pouring silicone rubber (HY620# HY640# )

- US $12.68

100 - 40,000 kilogram

- US $6.98

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order100 kilogram

brand nameHong Ye silicone rubber

modelpouring silicone rubber HY620# HY640#

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 11:25:05 GMT

Paramtents

Certificated RoHS, Reach , MSDS , SGS , ISO9001:2000

Color white

shape liquid

Package Vacuum pumping package

shelf life 12 months

mixing ratio 100:3

operation time 30-40 mins

curing time 3-4 h

operation way brushing, pouring

MOQ 200 kg

Packging & Delivery

Min Order100 kilogram

Briefing

1 Easy Operation

2 Resistance to deformation

3.Low shrinkage

4.Large reproduction time

Detailed

|

[1] application of pouring silicone rubber (HY620# HY640# )

pouring silicone rubber (HY620# HY640# ) is mainly applicable to make the silicone mould for cultural relic duplication,architectural decoration, silicon rubber can be usedf for resin crafts, lighting ornaments, candles, statues, RTV pouring silicone can also be used for molds design, product exploitation, etc.

[2] features of RTV molding silicone rubber for plastic/gypsum:

pouring silicone rubber (HY620# HY640# ) is generally named two -component room temperature vulcanization silicone rubber, a kind elastic silicone rubber mold which features with resistance to deformation, high-temperature, acid-alkali and expansion.

[3]instruction of pouring silicone rubber (HY620# HY640# ):

pouring silicone rubber (HY620# HY640# ) are generally named as two-part room temperature sulfurated silicone rubber, which features an exceptional fluidity and good operability.

When mixed with 2-3% curing agent, they can still be operated within 30 minutes, but will be formed after 2-3 hours.

With resistance to deformation, high temperature, acid and alkali, and expansion, silicon flexible molds are used for mold duplication and delicate mold making for poli crafts, resin crafts lighting and candle crafts.

[4]Frequently asked questions of pouring silicone rubber (HY620# HY640# )

Why does the mold made of silicone rubber have an unsmooth surface with tracks and strips on it? It is due to product or model to be molded should hasn't been sanded or polished . If the mold or product is not sanded or polished, the mold made of whatever quality silicone rubber will not be good and smooth enough since the mold or the product itself is not smooth or perfect. Another case is that uneven brushing of the release agent will also bring about unsmoothness of the mold.

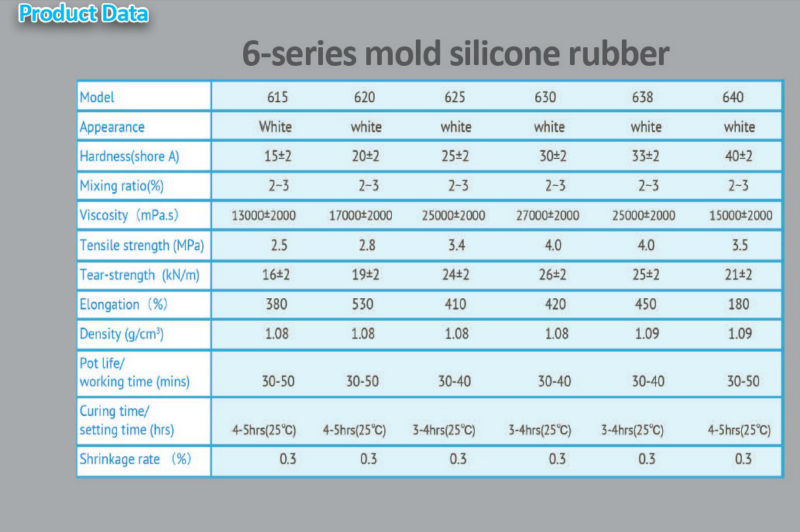

5 Datasheet of the pouring silicone rubber for your reference:

Any questions,please feel free to contact Caroline: Tel: +86-755-89948019 Mobile: +86-18938867567 Skype: cathy19900719 Email: hysf(at)szrl(dot)net Website : www(dot)szrl(dot)net |

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents