Wood Plastic WPC Profile Extrusion Line Using Recycled PP/PE PVC Plastic and Wood Fiber

group namePP PE WPC Profile Machine

-

Min Order1 piece

brand nametongsan

modelSJ65/132

payment methodL/C, Western Union, MoneyGram, T/T, Paypal, cash

-

update timeWed, 13 Jan 2021 13:00:48 GMT

Paramtents

Plastic Material PE/PP/PVC Recycled Plastic Material

Wood Material Wood Sawdust/Rice Husk/Straw/Cotton Straw

Processing Mixing, Granulating, Extrusion

Mchine WPC Profile Extrusion Line

Packging & Delivery

Min Order1 piece

Briefing

ECO friendly

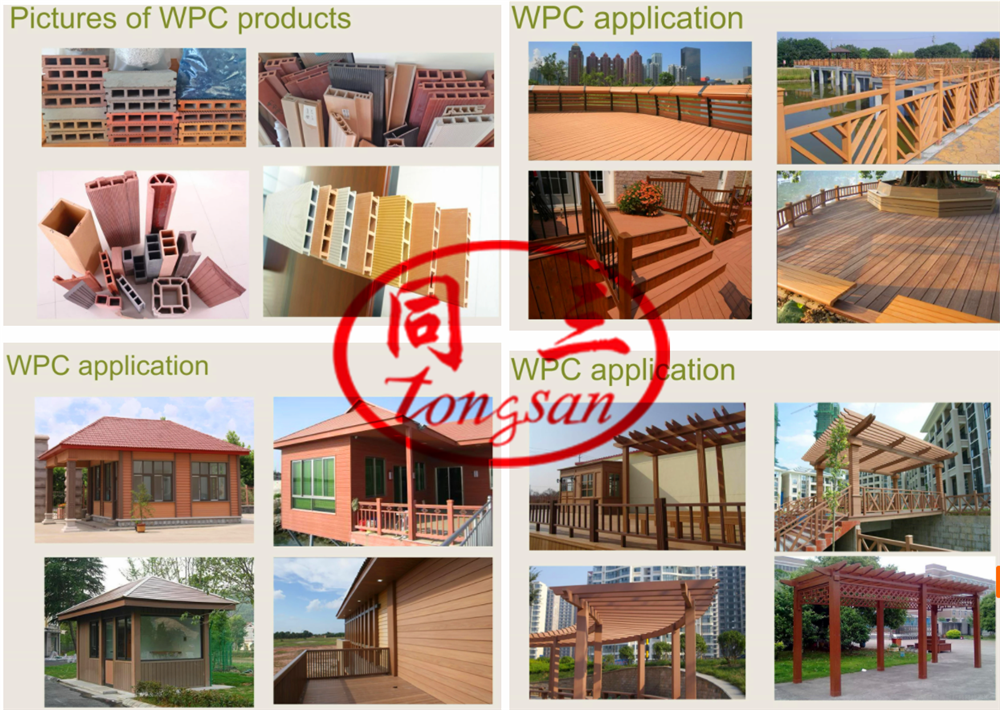

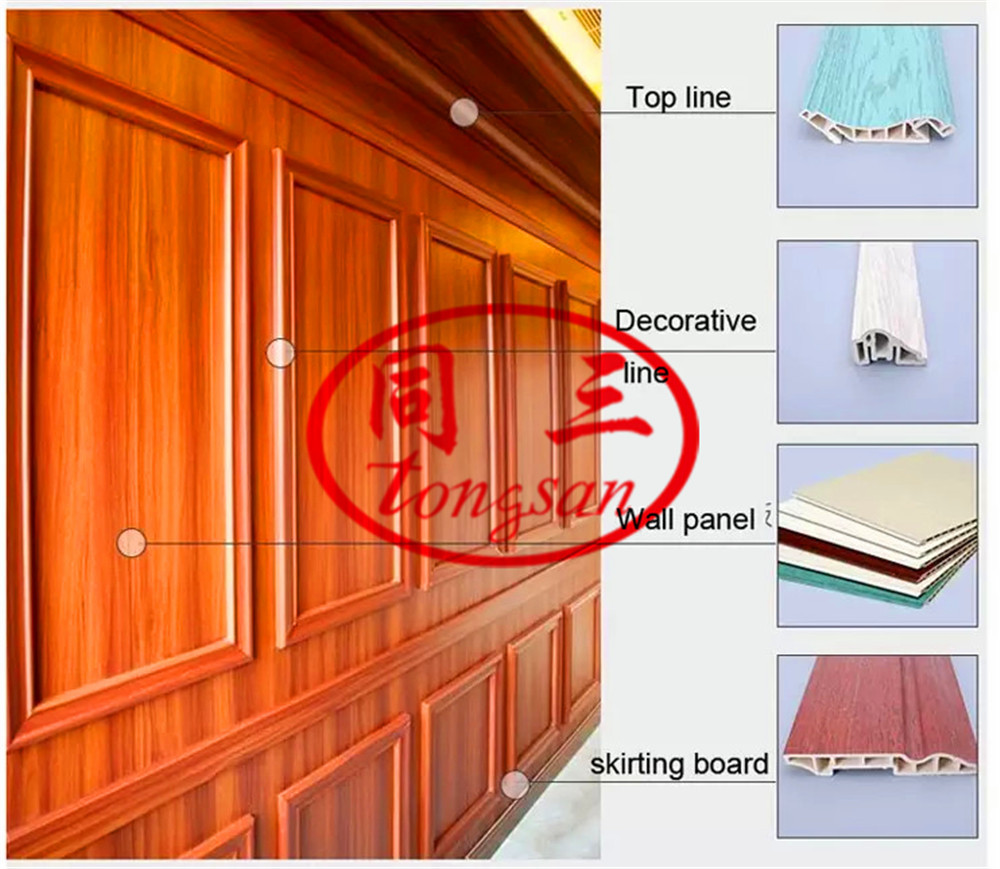

finish product: window and door frame, ceiling, wall,decking, pergola, fence

Detailed

|

Plastic material

|

recyccled PP/PE plastic

|

|

Wood material

|

wood powder from rice husk/straw,wheat husk/straw,wood sawdust,wastage wood

|

|

Percentage of plastic

|

25-30%

|

Percentage of wood powder | 50-70% |

Final product | WPC decking, WPC wall cladding, WPC pergola profile, WPC fence profile, and other WPC construction profiles |

|

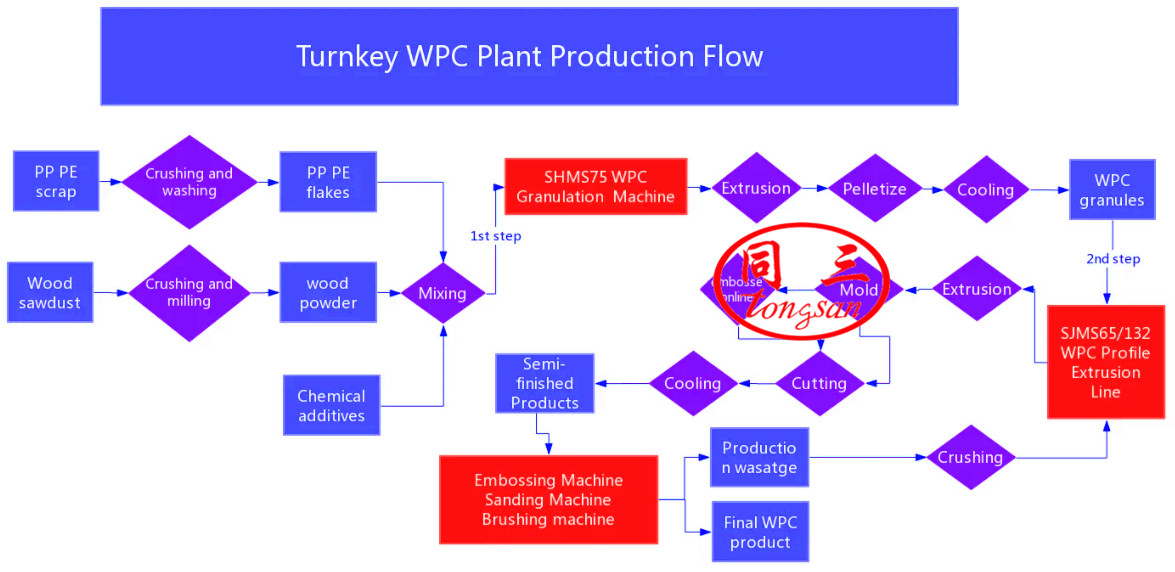

Production process

|

raw material--mixing--granulation--extrusion and molding--surface treatment

|

We have many WPC machine in stock for sale. fast delivery is avaliable

|

Project size

|

Smallest plant

|

Growing plant

|

Most effective plant |

Ideal plant

|

|

Project machine FOB cost

|

80000-100000 USD

|

130000-170000 USD

|

250000-340000 USD |

360000-500000 USD

|

|

Project capacity

|

1500 kgs per day

(24 hours running) |

3000 kgs per day

(24 hours running) |

9000 kgs per day (24 hours running) |

18000 kgs per day

(24 hours running) |

|

Project factory size

|

300 m2

|

500 m2

|

1000 m2 |

2000 m2

|

HGMSE series PP/PE WPC profile production line can continuously produce PP/PE WPC profile.

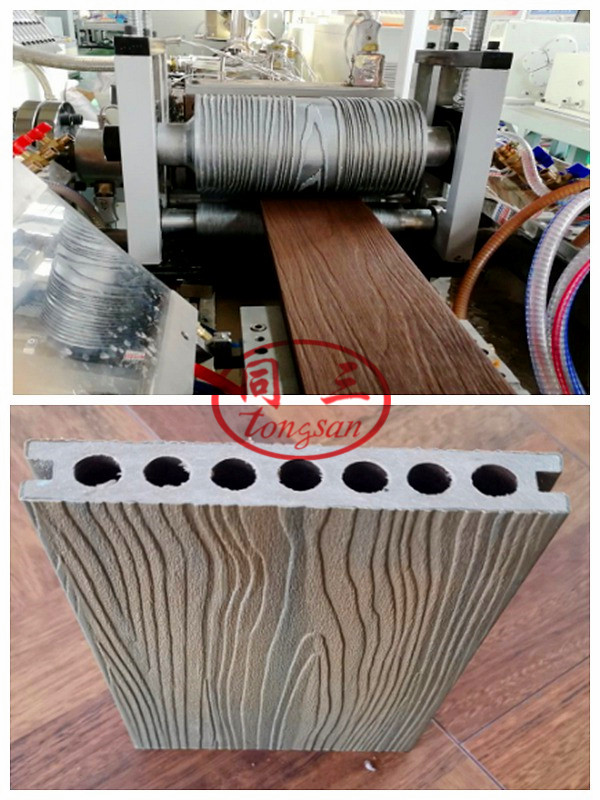

The WPC profile adopts two-step production process.The first step is using WPC granulating machine to make WPC pellets from recycled PP/PE material,wood powder and chemical additives.The max wood percentage can be 70%.The the WPC profile extrusion line will make the WPC pellets into WPC profiles by equip customized mold.We can equip on-line embossing machine to achieve 3D wooden pattern.

The profile produced by this production line can be sanded and brushed by sanding machine and brushing machine.

The machine adopt high quality parallel double extruder, which help the plastic completely be merged with wood and chemical additives. Double screw extruder also has the advantages of high output and good plasticization. The produced PP/PE WPC granules will be used to produce the WPC profiles

The PE WPC profile extrusion line is suitable for producing the hollow/solic PE WPC profiles.

This profile has the advantage of fireproof, waterproof, anticaustic, moisture proof, moth proof, mildew proof and environment friendly.

It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor lanscapes, pallets etc.

you can change mold to make different WPC profiles by the same machine

these machines is for making WPC products with better wooden feeling design.

item | machine discription | marks |

SJSZ65/132 pvc wpc door frame extrusion line | auto material loader | load material to extruder automatically |

SJSZ65/132 connical double screw extruder | mixing and melting material | |

mold: die + calibrating mold + water tank | change mold can get different shape and size | |

vacuum calibrating table 6m/8m/10m/12m | for product forming and cooling | |

haul off machine | double caterpillar | |

cutting machine | fixed length cutting | |

|

dust collector |

collect dust after cutting |

|

|

stacking machine |

product stacking |

|

auxilary machine |

300/600 mixer |

mix all material together |

water chiller | provide chilling water | |

|

air compressor |

provide compressed air |

|

wastage recycle machine | 360 crusher | recycle wastage on production to reuse |

500 miller | ||

surface treatment machine | laminating machine | get wooden grain |

ASA co extrusion |

You need a product

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram