Ringlock Scaffolding Vertical Standard Parts Supplier

group nameScaffolding

-

Min Order1 piece

brand nameBAOLAI Steel Pipe Wholesale Manufacturer

modelRinglock Scaffolding Vertical Standard Parts

payment methodT/T, L/C, D/P D/A, Westem Union

-

update timeThu, 08 Dec 2022 10:22:29 GMT

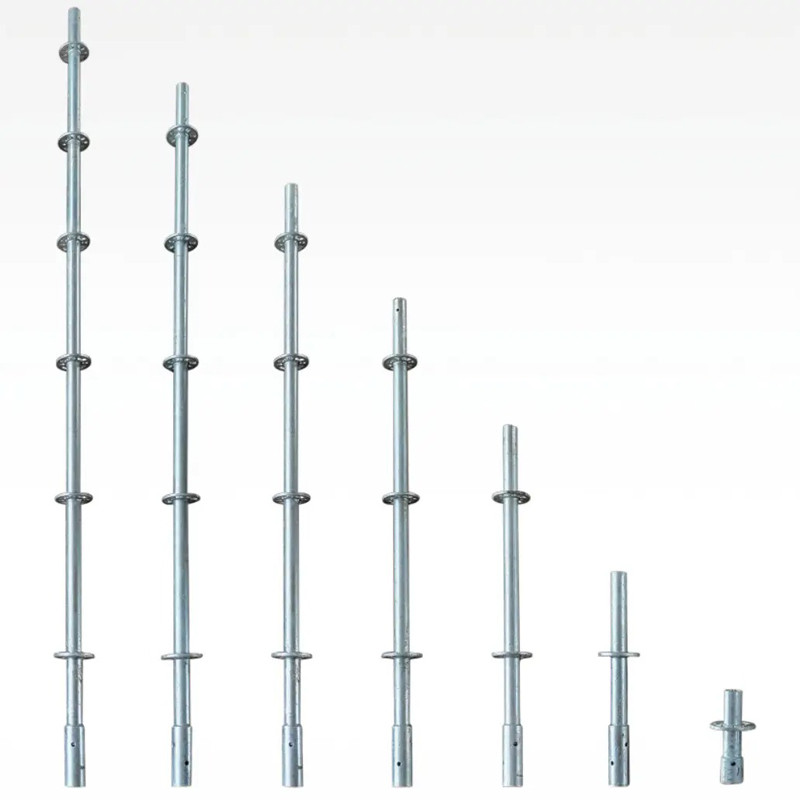

Paramtents

OD 48.3 mm

Material Q235/ Q345

Wall Thickness 3.0 - 4.0 mm

Length 0.5 - 3.0 M

Surface Red/ Yellow /Hot Dipped Galvanized

Joint 38 x 4.0 x 270 mm (0.9kg)

Usage Building construction/ Mining sector/ Grandstands

Packging & Delivery

Min Order1 piece

Briefing

Detailed

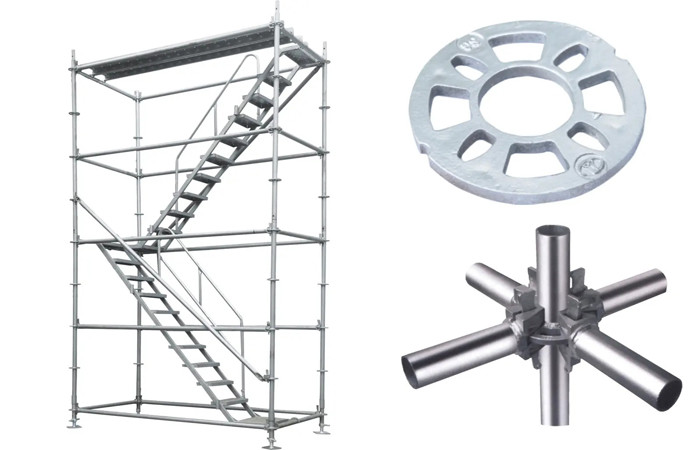

- √Versatility

- Ringlock Scaffolding can form different sizes, shapes and different load-bearing capacities can be single/double scaffolding, support structure or support pole according to the construction instruments.

- √Heavy load-bearing capacities

- The connection between vertical pipes is in the same axes center, the connection is within the same square, the connection is anti-bending, shear resistance and torque resistance, the material is Q345, stable structure, and heavy load capacities.

- √High Quality

- The Ringlock Scaffolding is automatically welded by machine, full-body by hot-dip galvanized, long life span.

- √High Efficiency & Cost-effective

- Lightweight, simple structure, low maintenance, low cost,easy to set up and demolish, avoid loss of screws work and small clamps, the speed to form connections is 5 times faster than normal scaffoldings, and a worker can finish all the assembling by a hammer, also it can be lifted as a whole structure to save time and shorten the schedule

Specification (OD) | Wall Thickness |

Length

|

Weight

|

mm | mm |

mm

|

KG

|

48.3 | 3.0 - 4.0 | 0.5 | 2.25 |

48.3 | 3.0 - 4.0 | 1 | 4.51 |

48.3 | 3.0 - 4.0 | 1.5 | 6.76 |

48.3 | 3.0 - 4.0 | 2 | 9.02 |

48.3 | 3.0 - 4.0 | 2.5 | 11.27 |

48.3 | 3.0 - 4.0 | 3.0 | 13.53 |

Joint | 38 x 4.0 x 270 | 0.9 | |

Note: The theoretical weight of the pole is thickness 3.25mm. | |||

- √OEM & ODM

- √Protective Coatings

- √Saw and Flame Cutting

- √Calculate total volume and weight

- For more information, please contact our service team.

You need a product

You May Like

- Nearest port for product export

- TIANJIN

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, DDP, DDU

- Acceptable payment methods

- T/T, L/C, D/P D/A, Westem Union