Combination Decoiler Straightener Feeder Machine for 0.2~3.2mm Thickness Steel Coil Handling Solution

group nameDecoiler Straightener Feeder

-

Min Order1 piece

brand nameFANTY Steel Coil Handling Equipment Manufacturer

modelDSF1 Series Combination Uncoiler Straightener Feeder for 0.2~3.2mm Coil Steel High Speed Stamping

payment methodL/C, Western Union

-

update timeSat, 27 Apr 2024 19:46:46 GMT

Paramtents

Color Standard white (other colors are available)

Payment 30% T/T as deposit, rest against shipping

Customized Service Yes

Certificate ISO, CE

Packging & Delivery

Min Order1 piece

Briefing

Detailed

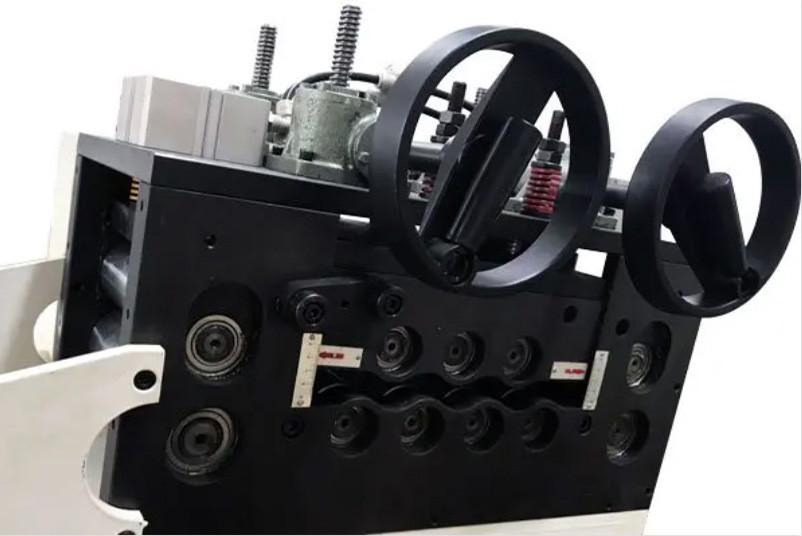

The DSF1 3-in-1 decoiler straightener feeder combines material rack, leveling, and feeding into one compact unit. One person handles all of the feeding, feeding, blocking, folding, leveling, feeding, and changing. Point-controlled operation on a separate console can be used to complete it, which significantly reduces labor costs, effectively resolving the issue of uncoordinated leveling and feeding, and enabling high-speed leveling and feeding. The entire appearance is both powerful and stunning.

The device uses a bottom-feeding technique that can punch, uncoil, and level feed medium and thin plate coils with a thickness of 0.2mm to 3.2mm and a width of 50mm to 400mm. The feeding pressing plate works in tandem with the pressing arm to flatten the material head so that it may enter the machine smoothly. This prevents the coil material from becoming loose.

Model | DSF1-300 | DSF1-400 |

Stock Width(mm) | 50~300 | 50~400 |

Stock Thickness(mm) | 0.2~3.2 | 0.2~3.2 |

Max.Coil Weight(kg) | 3000 | 3000 |

Max.Coil O.D.(mm) | 1200 | 1200 |

Coil I.D.(mm) | 508 | 508 |

Feed Length(mm) | 400 | 400 |

Max.Line Speed(m/min) | 16-24 | 16-24 |

Work Roll Number | upper4/down3 | upper4/down3 |

Feed Roll number | 1 | 1 |

Main Motor(kw) | AC2.0 | AC2.0 |

Mandrel Expansion | By manual (pneumatic) / hydraulic | By manual (pneumatic) / hydraulic |

Reel Motor(kw) | 1.5 | 1.5 |

Power (V) | 3Phase 220V/380V/50HZ | 3Phase 220V/380V/50HZ |

Operating Air(Mpa) | 0.49 | 0.49 |

Fanty machinery focus on the domestic market of punch press automation equipment production and sales from 2013. The field including domestic hardware industry , automotive stamping line, auto metal stamping part, saw blade production, high speed rotor and stator stamping and lamination, eyelet stamping line and so on.

We provide high quality uncoiling, leveling, feeding and punch equipment to help many local factories realize the importance of automation production, and more and more factories upgrade and improve their metal stamping line. Fanty machinery has exported machine to more than 30 countries. MORE

DSF1 series combine uncoiler leveler feeder for 0.2~3.2mm thickness

DSF2 series combine uncoiler leveler feeder for 0.5~4.5mm thickness

DSF3 series combine uncoiler leveler feeder for 0.6~6.0mm thickness

Customization

1) We can record the testing video for your reference about thin plate decoiler straightener feeder machine.

2) You are welcome to visit us and test machine in our factory.

We provide technical support on line as well as overseas services by skillful technicians.

We can make OEM & ODM with customers. We provide and construct each project to individual customer's needs. All of our machine can be custom made based on reasonable requirement.

You need a product

Related Searches

You May Like

- Nearest port for product export

- shekou, shenzhen

- Delivery clauses under the trade mode

- FOB, CIF, EXW

- Acceptable payment methods

- T/T