Plastic Cup Thermoforming Machine (FJL-660SB Series )

group nameThermoforming Machines

-

Min Order1 piece

-

update timeFri, 23 Dec 2011 23:49:14 GMT

Packging & Delivery

Min Order1 piece

Briefing

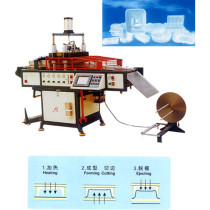

FJL-660SB Series Fully-Automatic Plastic Thermoforming Machine is used to produce disposable water drinking cups,

Detailed

FJL-660SB Series Fully-Automatic Plastic Thermoforming Machine is used to produce disposable water drinking cups, ice-cream cups, disposable cup/bowl for yoghurt, lids, dishes, plates and etc.

Major Construction Features:

FJL-660SB Series Automatic Hydraulic Cup Making Machine is new equipment, which has been developed and produced with many years of machine producing experiences of our company, it uses stable hydraulic system and pneumatic technology to control together, its operation is stable, noise is small, mold locking ability is strong and quality is high. It mainly consists of formed machine, material rack, material receiving machine and screen controlled by electricity.

1. The machine is completely automatic, productive speed is fast. Different products can be produced with different molds.

2. It uses import famous brands of electric and pneumatic fittings, so the operation is stable, quality is reliable and life is long.

3. The design of the mold is advanced and special, heat the thermoplastic plastic flake board and put on the mold, pull the piston, give the pressure to the air, keep the flake board close to the inside of the mold to form, then, cut and automatically blow the product. The structure of the whole machine is compact, one mold has all the functions, like pressure giving, forming, cutting, cooling, and finished product blowing, so the process is short, quality of the finished product is high and matches with national sanitary standard.

Main Technical Parameter

|

Model |

FJL-660SB-A |

FJL-660SB-B |

FJL-660SB-C | ||

|

Material Used |

PP、HIPS、PE、PS、PET、PVC Sheet Roll | ||||

|

Sheet Width |

300-660mm | ||||

|

Sheet Thickness |

0.2-2mm | ||||

|

Forming Speed |

15~30moulds/minute | ||||

|

Forming Depth |

≤125(mm) | ||||

|

Max. Sheet Roll Dia. |

700mm | ||||

|

Max.Forming Area |

650×220(mm) |

650×220(mm) |

650×320(mm) | ||

|

Main Motor Power |

7.5KW |

7.5KW |

15KW | ||

|

Overall Power |

≤66KW |

≤66KW |

≤76KW | ||

|

Working Air Pressure |

0.6~0.8MPa (1.6m³/min) | ||||

|

Overall Dimension |

3.15×1.5×2.3(m) |

3.4×1.6×2.3(m) |

3.4×1.6×2.3(m) | ||

|

Approx.Weight |

4100Kg |

4200Kg |

4300Kg | ||

|

Power Supply |

380V/50HZ, Tri-phase, Four-wire | ||||