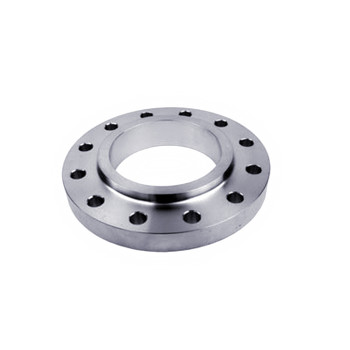

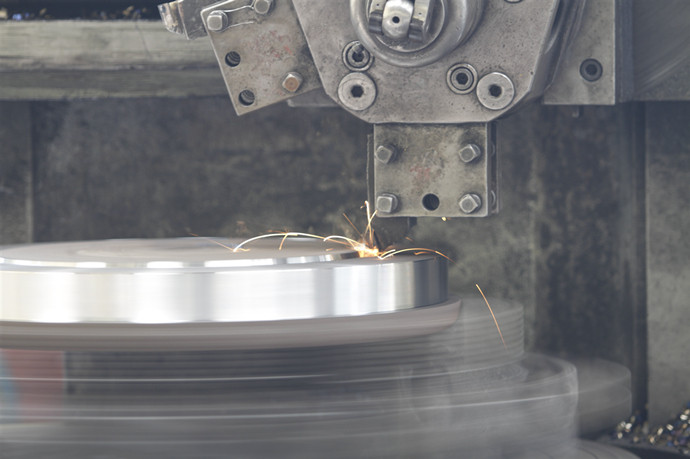

Forged steel flange carbon steel astm a105 SO flange

group nameSteel Pipe Flange ASME B 16.5

-

Min Order1 piece

brand nameJS FITTINGS

modelhigh-pressure blind flanges

payment methodL/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal

-

update timeWed, 25 Aug 2021 16:23:15 GMT

Paramtents

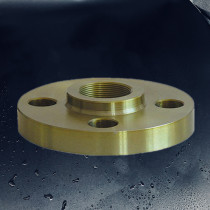

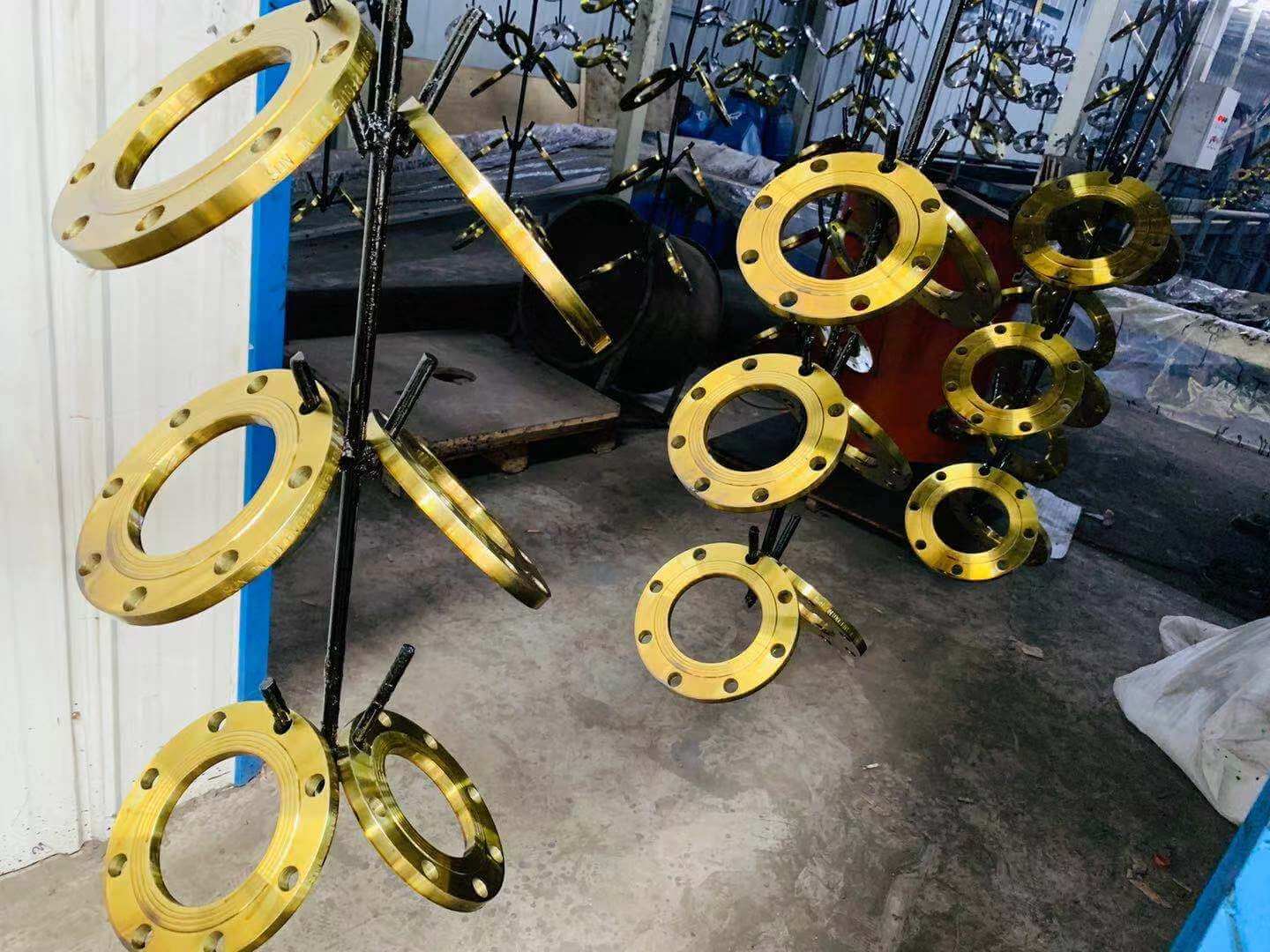

Color Golden, black, red

Size 1/2

pressure Medium and low pressure flange

Material carbon steel, stainless steel, alloy steel

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Special customized diameters: up to 60”.

Material Types: Stainless Steel, Alloy Steel, Carbon Steel

Class range: Class 150 to 2500. PN 2.5 to PN 250.

Flange face type: RF, RTJ

Octal offers slip on flange with materials standards in ASTM A105, ASTM A182, ASME B16.5, BS 3293, DIN 86029.

1. Installation costs are lower

2. Less time is spent on accurately cutting the pipe

3. Easier alignment

4.Low hub on slip-on flanges due to pipe slips in the flange

5. Interior and outer welding of flange

6. Leak prevention

On the other hand, as the flange bore is bigger than pipeline diameter, it usually requires more welding work than the other flanges, moreover as the durability is not expected as longer as Welding Neck Flange, so all these factors shall be considered before choose a slip on flange.

ASTM A182 for alloy and stainless slip on flanges. (Alloy for F11, F22, stainless for F304/F304L, F316/F316L)

ASME B16.5 for pipe flanges and flanged fittings.

BS 3293

DIN 86029

Special made outer diameters: up to 60”.

Class range: Class 150, Class 300, 400, 600, 900, 1500, 2500(# or LB). PN 2.5 to PN 250.

Flange face type: RF (Raised Face), RTJ (Ring Type Joint)

You need a product

You May Like

- Nearest port for product export

- Tianjin Xingang, Qingdao

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, MoneyGram, Westem Union, Cash