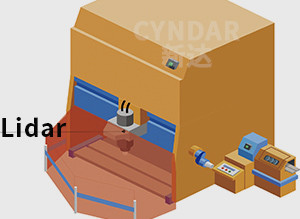

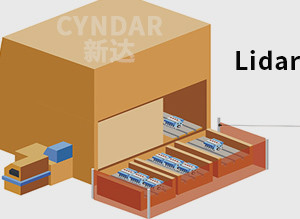

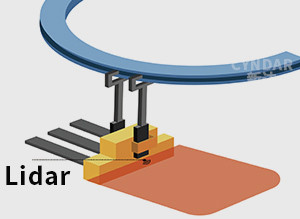

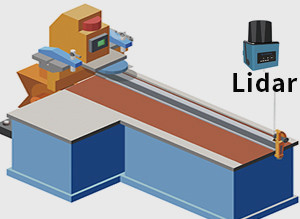

Lidar safety laser scanner sensor is used for cutting machine and bending machine protection

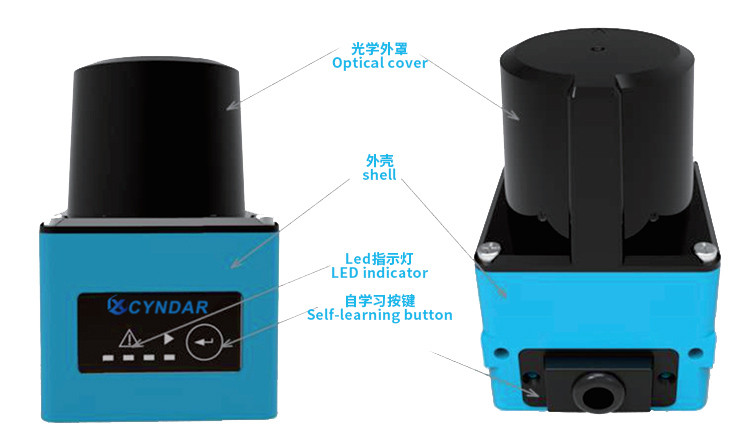

group name2D safety laser scanner sensor

-

Min Order1 piece

brand nameCYNDAR

modelXD-TOF-05D

payment methodT/T, Paypal

-

update timeMon, 01 Feb 2021 14:24:56 GMT

Paramtents

Ltem category safety laser scanner sensor area protection

Frequency of detection 15Hz/30Hz

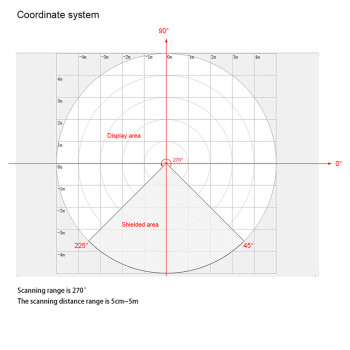

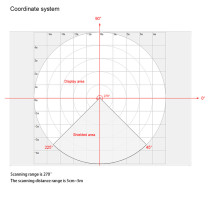

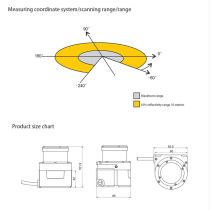

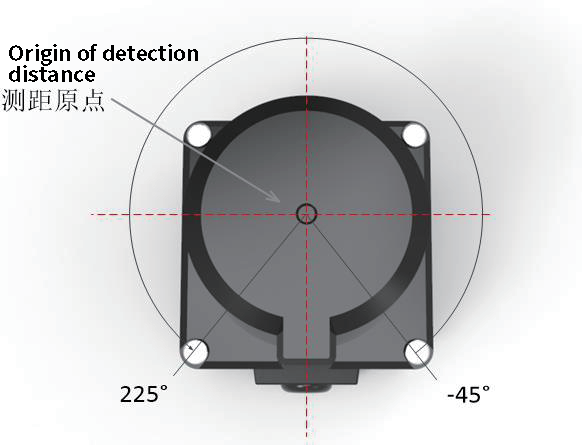

Detection angle range 270º

system error ±30mm

Work area 0.05m-5m

Range of working temperature 905nm(class I)

Packging & Delivery

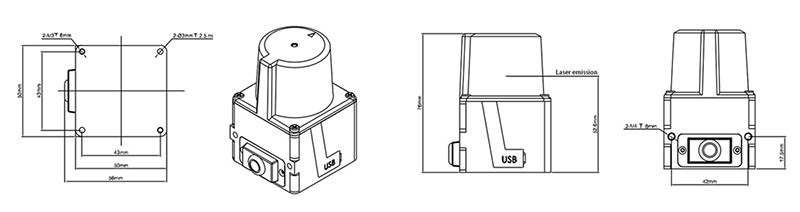

Size15cm x 15cm x 12cm

Weight1.00kg / piece

Min Order1 piece

Briefing

Detailed

series safety laser scanner

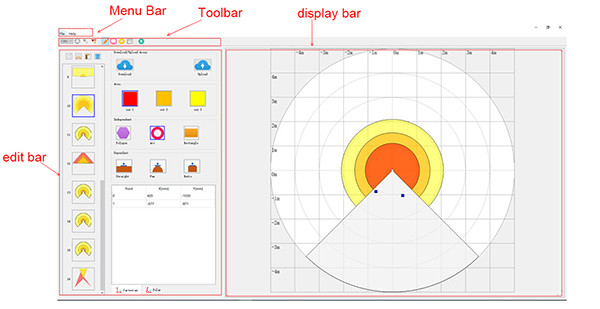

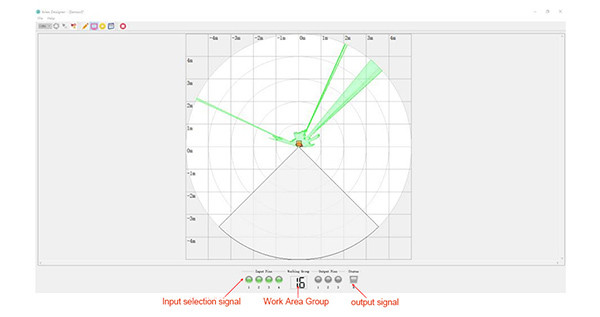

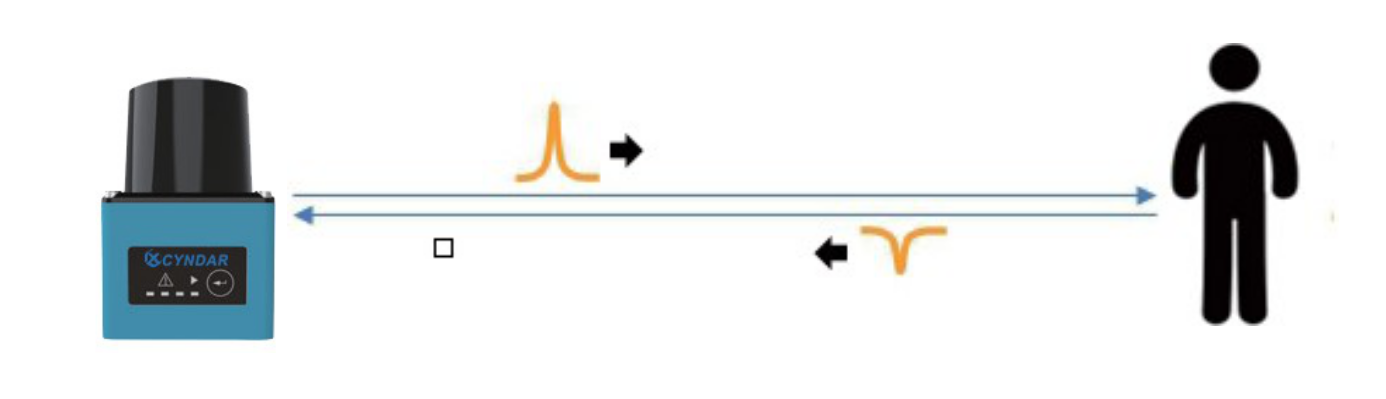

TOF-05D series safety laser scanner, the detection distance is up to 5 meters, the packaging line-paper cutter\cutting machine\punch machine peripheral personnel protection, angular resolution 0.1°, stable detection within 5 meters

You need a product

You May Like

6YRS GZ Cyndar Co., Ltd

- Delivery clauses under the trade mode

- FOB, EXW, Express Delivery

- Acceptable payment methods

- T/T, PayPal