2018 Vinot Top Quality High Speed Monolayer Blown Film Machine HDPE or LDPE taked as raw material Model No.SJ-45M

group nameFilm Blowing Machine

-

Min Order1 piece

brand nameVinot

modelDYSJ-YT-45

payment methodL/C, T/T, Western Union

-

update timeFri, 12 Jan 2018 17:00:09 GMT

Paramtents

Color Red

Be applied to Machinery industry

Condition New

Automatic Yes

Application Film

Voltage 380V

Packging & Delivery

Min Order1 piece

Briefing

Detailed

2018 Vinot Top Quality High Speed Monolayer Blown Film Machine HDPE or LDPE taked as raw material Model No.SJ-45M

| Screw Diameter: | 45mm | L / D Ratio: | 30 : 1 |

|---|---|---|---|

| Film Thickness: | 0.01 - 0.10mm | Film Width: | 100 - 600mm |

| Heating Power: | 11kw | Max Output: | 40kg / H |

| Model No.: | SJ-45M Or DYSJ-45M | Reduced Diameter Of Film: | 100-600mm |

| OVERALL SIZE: | 2.6x1.9x3.5m | Weight: | 1.5T |

| Power Of Main Motor: | 11 Kw |

High Speed Full Automatic Plastic Mini

Model No.DYSJ - 45M

Film Blowing Machine

Feature:

The machine take the HDPE or LDPE as raw material,through heating,extrusion,blowing,stretch,winder and final be roll thin film.The finished plastic thin is widely used for supermarket bag, garbage bag,various plastic package bag.

Optional Device: Auto loader

Air shaft

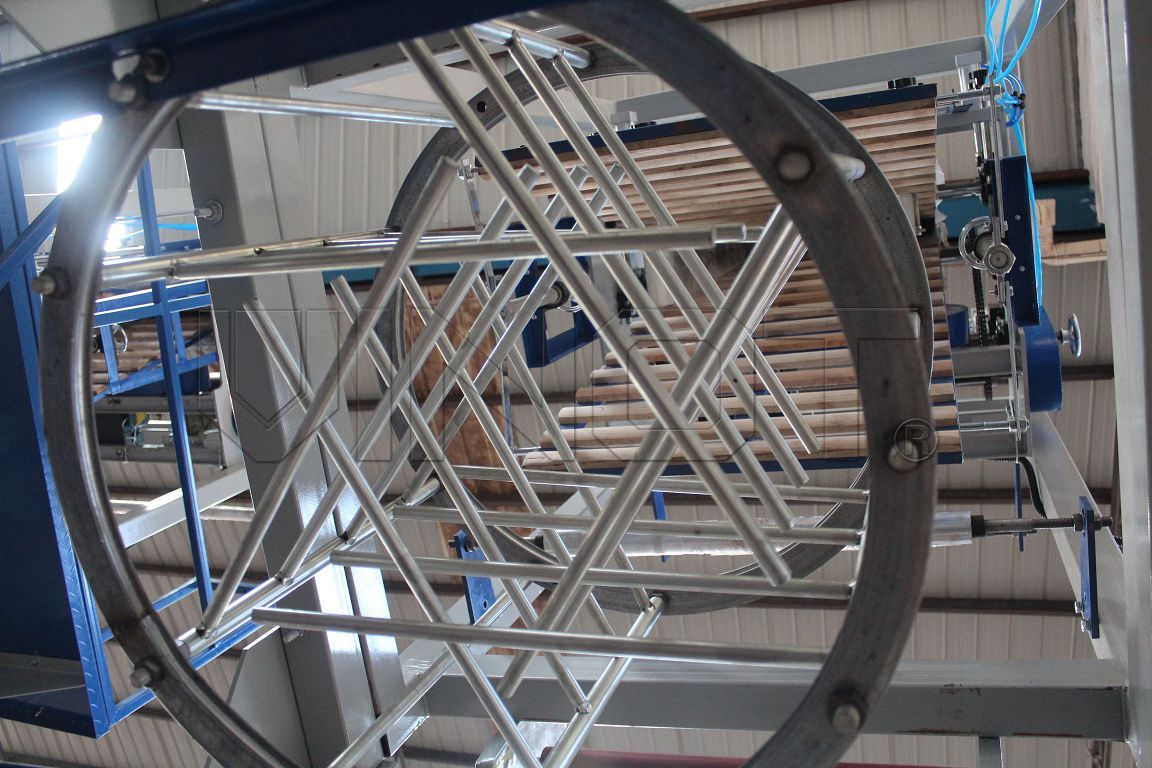

Rotary Die

Advantages:

♦ The mini film blowing machine’s barrel and screw rods are all made of quality alloy steel that have been nitrided and processed by precision machining equipment.

♦ Hence it is sound in hardness, durable in corrosion resistance.

♦ The specially-designed screw is of sound quality In plasticizing, which helps increase the production capacity

♦ It is applied to blowing the plastic films of low density polyethylene (LDPE) or high density polyethylene (HDPE) or linear low density polyethylene(LLDPE).

♦ It is widely applied to producing the packing bags for foodstuff, clothing, rubbish bag and vest bags.

♦ Coiling unit adopts torque motor to keep proper tension, winding smoothly, and convenient to change the coil.

♦ The machine body is made of square steel, equipped with frequency converter to control traction motor, friction style winding and elevating, which is suitable for blowing HDPE/LDPE industrial and agriculture film.

♦ It can be used for continuously printing various plastic films, cloths, thin leather and package products etc, one-sided or two-sided printing finished by once-through operation.

♦ 360 degree register sets is accurate and doesn’t affect stretching film, and the color registration can be adjusted freely.

Main Specification:

| MODEL | SJ-45M |

| SCREW DIAMETER(mm) | Φ45 |

| REDUCED DIAMETER OF FILM | 100-600mm |

| FILM THICKNESS | 0.01-0.10mm |

| MAX.EXTRUSION OUTPUT | 40kg/hr |

| SCREW L/D | 30:1 |

| POWER OF MAIN MOTOR | 11KW |

| POWER OF TRACTION MOTOR | 0.75KW |

| HEATER POWER | 11KW |

| OVERALL SIZE | 2.6x1.9x3.5m |

| WEIGHT | 1.5T |

Details Picture :

You need a product

You May Like

- Nearest port for product export

- Ningbo, Shanghai

- Acceptable payment methods

- T/T, L/C, Westem Union, Cash