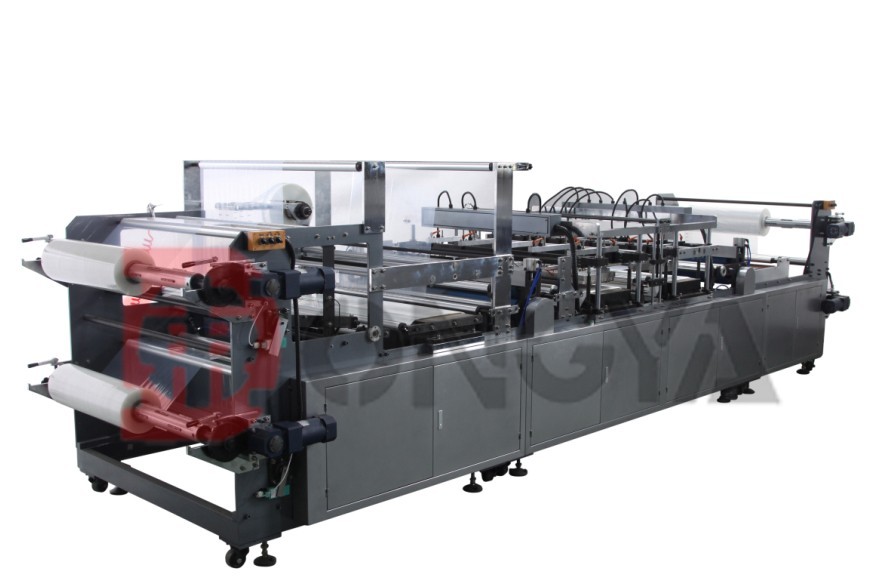

buffer column bag forming machine

- US $40000.00

1 - 2 piece

group nameAir column bag making machine

-

Min Order1 piece

brand nameVinot

modelDY-800 ( bag piece by piece)

payment methodL/C, T/T

-

update timeWed, 01 Nov 2017 16:40:50 GMT

Packging & Delivery

Size500cm x 320cm x 178cm

Weight2800kg / piece

Min Order1 piece

Briefing

Detailed

Cushion Air Column Bag Forming Machine DY-800

Bag piece by piece

This production line uses PE/PA co-extruded film and the air valve film to weld air column sheet film and the air valve film to weld air column sheet first, then fold the air column sheet to the desired bag pattern, and then seal and cut to get the finished air column bags. Wide range of bag patterns can be achieved by this line such as Q bag, U bag, Cap, Pad, etc., for different cushion packaging requirement. Promivision fully automatic high speed air column bag production line boasts high efficiency, versatility and flexibility.

Cushion Air Column Welding Machine Model DY-1200

Technical Parameters:

Bag Making Parameters: Realized by PCL control panel for setting pressing time, pressing temperature, standards compensation, roll-unwinding, automatic variation correction system

This production line uses PE/PA co-extruded film and the air valve film to weld air column sheet first, then fold the air column sheet to the desired bag pattern, and then seal and cut to get the finished air column bags. Wide range of bag patterns can be achieved by this line such as Q bag, U bag, Cap, Pad, etc., for different cushion packaging requirement. Promivision fully automatic high speed air column bag production line boasts high efficiency, versatility and flexibility.

Core Benefits of Cushion Air Column Bags

1 5 or 7 layer PE/PA co-extruded film deliver high strength and superior airtightness, which ensure the optimum cushion performance of the air column bags.

2 Wide variety of bag patterns such as Q bag, U bag, Cap, Pad, Roll, etc, can meet every cushion packing requirement.

3 The bag utilizes one-way air valve, which enables all the columns of the bag to be inflated sinmultaneously, and the air will be locked inside the columns.

4 If one column of the bag is broken or torn, the other columns will remain intact, as each column is independent.

You need a product

- Nearest port for product export

- Ningbo, Shanghai

- Acceptable payment methods

- T/T, L/C, Westem Union, Cash