Leading steel pipe manufacturer offering galvanized hollow sections for embankment structures.

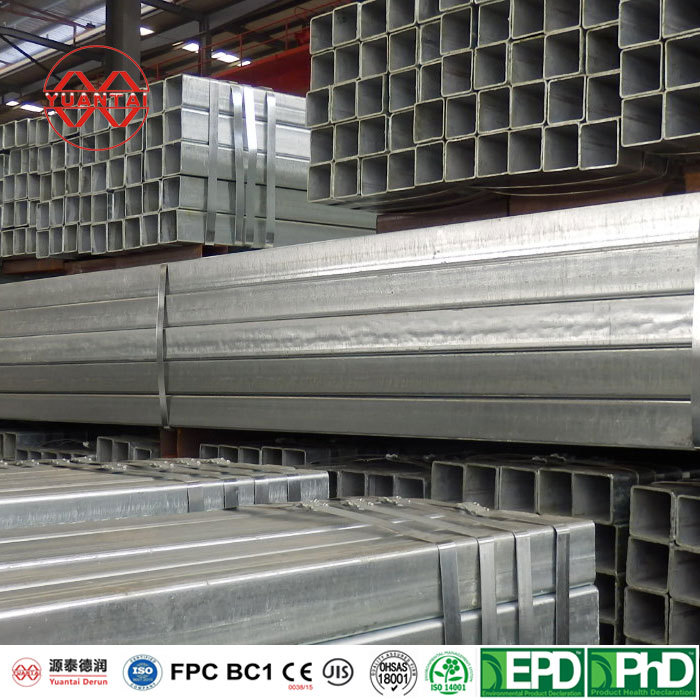

Galvanized hollow sections for embankment Structure

Hollow section for embankment structure overview

Embankments can be divided into steel dams, stone dams, and concrete dams. Steel dams are mainly made of steel products and are a facility that can effectively intercept river water. They have been applied in many parts of China, such as the discharge and drainage of some rivers or reservoirs. For example, many galvanized steel hollow sections are used in the Three Gorges Dam in China. It comes in many specifications and types, with different models and prices based on different shapes and sizes.

Introduction to Galvanized Hollow Sections

Galvanized hollow sections are structural steel profiles that are coated with a protective layer of zinc through the process of galvanization. This coating acts as a shield against corrosion, ensuring durability and longevity. Galvanized hollow sections are widely used in construction, infrastructure development, and other industries due to their exceptional strength and resistance to environmental factors.

Understanding Hollow Sections

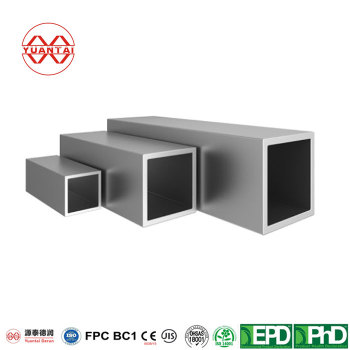

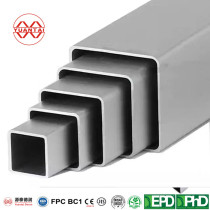

Hollow sections, also known as structural tubes, are hollow cylindrical or rectangular profiles made from steel. They are characterized by their closed geometric shape, offering superior load-bearing capacity compared to open sections. Hollow sections provide structural stability while minimizing weight, making them an ideal choice for designing lightweight yet robust structures.

Importance of Galvanization in Hollow Sections

Galvanization plays a crucial role in enhancing the performance and lifespan of hollow sections. By immersing the steel profiles in a bath of molten zinc, a galvanized coating is formed, which provides a barrier against moisture, chemicals, and other corrosive elements. This protective layer significantly reduces the risk of rust and corrosion, ensuring that the hollow sections maintain their structural integrity over time.

1.Material of galvanized hollow section for embankment structure

carbon steel ,alloy steel,stainless steel.The material of steel dams is usually high-quality steel, which has strong tensile strength and deformation resistance, and can work in different environments, effectively avoiding damage to the dam caused by river water impact.

Secondly, structural components welded from steel pipes are hot-dip galvanized on the surface, which can prevent corrosion and rusting of the steel structure and prolong its service life.

2.Product details of Galvanized hollow sections for embankment Structure

High corrosion resistance

Three Gorges Dam Project

The Three Gorges Dam is located in the Three Gorges Dam Tourist Area of Sandouping Town, Yiling District, Yichang City, Hubei Province. It is located in the Xilingxia section of the main stream of the Yangtze River, at the eastern end of the Three Gorges Reservoir, with a controlled drainage area of about 1 million square kilometers. It was founded in 1994 and integrates flood control, power generation, navigation, and water resource utilization. It is the main project of the Three Gorges Hydropower Station and the core landscape of the Three Gorges Dam Tourist Area One of the largest water conservancy hub buildings in the world today.

Role of Hot-Dip Galvanized Steel Pipe Wholesalers

Hot-dip galvanized steel pipe wholesalers play a vital role in the supply chain of galvanized hollow sections. These wholesalers source galvanized steel pipes from manufacturers and distribute them to various industries and construction projects. They act as a bridge between manufacturers and end-users, ensuring a seamless flow of galvanized hollow sections in the market.

Why choose Yuantai Derun?

- 1. 100% after-sales quality and quantity assurance.

- 2. Professional sales manager quickly reply within 24 hours.

- 3. Large Stock for regular sizes.

- 4. Free sample 20cm high quality.

- 5. Strong produce capability and capital flow.

- 6. Small order accepted.

- 7. Brand name raw material

- 8. Support OEM or ODM

- 9. 20 years Manufacturing experience

- 10. It can manufacture steel pipes of different projects and standards in the world

- 11. Yuantai has a standing stock of more than 200000 tons, and the annual shipment specification is:

- 20*20*1.0—1000*1000*50mm,square steel pipes

- 20*30*1.0—800*1200*50mm,rectangular steel pipes

- Φ 10.3— Φ 3620mm,circular steel pipes

- After the completion of the new base in Tangshan, the total production capacity will reach 10 million tons.

Exploring Square Tube Materials

Square tubes used for manufacturing hollow sections are typically made from mild steel or carbon steel. These materials offer excellent strength-to-weight ratio and are highly durable. Mild steel is commonly used due to its affordability and versatility, while carbon steel provides superior strength and resistance to impact.

The Manufacturing Process of Galvanized Hollow Sections

The manufacturing process of galvanized hollow sections involves several steps. First, the square tubes are cut to the desired length and shape. Then, they undergo a series of cleaning processes to remove any impurities or contaminants. Next, the tubes are immersed in a bath of molten zinc, where the galvanization takes place through a hot-dip process. Finally, the galvanized hollow sections are cooled, inspected for quality, and prepared for distribution.

Packaging Considerations for Square Tubes

Proper packaging is crucial to ensure the safe transportation and handling of galvanized hollow sections. Square tubes are carefully bundled and packed to protect them from external factors such as moisture, dust, and scratches. Packaging materials like plastic caps, wooden crates, or steel bands are used to secure the square tubes during transit, minimizing the risk of damage.

In conclusion, galvanized hollow sections offer a reliable and durable solution for various construction needs. With their superior strength, resistance to corrosion, and easy availability through wholesalers, galvanized hollow sections have become a go-to choice for engineers and builders. By understanding the manufacturing process, materials used, and importance of galvanization, one can make informed decisions and ensure the long-term performance of their structures.

Are galvanized hollow sections suitable for outdoor applications?

Yes, galvanized hollow sections are highly recommended for outdoor applications due to their excellent corrosion resistance.

Can galvanized hollow sections be custom-made to specific dimensions?

Yes, manufacturers can provide galvanized hollow sections in custom sizes to meet specific project requirements.

What are the advantages of using square tubes for hollow sections?

Square tubes offer better aesthetic appeal, ease of installation, and higher load-bearing capacity compared to other shapes.

How long can galvanized sections last before needing maintenance?

The lifespan of galvanized hollow sections can vary depending on environmental factors, but they can last for several decades with proper care.

Can galvanized hollow sections be welded?

Yes, galvanized hollow sections can be welded, but it is crucial to follow proper welding techniques to maintain the integrity of the galvanized coating.