The product has large internal quality, flat surface, high breaking strength, flame retardant, good moisture-proof performance, zero surface water and steam penetration, heat insulation, good energy saving effect. Especially the refrigerator with external condenser has excellent adiabatic effect. The company can make all kinds of refrigerator, freezer, washing machine back and base according to customer's request

1, Die cutting machine for making required shape and size for pp packing box production

2,PP box printing machine

we also can design die cutting and printing machine in an automatic production line.

it shall include PP hollow sheet auto feeder--- PP hollow sheet auto printing--- PP hollow sheet auto die cutting---PP hollow sheet auto convey---PP hollow sheet auto stacker

3, stitching the two sheets by rivets, flat wire or welding, etc., the stitching seal can be sealed by fiber tape or glue or magic paste.

1,We have all series plastic hollow corrugated sheet making machine in production,warmly welcome to visit our factory for machine running.The machine running is the best prove of the machines' quality ,the good quality machine is the granulating for the high effective production.

2,We can testing the machine according customer's formula.One is the customer can inspect the quality of our machine,another is the customer can check the quality of the products,so it is easy to calculate the cost of the sheet and the production capacity of our machines.So it's easy to calculate the investment pay back and increase the feasibility of the project.

3,We are professional for the auxiliary machine for sheet raw material making and plastic boxes making.We can provide the plastic filler masterbatch granulating making machine,the wast sheet crusher,the raw material mixing machine,the die cutting machine,the corona treatment machine,the sheet printing machine,the welding / bookbind machine .

4,Our engineer oversee installation and debugging ,our engineer with rich experience and will teach customer's worker about the operating one by one.And we provide long life time technical support.

You need a product

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram