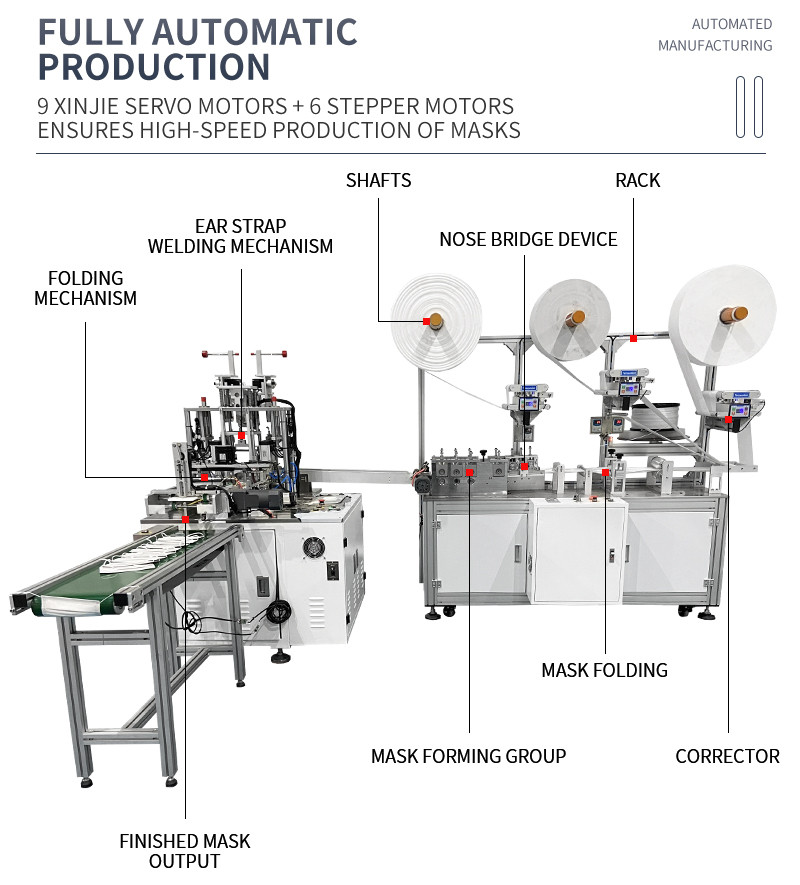

New upgraded steel panel 1+1 Automatic Face Mask Machine Details-9 Servo Motor-150~180PCS/MIN

group nameMask Machine

-

Min Order1 set

brand nameZQS

modelZQS-2009

payment methodWestern Union, MoneyGram, T/T

-

update timeFri, 09 Jun 2023 12:31:30 GMT

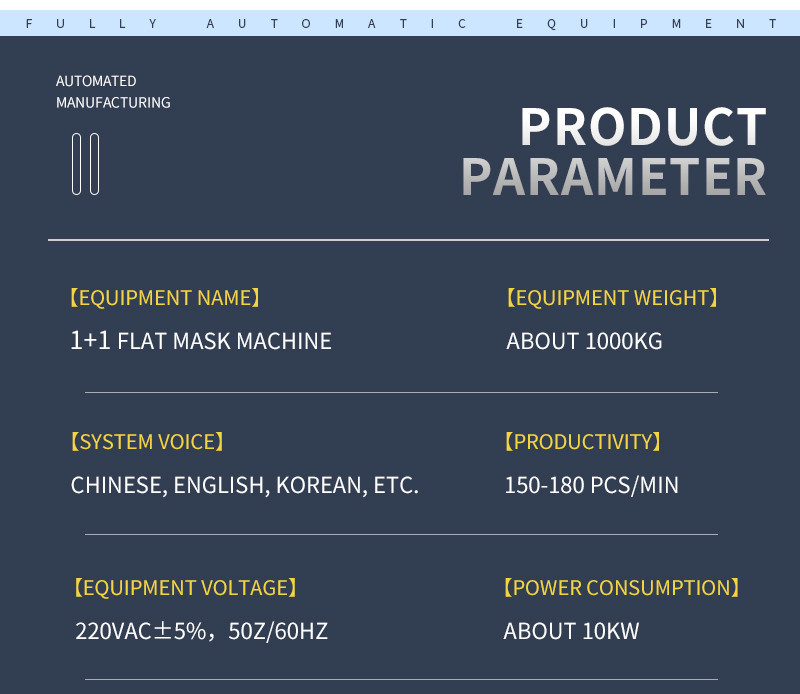

Paramtents

product name 9 servo motor fully automatic high speed face mask

Marketing Type New Product 2022

Core Components PLC

Automatic Grade Automatic

Voltage 220V

Dimension(L*W*H) 350x250x200cm

Weight 1050kg

Warranty 1 year except easy broken parts

After-sales Service Video technical support, Online support

Production Capacity 150-180pcs per min

Driver 9 Servo motors+6stepper motors

Ultrasonic digital

PLC brand Xinjie

Touch Screen Multi-Language

panel steel

Packging & Delivery

Size150cm x112cm x155cm

Weight1100kg / set

Min Order1 set

Briefing

Speed:150-180PCS/MIN

Features:9 Servo Motor

Mask type:Face、Medical、surgical、Dental

Detailed

Using PLC programming control, servo control, high degree of automation, high stability, low failure rate, low noise, high output, production efficiency of 70-100PCS/MIN;

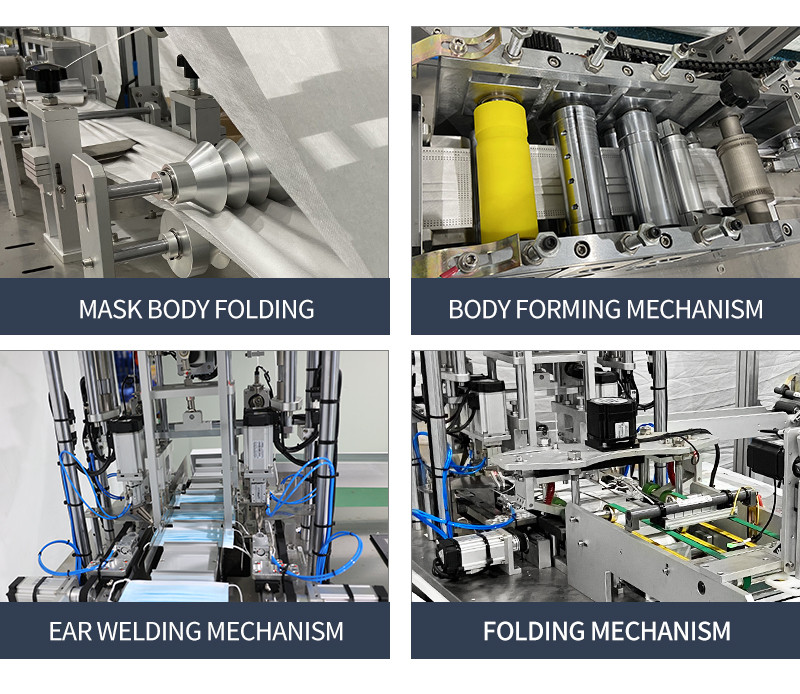

lA large number of servos are used to replace the cylinder action, which is efficient and rapid, reducing the impact on the machine;

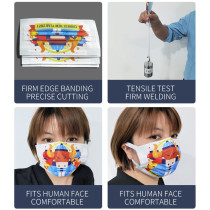

lUltrasonic welding ear straps, clear embossing, beautiful finished products, hygienic and environmental protection;

lThe whole production line is automatic operation from material feeding, nose line insertion, edge banding and cutting finished products, saving labor efficiently;

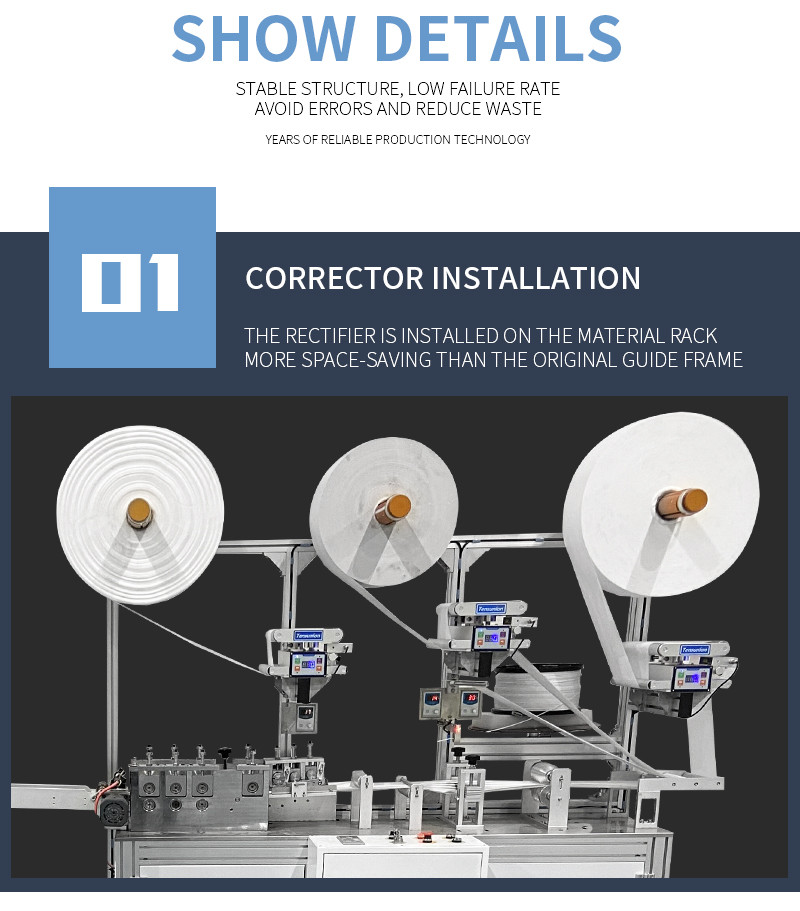

lEach action delay and position of the process have adjustable parameters, which can easily adjust the optimal product production line;

lEach process is independent into a module; if a module is not needed, it can be closed independently without re-modifying the program;

lIn automatic mode, it can be paused and started at any time; after the fault is suspended, it can be followed by production.

lPhotoelectric detection of raw materials to avoid mistakes and reduce waste; built-in alarm system, machine fault diagnosis function, system log function, equipment abnormality or lack of materials and its automatic shutdown alarm, screen guidance to quickly handle abnormalities;

You need a product

You May Like

6YRS Zhongshan Zhiqingsong Automatic Machinery Co.,Ltd

- Nearest port for product export

- GUANGZHOU, SHENZHEN, ZHONGSHAN, HONGKONG

- Delivery clauses under the trade mode

- FOB, CIF, EXW

- Acceptable payment methods

- T/T, MoneyGram, Westem Union, Cash