Industrial Central Dust Collection System, Explosion Proof Cartridge Dust Collector

group nameSeries B-J | Pulse-jet Dust Collector with Dust Hopper

-

Min Order1 set

brand nameACMAN

modelTE-EX

payment methodT/T

-

update timeThu, 26 Feb 2026 15:23:37 GMT

Packging & Delivery

Min Order1 set

Briefing

Detailed

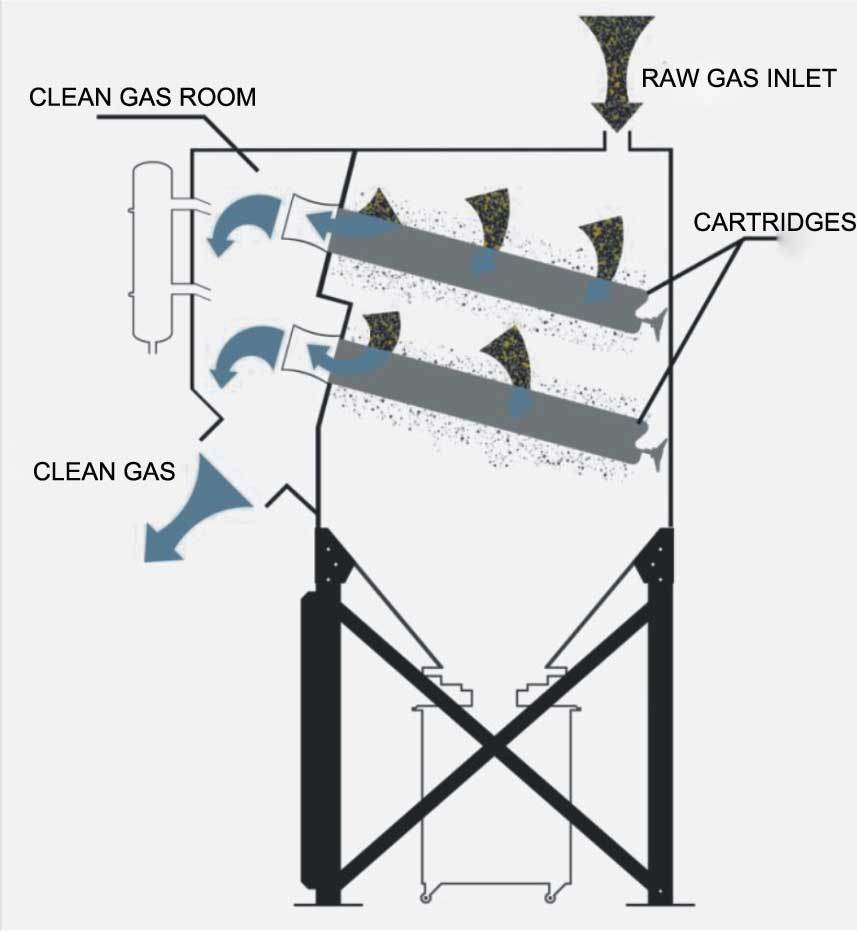

Easy to use

Quick-release handles provide easy cover removal and faster filter access

Compact

Smaller footprints for applications that require maximum cleaning efficiency in even smaller spaces

Powerful

Dust collectors provide 25 percent more capacity than same-sized dust collectors

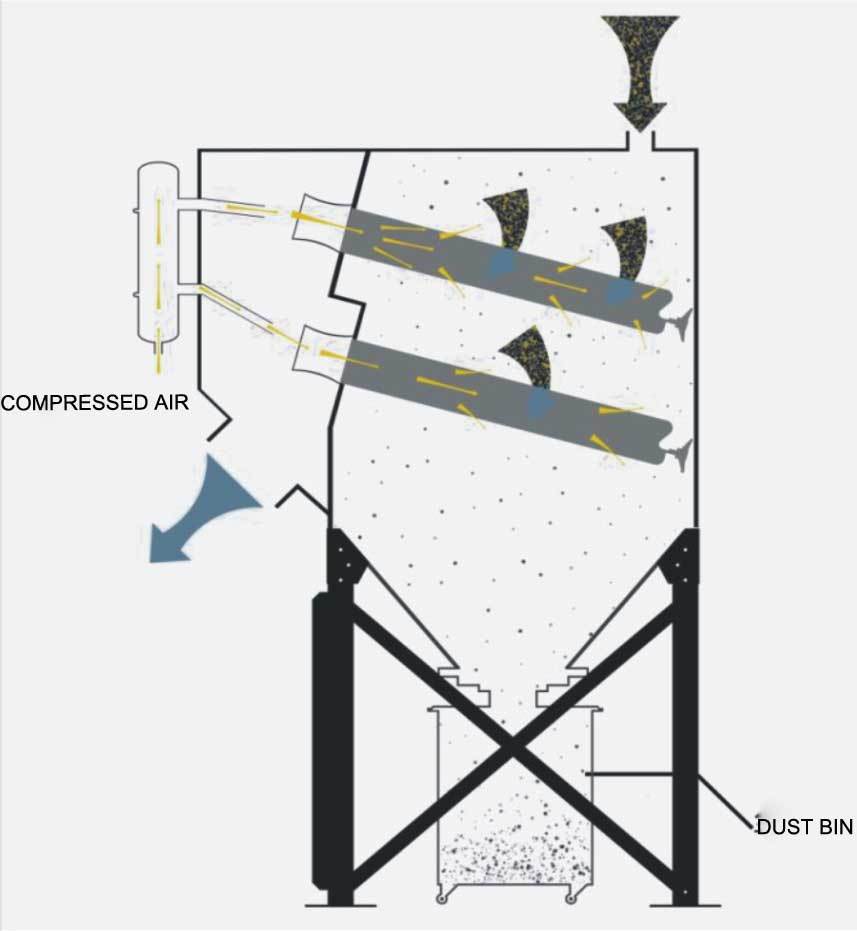

Cost Effective

The proprietary Filter Cleaning System averages up to 30 percent increase in pulse cleaning energy for unmatched cleaning ability

Innoative

Unique cartridge filters provide the longest filter life and highest filtration efficiency—which lowers cost

|

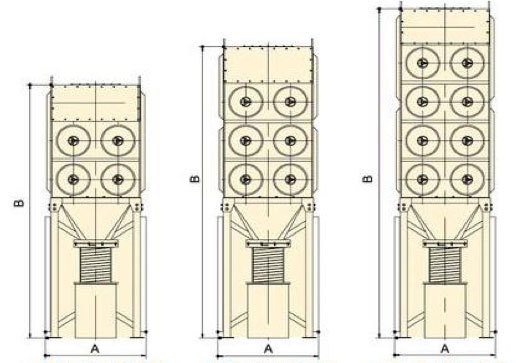

Model |

Air Volume(m³/h) |

Filter Area(m2) |

Size(mm) |

Efficiency |

TE-2-8 | 3600-7200 | 80 | 1000x2200x3320 | 99.9% |

TE-2-16 | 7200-14400 | 160 | 2000x2200x3320 | 99.9% |

TE-2-24 | 10800-21600 | 240 | 3000x2200x3320 | 99.9% |

TE-3-12 | 5400-10800 | 120 | 1000x2200x3790 | 99.9% |

TE-3-24 | 10800-21600 | 240 | 2000x2200x3790 | 99.9% |

TE-3-36 | 16200-32400 | 360 | 3000x2200x3790 | 99.9% |

TE-4-16 | 7200-14400 | 160 | 1000x2200x4250 | 99.9% |

TE-4-32 | 14400-28800 | 320 | 2000x2200x4250 | 99.9% |

|

TE-4-48 |

21600-53200 |

480 |

3000x2200x4250 |

99.9%

|

|

TE-4-64 |

28800-57600 |

640 |

4000x2200x4250 |

99.9%

|

|

TE-4-80 |

36000-72000 |

800 |

5000x2200x4250 |

99.9%

|

You need a product

You May Like

6YRS ACMAN ENVIRONMENT CO., LTD

- Nearest port for product export

- Ningbo, Shanghai

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow