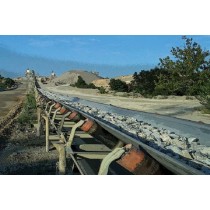

Long distance belt conveyor used for bulk material with large conveying capacity

group nameOverland Belt Conveyor

-

Min Order1 set

brand nameSKE

modelB800/B1000/B1200/B1400

payment methodL/C, Western Union, T/T

-

update timeFri, 19 Jun 2020 12:19:32 GMT

Paramtents

color To be confirmed with client

length Based on the layout requirement

capacity 800-2000 tph

supporting design steel supporting or corridor

Packging & Delivery

Min Order1 set

Briefing

Detailed

You need a product

You May Like

- Nearest port for product export

- Shanghai,China

- Delivery clauses under the trade mode

- FOB, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Westem Union