Automatic bag making weighing granule packing machine

group namebag filling and sealing machine(Packing Machine)

-

Min Order1 piece

brand nameDONGTAI

payment methodT/T, L/C

-

update timeMon, 10 Dec 2018 15:43:05 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

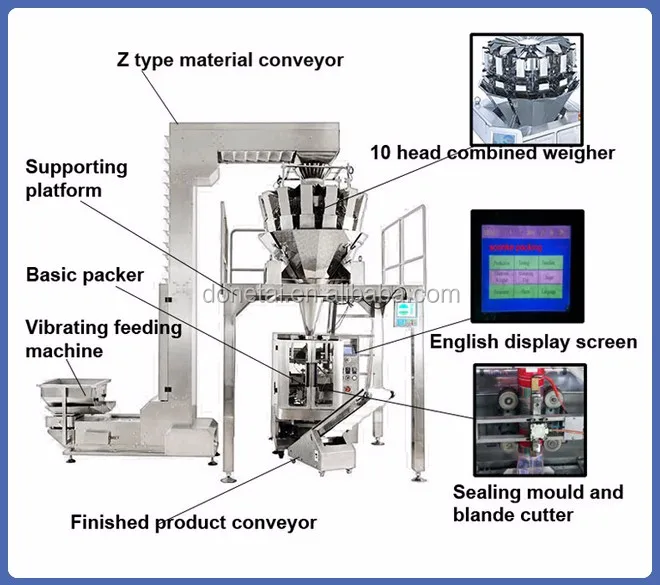

granule packing machine---Introduce

The combination weighing particle packing machine is suitable for packaging extruded food, candy, frozen class, pet food, hardware and other irregular granular materials, such as potato chips, rice crust, walnut, pistachio, candies, melon seeds, plum, peanut, chocolate, nuts, and other granular, ball, bar and block

automatic granule packing machine---Features

1. The combined weighing particle packaging machine has a series of automatic functions, such as automatic feeding, measuring, bagging, filling, sealing, printing date and finished product output.

2. The machine adopts high precision servo film transport system, PLC program control, touch human-machine interface of advanced automatic positioning, photoelectric tracking, digital temperature control, etc., so the operation is more simple, perfect, is the food packaging industry to improve the production efficiency, reduce labor intensity, improve the grade of packaging equipment of choice.

3. The device can adjust the opening and closing speed of the hopper door according to the characteristics of the measured objects to prevent breakage and card material.

granule sugar packing machine---Parameter

| Product name | Automatic bag making weighing granule packing machine |

| Material | stainless steel |

| Volume | 150-1200g |

| Packing speed | 5-60bags/min |

| Power | 220V/380V |

| Rate Of Work | 2.2kw |

| Machine Dimension | 1320*950*1360mm |

| Package | wooden case |

Iorder to ensure product quality, all suppliers of raw materials, electrical components, and industrial automation that strictly control all aspects of circulation are from well-known brands at home and abroad. They must be strictly inspected by quality inspectors before entering the warehouse. Use, product production is completed, from the assembly plant into the commissioning workshop, after a number of rounds of precision and speed test, after commissioning can be allowed to leave the factory.

1. Cover by PVC film + fumigated wooden case;

2. Wooden case suitable for long distance ocean shipping.

1. Technical support online service provided.

2. Technical files service provided.

3. On-site training service provided.

4. Spare parts replacement and repair service provided.

You need a product

Related Searches

You May Like

- Nearest port for product export

- Qingdao, Dalian, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C