3-in-1 Nutsche Filter Dryer soild-liquid separation dryer finechemical pharma China Amtech dryer

- US $20000.00

1 - 100 piece

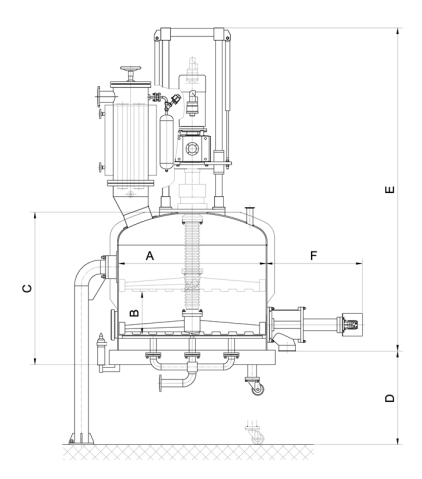

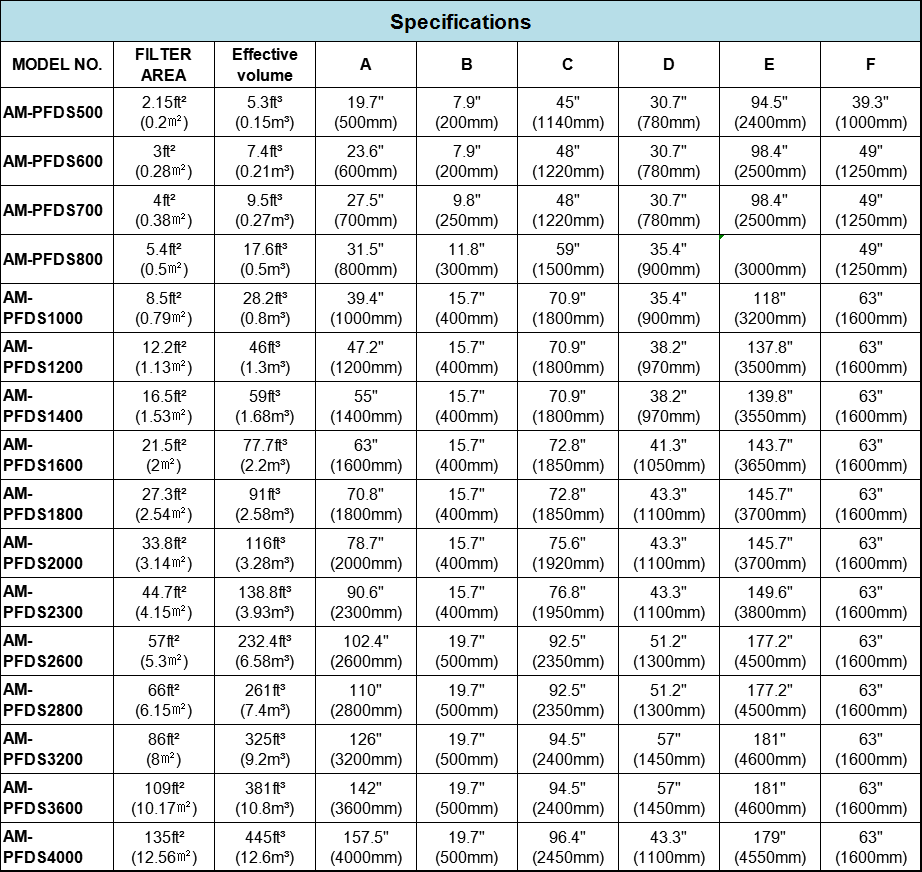

group nameNutsche Filter Dryer

-

Min Order1 piece

brand nameAmtech

modelAM-PFD

payment methodT/T

-

update timeMon, 06 Jul 2020 14:47:12 GMT

Paramtents

Material Stainless steel 304/316/316L

Usage Finechemical /pharma

Design Customized

Packging & Delivery

Size190cm x 130cm x 172cm

Weight1200.00kg / piece

Min Order1 piece

Briefing

Detailed

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, Shanghai Port

- Delivery clauses under the trade mode

- FOB, EXW

- Acceptable payment methods

- T/T, Westem Union