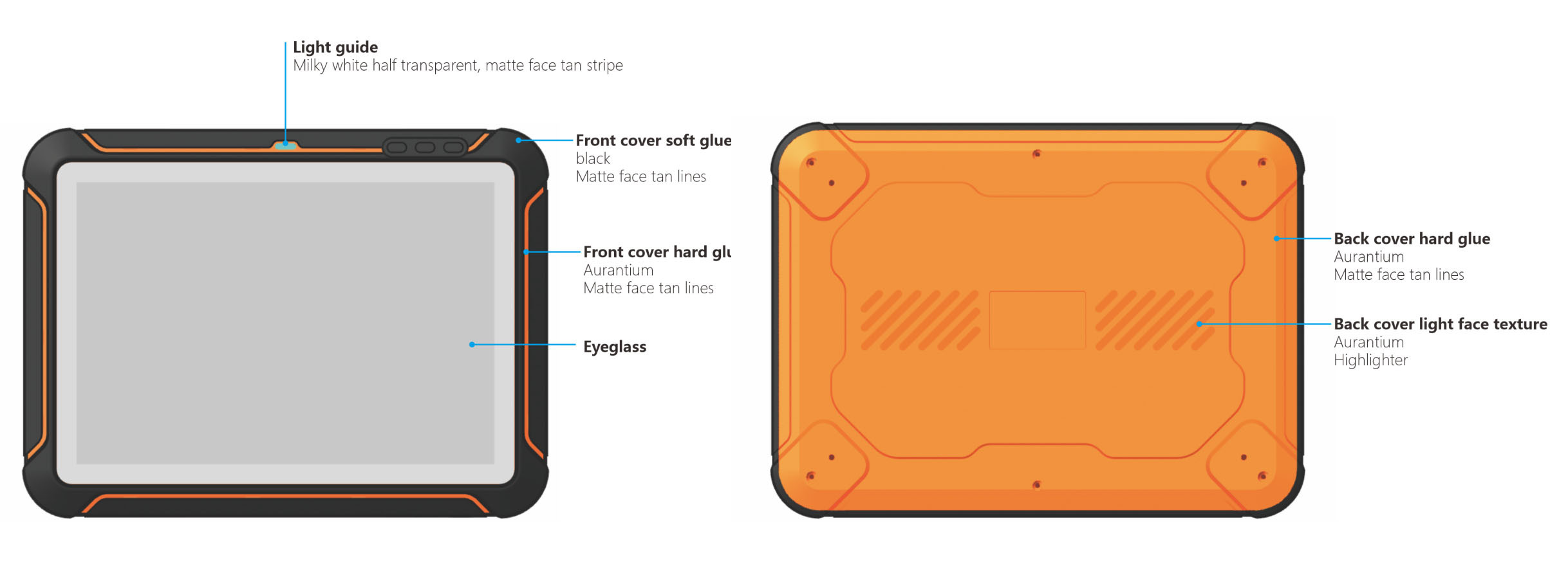

10.2 inch Warehouse E-ink Electronic Label Low Power Pick to Light and Put to Light Systems

SETP_Label_V102 is a 10.2-inch electronic paper tablet specifically designed for warehouse picking and factory workflow displays. This device offers a robust IP66 waterproof rating, making it ideal for various industrial environments where durability and reliability are essential.

The SETP_Label_V102 operates on an energy-efficient electronic paper display that not only conserves power but also eliminates the need for traditional paper, resulting in significant cost savings for businesses. With its seamless connection to the SETP_Router_V1.4 base station, users can effortlessly update display information with just a single click, streamlining operational processes.

The SETP_Label_V102 is the perfect solution for modern logistics and manufacturing, designed to enhance operational efficiency and deliver reliable performance in challenging environments.

The Base Stations of Pick-to-Light

This allows it to

receive button feedback from the Pick to Light electronic labels while sending data to them.

Features: Equipped with a built-in server program for effortless data transmission.

Ease of Use: Users simply send operational instructions directly to this base station for efficient data transfer, ensuring user-friendly functionality.

10.2 inch Warehouse E-ink Electronic Label Advantage

● Paperless EfficiencyUtilizing advanced electronic paper technology, the SETP_Label_V102 eliminates paper waste, reducing material costs and supporting eco-friendly practices.

● One-Click Updates

Instantly modify all incoming material information with a user-friendly interface, significantly cutting down on labor costs and time spent on updates.

● Streamlined Workflows

This tablet optimizes critical tasks such as information updates, display changes, and picking processes, leading to increased productivity and efficiency in operations.

● Customizable LED Indicators

Equipped with multi-color LED lights, the SETP_Label_V102 allows for easy identification of different goods by programming specific colors for various items, enhancing operational clarity.

● Lower Error Rates

By providing accurate information displays, the device helps minimize human errors and ensures higher accuracy in picking and workflow management.