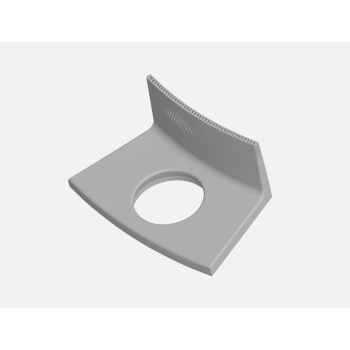

Custom Turbine Casing Nickel Alloy Titanium Inconel 713 718 Casting OEM ODM Support

group nameGas Turbine Wheel Parts

-

Min Order1 piece

brand nameOBT casting part Manufacturer

payment methodT/T, L/C, D/P D/A, MoneyGram, PayPal, Westem Union, Cash, Escrow

-

update timeMon, 23 Oct 2023 17:49:31 GMT

Paramtents

Material Inconel Hastelloy Incoloy Monel

OEM & ODM Services Available

Weight Custom

Tolerance 0.004mm

Smooth surface roughness Ra0.6-3.2

Packging & Delivery

Min Order1 piece

Briefing

Detailed

A turbine casing is a crucial component in a gas or steam turbine. It's an outer shell that encloses and protects the internal components of the turbine, such as the rotor, stator, and blades. The casing plays several essential roles:

Containment: It houses the rotating blades and stator vanes, preventing them from moving out of their designed path. This containment is vital for safety.

Aerodynamic Efficiency: The casing is shaped to optimize the flow of air or gas through the turbine. It helps direct the working fluid over the blades efficiently.

Pressure Maintenance: It helps maintain the pressure difference across the turbine. This is crucial for the generation of power or thrust.

Structural Integrity: The casing provides structural support to the internal components and must withstand high temperatures and pressures.

Accessibility: It allows for inspection and maintenance of the internal components.

Turbine casings are designed with great precision to ensure the efficient operation of the turbine while enduring extreme conditions. They are typically made from materials that can withstand high temperatures and pressures, such as nickel-based alloys or other high-temperature materials.

You need a product

You May Like

- Nearest port for product export

- Qingdao port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, PayPal, Westem Union, Cash, Escrow