End mill cutter for aluminum

group nameCarbide Endmills & Drills

-

Min Order1 piece

modelCarbide end mills for aluminum

payment methodL/C, Western Union, T/T, Paypal

-

update timeFri, 20 Sep 2019 11:36:36 GMT

Paramtents

Shape Flat/ball nose/corner radius

Application For working aluminum

Machine Type CNC machine

Hardness HRC45,HRC55,HRC65

Features For rough milling of aluminum (polished grooves).

Coating Uncoating

Workpiece material Aluminum and other nonferrous material

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Description: End mill cutter for aluminum

Product Name | End mill cutter for aluminum |

| Features | Variable helix angle and unequal flute spacing |

| Processing Type | Metal |

| Precision | within 0 ~-0.01mm |

| HRC | 45,50,55,65 |

| Suitable For | Aluminum and other non ferrous material |

| Machine Type | CNC Milling Machine |

| Flutes | 3 Flute |

| Specification | Standard sizes all are available |

| Co10 | 10% or 12% |

| TRS Min(N/MM²) | 4200 |

| HRA | 92.2-93 |

Why should we choose your company?

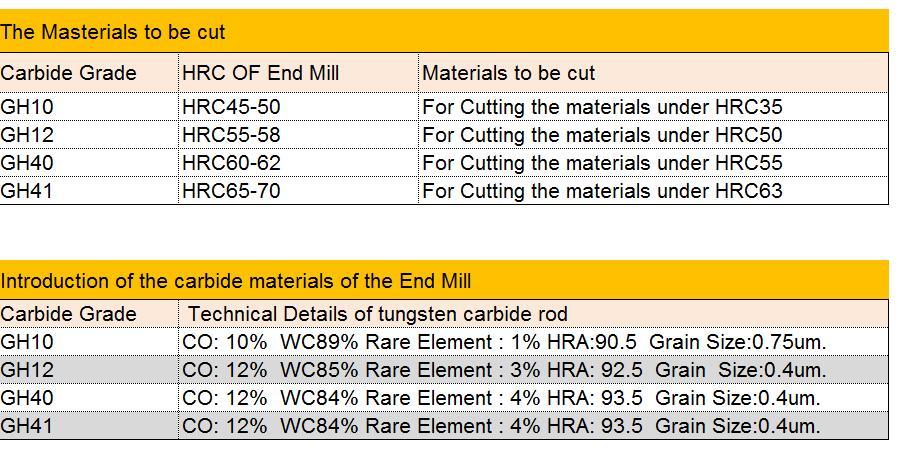

1.Super raw material

Except G&H Carbide rods, we also use Kennametal Carbide from USA, Sandvik Carbide from Sweden, CB Carbide from Taiwan.

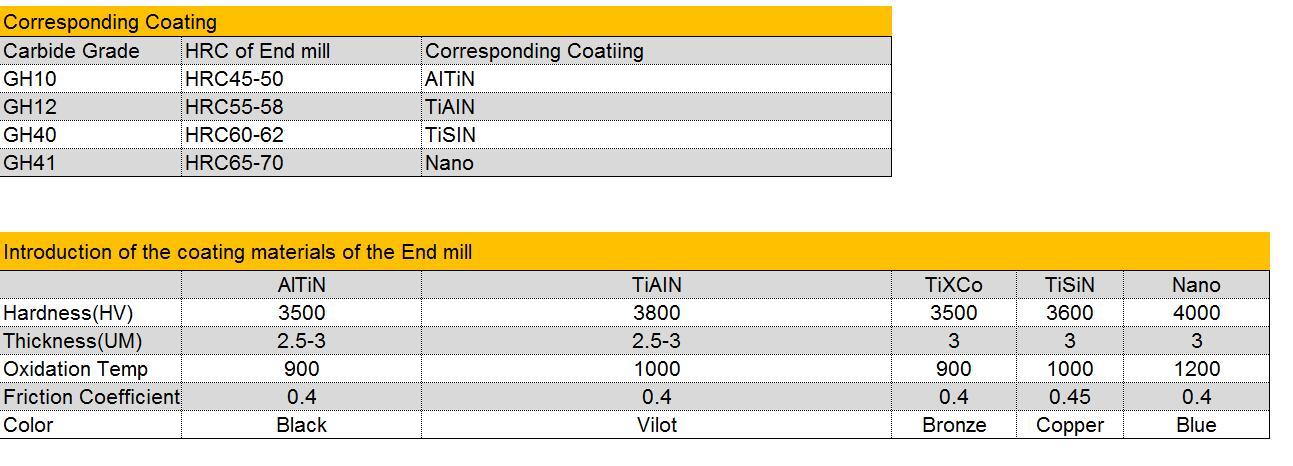

2.Super Coating

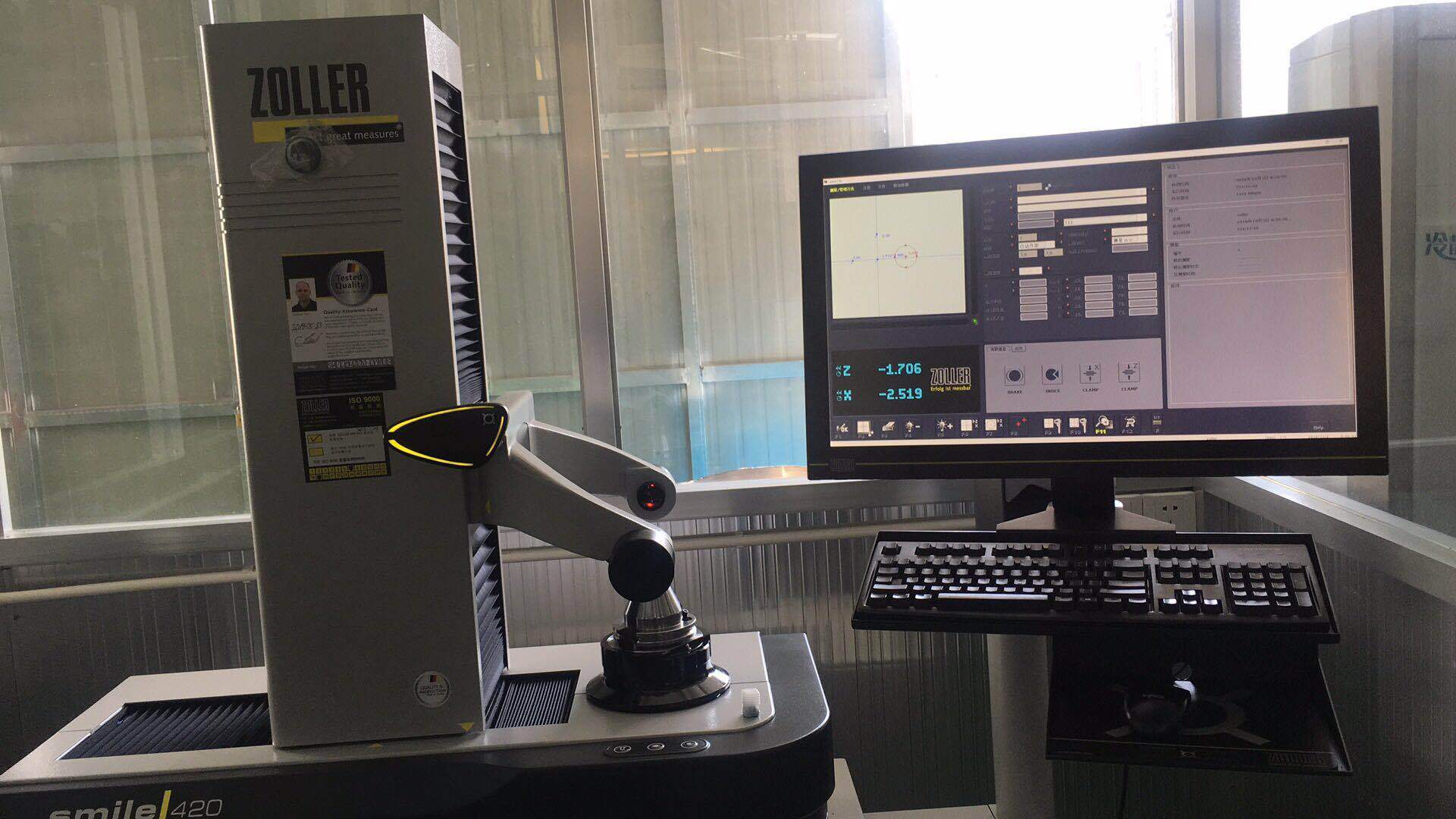

3.Advanced Equipment

- ANCA & WALTER for producing end mills

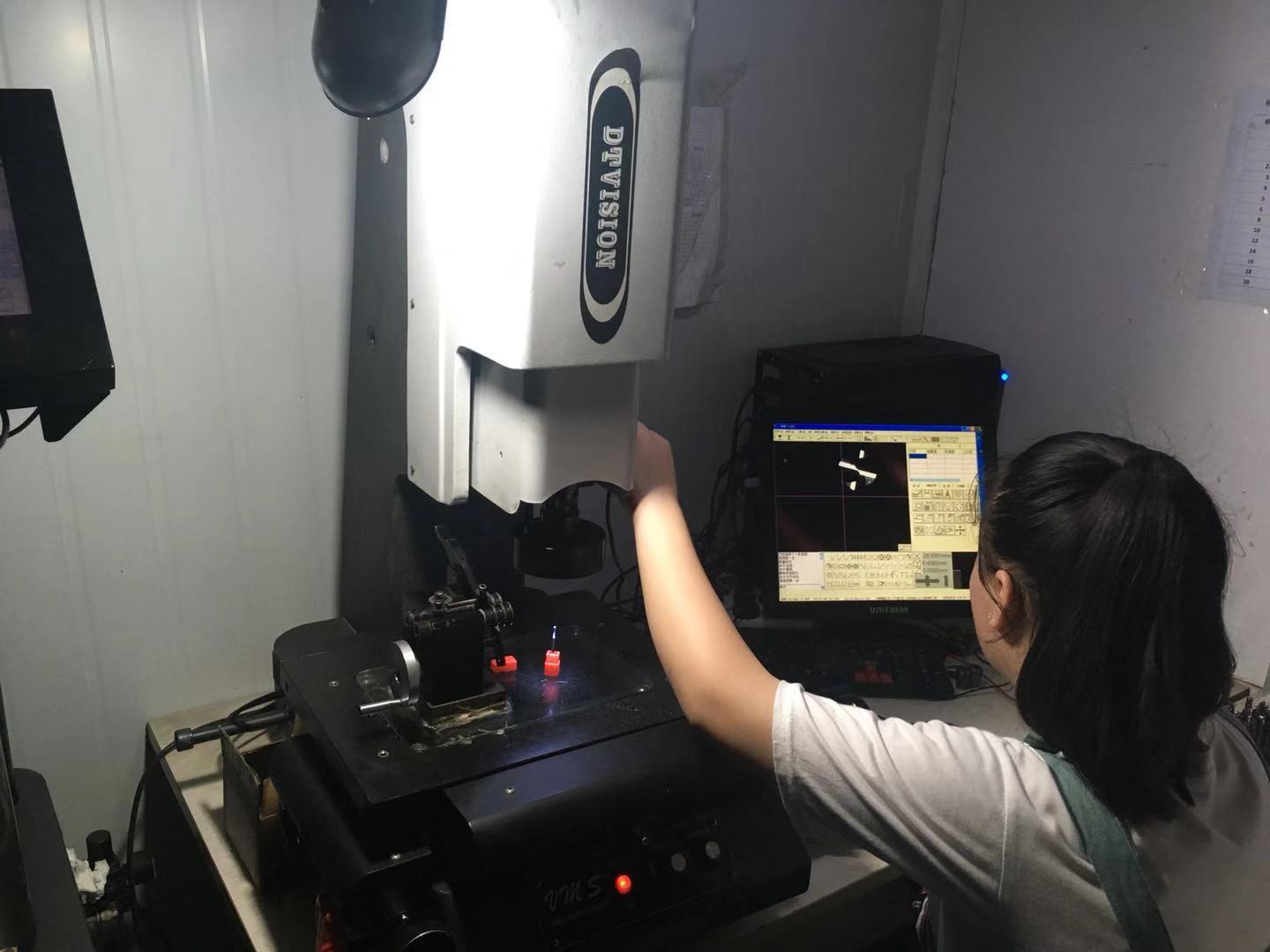

- PG1000 & PARLEC for detecting

4.Wide Application

HRC50 suitable for Iron, Cast Iron, Common Steel under hardness HRC45

HRC55 suitable for Iron, Cast Iron, Common Steel, Hardened Steel under hardness HRC55

HRC60 suitable for Pre-hardened steel; Stainless steel; Alloy steel; Die steel under HRC60

HRC65 suitable for Hardened steel; Mold steel; Die steel; Alloy steel above HRC60

5. Strict Quality Inspection

Related Products

You need a product

You May Like

- Delivery clauses under the trade mode

- FOB, CIF, EXW

- Acceptable payment methods

- T/T, L/C, PayPal, Westem Union