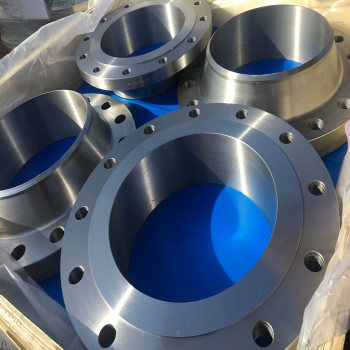

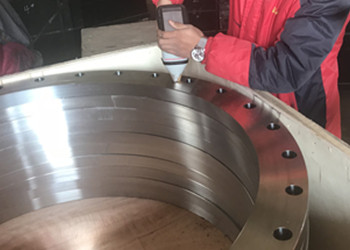

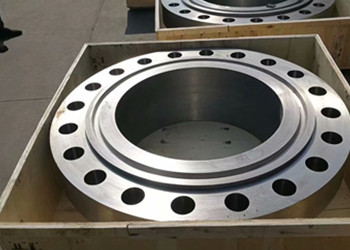

36'' ASME B 16.47 SER.A SER.B CS welding neck WNRF flanges

group nameSteel Pipe Flange ASME B 16.5

-

Min Order10 piece

brand nameJS FITTINGS

modelclass 150

payment methodL/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal, Crash

-

update timeThu, 14 May 2020 10:59:37 GMT

Paramtents

Brand JS FITTINGS

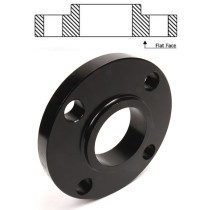

Seal Raised face Flat face

Connection Welding

Surface black painted, yellow painted, anti-rust oil

Pressure 75cl, 150cl, 300cl, 600cl, 900cl

Packging & Delivery

Size110cm x 110cm x 100cm

Min Order10 piece

Briefing

Detailed

NPS | OD | D | B | B | H | A | G | K | L | No of Bolts | Stud Bolt | |

(WNF) | (BLF) | |||||||||||

26 | 660.4 | 870 | 66.7 | 66.7 | 119 | 676 | 749 | 806.4 | 34.9 | 24 | 1¼ | 222 |

68.3 | 68.3 | 120.6 | ||||||||||

28 | 711.2 | 925 | 69.9 | 69.9 | 124 | 727 | 800 | 863.6 | 34.9 | 28 | 1¼ | 228 |

71.5 | 71.5 | 125.6 | ||||||||||

30 | 762 | 985 | 73.1 | 73.1 | 135 | 781 | 857 | 914.4 | 34.9 | 28 | 1¼ | 234 |

74.7 | 74.7 | 136.6 | ||||||||||

32 | 812.8 | 1060 | 79.4 | 79.4 | 143 | 832 | 914 | 977.9 | 41.3 | 28 | 1½ | 266 |

81 | 81 | 144.6 | ||||||||||

34 | 863.6 | 1110 | 81 | 81 | 148 | 883 | 965 | 1028.7 | 41.3 | 32 | 1½ | 266 |

82.6 | 82.6 | 149.6 | ||||||||||

36 | 914.4 | 1170 | 88.9 | 88.9 | 156 | 933 | 1022 | 1085.8 | 41.3 | 32 | 1½ | 279 |

90.5 | 90.5 | 157.6 | ||||||||||

38 | 965.2 | 1240 | 85.8 | 85.8 | 156 | 991 | 1073 | 1149.4 | 41.3 | 32 | 1½ | 279 |

87.4 | 87.4 | 157.6 | ||||||||||

40 | 1016 | 1290 | 88.9 | 88.9 | 162 | 1041 | 1124 | 1200.2 | 41.3 | 36 | 1½ | 279 |

90.5 | 90.5 | 163.6 | ||||||||||

42 | 1066.8 | 1345 | 95.3 | 95.3 | 170 | 1092 | 1194 | 1257.3 | 41.3 | 36 | 1½ | 292 |

96.9 | 96.9 | 171.6 | ||||||||||

44 | 1117.6 | 1405 | 100.1 | 100.1 | 176 | 1143 | 1245 | 1314.4 | 41.3 | 40 | 1½ | 304 |

101.7 | 101.7 | 177.6 | ||||||||||

46 | 1168.4 | 1455 | 101.6 | 101.6 | 184 | 1197 | 1295 | 1365.2 | 41.3 | 40 | 1½ | 304 |

103.2 | 103.2 | 185.6 | ||||||||||

48 | 1219.2 | 1510 | 106.4 | 106.4 | 191 | 1248 | 1359 | 1422.4 | 41.3 | 44 | 1½ | 317 |

108 | 108 | 192.6 | ||||||||||

50 | 1270 | 1570 | 109.6 | 109.6 | 202 | 1302 | 1410 | 1479.6 | 47.6 | 44 | 1¾ | 336 |

111.2 | 111.2 | 203.6 | ||||||||||

52 | 1320.8 | 1625 | 114.3 | 114.3 | 208 | 1353 | 1461 | 1536.7 | 47.6 | 44 | 1¾ | 349 |

115.9 | 115.9 | 209.6 | ||||||||||

54 | 1371.6 | 1685 | 119.1 | 119.1 | 214 | 1403 | 1511 | 1593.8 | 47.6 | 44 | 1¾ | 355 |

120.7 | 120.7 | 215.6 | ||||||||||

56 | 1422.4 | 1745 | 122.3 | 122.3 | 227 | 1457 | 1575 | 1651 | 47.6 | 48 | 1¾ | 361 |

123.9 | 123.9 | 228.6 | ||||||||||

58 | 1473.2 | 1805 | 127 | 127 | 233 | 1508 | 1626 | 1708.2 | 47.6 | 48 | 1¾ | 374 |

128.6 | 128.6 | 234.6 | ||||||||||

60 | 1524 | 1855 | 130.2 | 130.2 | 238 | 1559 | 1676 | 1759 | 47.6 | 52 | 1¾ | 381 |

131.8 | 131.8 | 239.6 | ||||||||||

OD = Diameter at Weld Bevel

D = Overall Diameter of Flange

B (WNF) = Minimum Thickness of Welding Neck Flange

B (BLF) = Minimum Thickness of Blind Flange

H = Length thru Hub

A = Diameter at Base of Hub

G = Outside Diameter of Raised Face

K = Bolt Circle Diameter

L = Diameter of Bolt Holes

|

FLANGE STANDARD |

PRESSURE RATING |

TYPE |

Sealing Face |

|

ANSI B16.5 |

CLASS 150, CLASS 300, CLASS 400, CLASS 600, CLASS 900, CLASS 1500, CLASS 2500 |

SO WN SW TH LJ BL LWN |

Raised Face |

|

ANSI B16.47-A MSS |

CLASS 150, CLASS 300, CLASS 400, CLASS 600, CLASS 900 |

WN BL |

|

|

ANSI B16.47-B API |

CLASS 75, CLASS 150, CLASS 300, CLASS 400, CLASS 600, CLASS 900 |

||

ANSI/ASME B16.36 | CLASS 300, CLASS 400, CLASS 600. CALSS 900 CLASS 1500 CLASS2500 | ORIFICE | |

ANSI/ASME B16.48 | CLASS 150 CLASS 300 CLASS 400 CLASS 600 CLASS 900 CLASS 1500 CLASS 2500 | FIG.8 | |

AWWA C207 | CLASS B & D TABLE 2/3, CLASS E TABLE 4 | SO PL BL | |

EN 1092-1 | PN 2.5 6 10 16 25 40 63 100 160 250 320 400 | PL LOO BL WN SO TH | |

BS 4504 | PN 2.5, PN 6, PN 10, PN 16, PN 25, PN 40 | PL WN TH BL SO | |

DIN | PN 6 PN 10, PN 16, PN 25, PN 40 | PL WN TH BL LOO SO | |

UNI | PN 6 PN 10, PN 16, PN 25, PN 40 | PL WN TH BL LOO | |

SABS/SANS 1123 | 1600/3, 1600/4 | WN PL TH SO BL | |

JIS B2220/KS | 5K 10K 16K 20K 30K 40K | SOP/PL SOH/SO BL | |

GOST | PN 6, PN 10, PN 16, PN 25, PN 40, PN 63, PN 100, PN 160 | PL WN BL | |

BS | TABLE D E F H | PL SO BL |

You need a product

You May Like

- Nearest port for product export

- Tianjin Xingang, Qingdao

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, MoneyGram, Westem Union, Cash