Sauce Pickled Vegetables/Fruits Filling Line

group namePre-made Pouch Packaging Machinery

-

Min Order1 piece

brand nameREZPACK

modelRZ6-200J

payment method

-

update timeTue, 19 Nov 2013 17:00:38 GMT

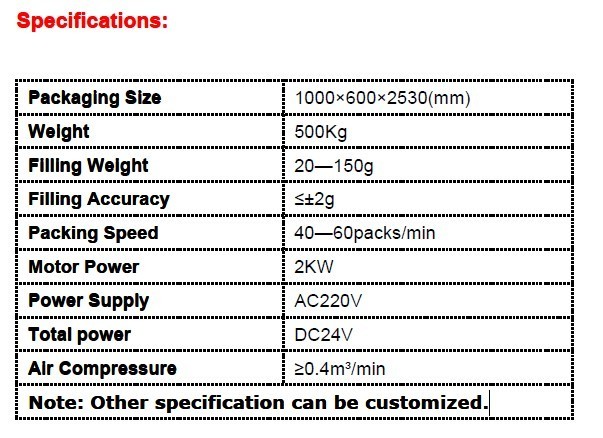

Paramtents

Packing material Pickled vegetable, furit jam, reserved vegetable

Packing Container glass bottle, compond bag

Advantage High hygienic Construction,GMP standard

Applied Products Pickled Food with oil liquid

Packging & Delivery

Min Order1 piece

Briefing

High Gienic Construction, GMP standard, high accuracy

Detailed

Main Features

1. Special for pickles weighing and filling.

2. This line replaces the manual packing help the large-sized enterprises, medium-and small sized

enterprise realize automatic packing and thus improve the industrial production effective and reduce

the costs.

3. The filling machine combines auger measure and cup measure together, and reach more accurate

accuracy.

4. With different sauce or oil filling is possible.

5. The packing machine has the function of no bottle/no bag no filling,

6. PLC intelligence control system can precisely control the filling.

7. It conforms to the hygienic standard of foodstuff processing machine. All the spare parts for the

machine touching the raw materials are made of stainless steel 316#.The packed foodstuff is of

healthy and security.

8. The machine has the function of material vibration.

9. The machine transmission helps the packing equipments produce stably and reduce the trouble

occurrence.

Main Machine Items:

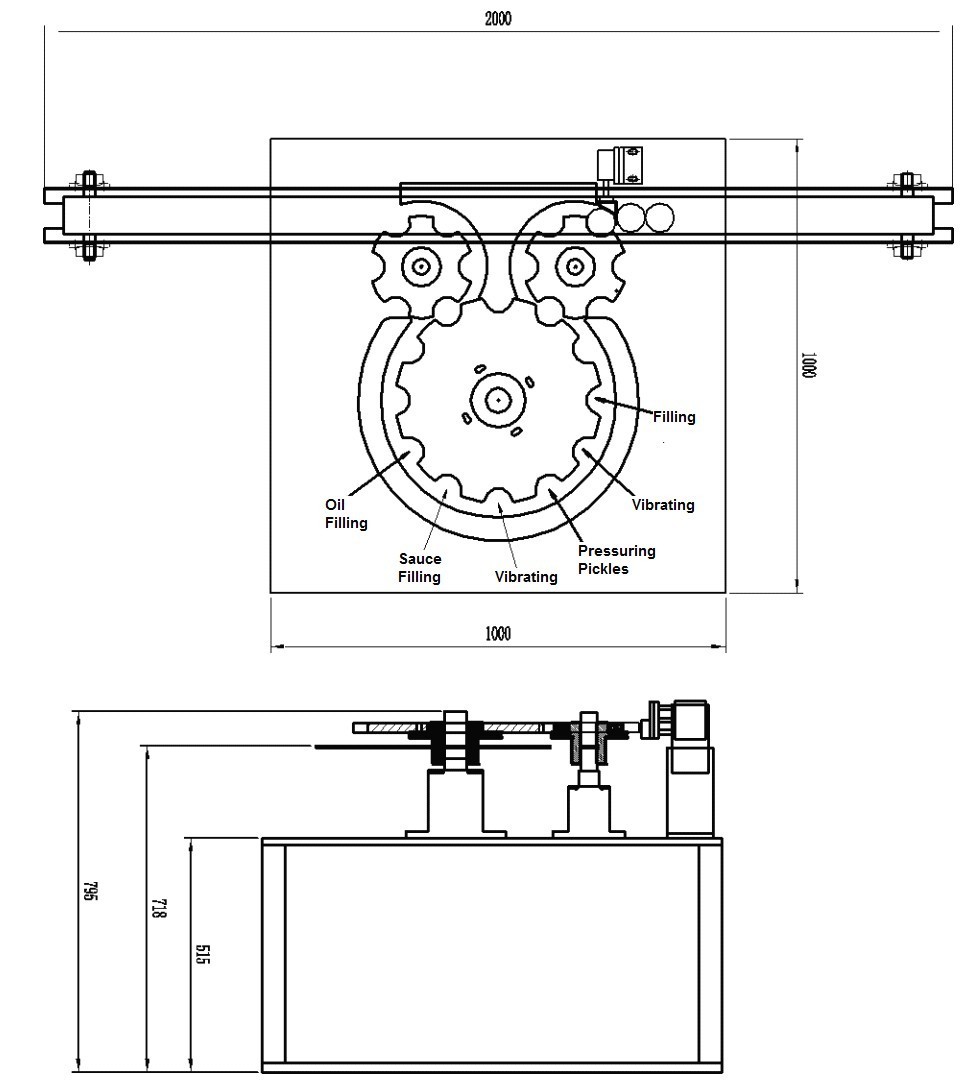

Pickles Weighing Filling Machine

Speciality

Full automatic metering scale for sauce pickled vegetables replaces manual work.

Suits for weighing all kinds of pickles, including pickled mustard tuber, day lily, dried radish, ginger

slices, sauce pickled vegetables, jellyfish, fish sauce, etc.

Easy to operate,PLC controller and touch-screen, fault indication on the touch screen.

Easy to Clean, the hopper can be opened for easy cleaning.

Combines auger measure and cup measure together, so more accurate accuracy.

Hygienic construction, the product contact parts are adopted stainless steel

Bottle Filling and Packing Machine

Main Features:

The machine has the function of no bottle no filling.

PLC intelligent control system can precisely control the filling.

All material meet the food processing machinery & food hygienic standard requirements.

The machine has the function of material vibration and pressure.

Stable mechnical performance insures the lowest trouble occurence.

Station 1 Bag dispensing (Bag feeding)

Vertical bag feeder or horizontal bag feeder for option.

Station 2 Coding (Date Printing)

Ribbon printer, Ink-jet printer or others for optio.

Station 3 Bag Opening

To ensure the bag opened enough. If the bag is with zipper, 8 station will be

needed.

Station 4 Filling

Measured and filled by Pickles Filler.

Station 5 Sauce Filling

For sauce or oil filling if need, by sauce or liquid filler.

Station 6 Sealing and output

Hot sealing to make sure strong sealing, and then output the finished production

automatically. (the sealing patter with net or straight lines for your option)

Packing samples

Working Layout