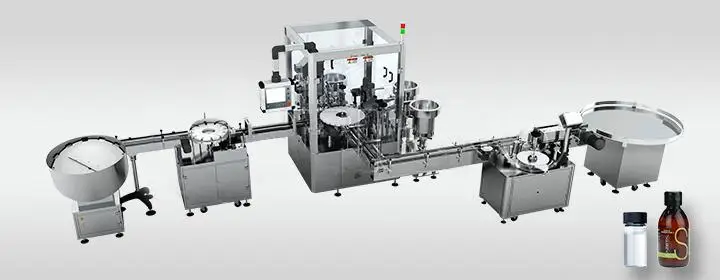

Automatic eye drops / perfume vials washing filling and capping machine

group nameView all custom machinery

-

Min Order1 set

brand nameDONGTAI

modelDTL-17F

payment methodT/T, L/C

-

update timeThu, 10 Jan 2019 11:02:33 GMT

Paramtents

Filling volume 25-200ml

Filling speed 2500-3000pcs/h

Material viscosity ≤7000cp

Air pressure 0.6~0.8Mpa

Voltage 380/220V (Optional)

Packging & Delivery

Min Order1 set

Briefing

Detailed

Automatic eye drops / perfume vials washing filling and capping machine

Samples:

Brief Introduction:

This equipment has higher requirements for customers, and has increased the bottle

handling device,the internal stopper station, the flushing device, and some detecting

devices. Filling for multi-head filling(dosage is generally 25-200ml)

Device contains:

1.Automatic bottle unscrambler

2.One automatic filling and capping machine (can be added with air pump)

3.One labeling machine

4.One bottle collector

Here is Liquid filling machine,If you want dry syrup Powder Filling machine,we

have both,please give us your valuable enquiry,we will reply you soon.

Technical parameters:

Scope of filling | 25~200ml |

Capacity | 2500~3000 Psc/h |

Filling precision | ±1.5% |

| Material viscosity | ≤7000 cp |

| Air Pressure | 0.6~0.8MPa |

Power Supply | 380/220V (Optional) |

Functions:

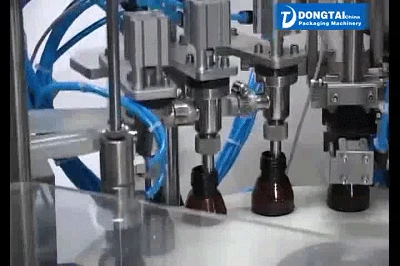

1.automatic bottle arranging, filling, plugging, cap screwing, labeling. It is equipped with

automatic internal plug arranging and external cap pluging testing which enables non-

external pluging without internalplug and elimination of non-external plug.

2.The labeling adopts belt rolling structure with fast rolling structure and 8-D adjustment of

angle label, which realizes the labeling of two symmetric labels or high-precision labeling.

|  |

| automatic bottle arranging | automatic filling |

|  |

| automatic plugging, cap screwing | automatic labeling |

Warming welcome your inquiry for our liquid filling capping machine~!

Q: How long will take for the delivery of product?

A: 7 days for standard model, if machine in stock, will delivery immediately, customized

model depend on customer requirements, usually about 30 days.

Q: What’s the insurance of after-sale service after purchase?

A: All our products, will be totally tested by QC department before delivery, with strict

quality control process. The product is cost-effective during use, stable and reliable.

One year warranty service for all machine, please feel free to contact us if you have any

questions.

Q: When the machine arrives at the work site, is it easy to install? How to solve

the problem of quick installation and use?

A: All machine model with installation video, to show the installation process more

intuitively, and we will provide remote video technical support to solve your doubts and

ensure that your installation is correct.

Install video URL: https://..........com/groups/1644623782523083/

https://..........com/channel/UC_wUu5QTxgZsfGRzgxxK29w?view_as=subscriber

(FOLLOW US ON YOUTUBE, TO SEE MORE ABOUT US)

After-sales appointment installation service phone :

+8618560751875 86-531-88168830 engineer Zhang

Q: During the use of the machine, how to get after-sale service?

A: We have professional foreign installation and commissioning engineers, which have

many years of experience in foreign debugging with deeply recognized by customers. We

will provide on-site installation and commissioning services for foreign customers, and we

will guide your workers directly.

Q: Will the accessories change frequently with machine ?

A: The service life of the accessories is related to the daily maintenance. When ordering,

we will give you free wearing parts and provide you with daily maintenance strategies.

You need a product

You May Like

- Nearest port for product export

- Qingdao, Dalian, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C