PVC/UPVC/WPC wood plastic composite window and door frame profile making machine

- US $43000.00

1 - 3 piece

- US $40000.00

4 - 10 piece

- US $38000.00

11 - 20 piece

group nameWood Plastic Composite WPC machines

-

Min Order1 piece

brand nameQingdao Tongsan

modelSJMS65/132

payment methodL/C, Western Union, MoneyGram, T/T, Paypal

-

update timeWed, 11 Nov 2020 13:12:42 GMT

Paramtents

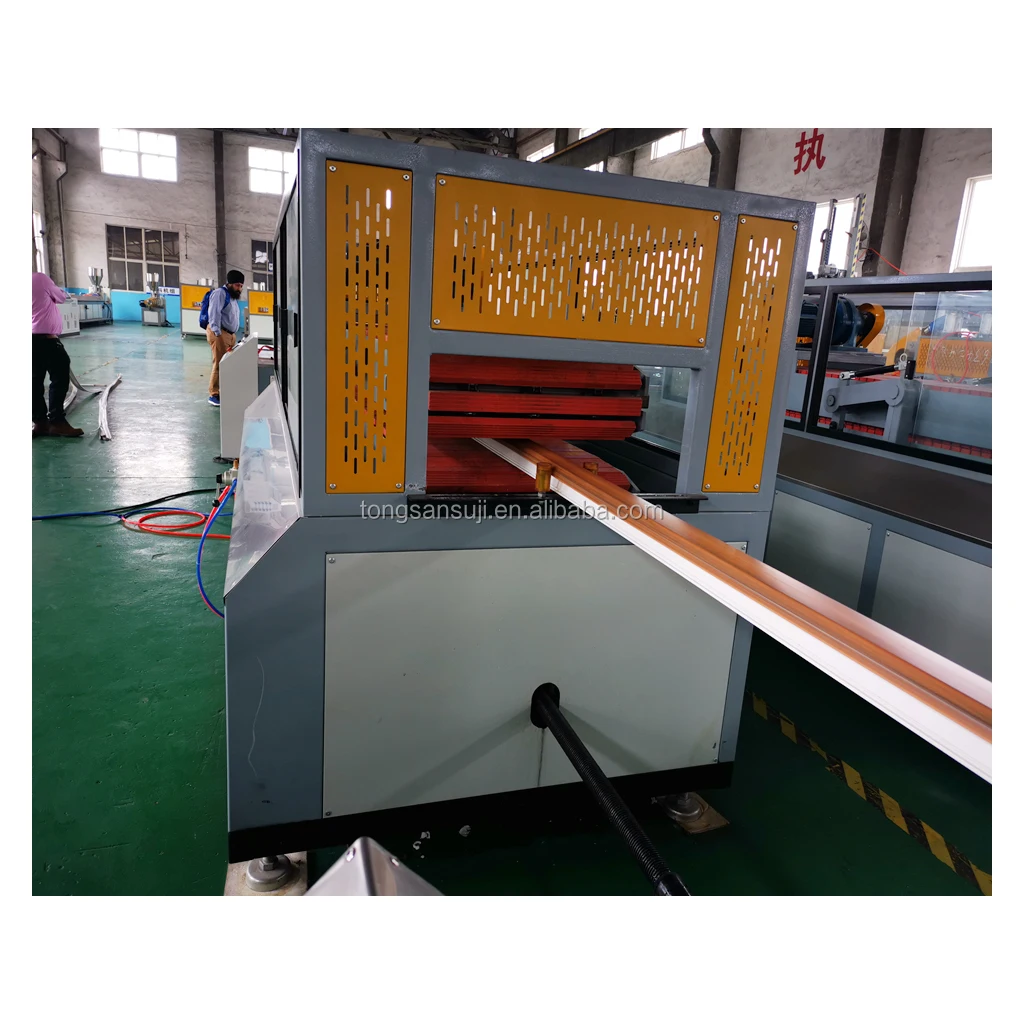

Extruder type Conical double screw extruder

Extruder model SJMS65/132

Capacity 120-240kg/h

Raw material Waste plastic +wood powder+attitives

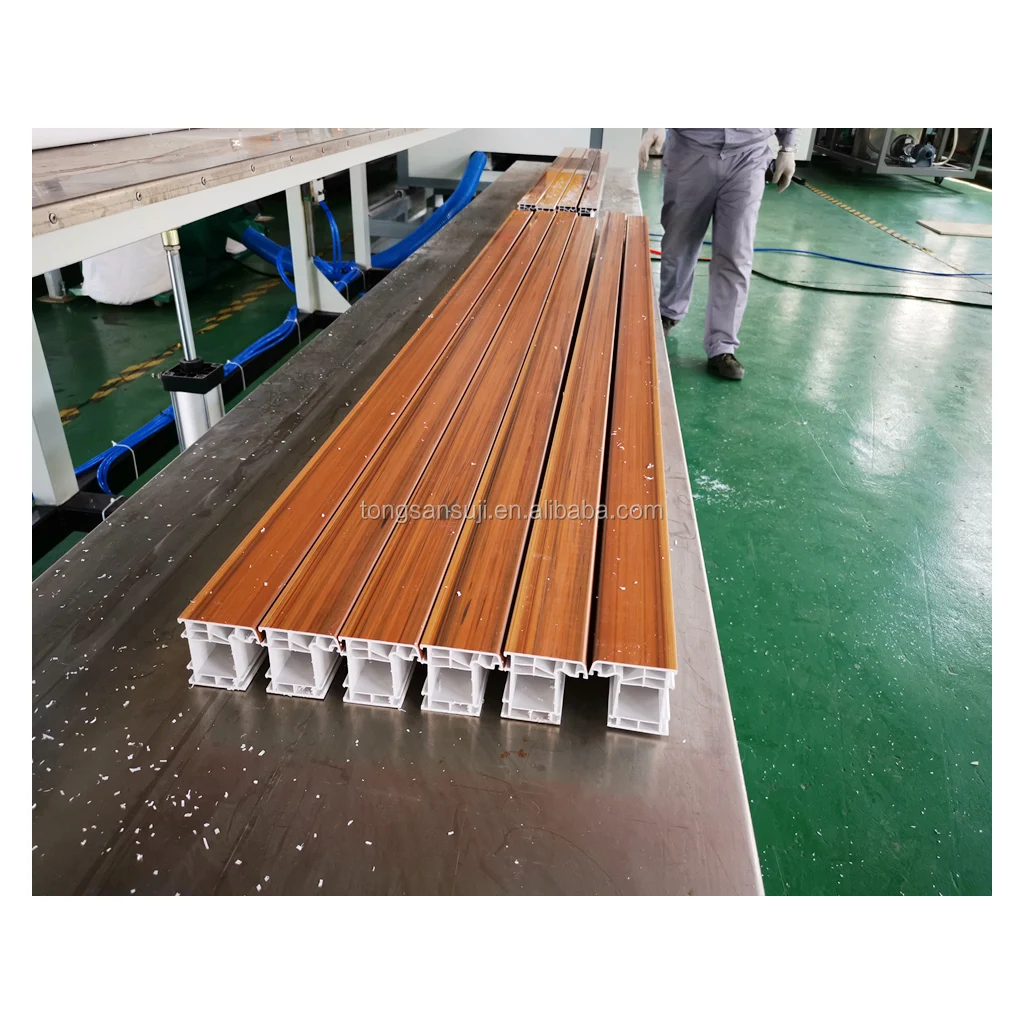

Door frame width 100-300mm

Main motor power 37kw

Inventer ABB

Temperature Controller OMRON

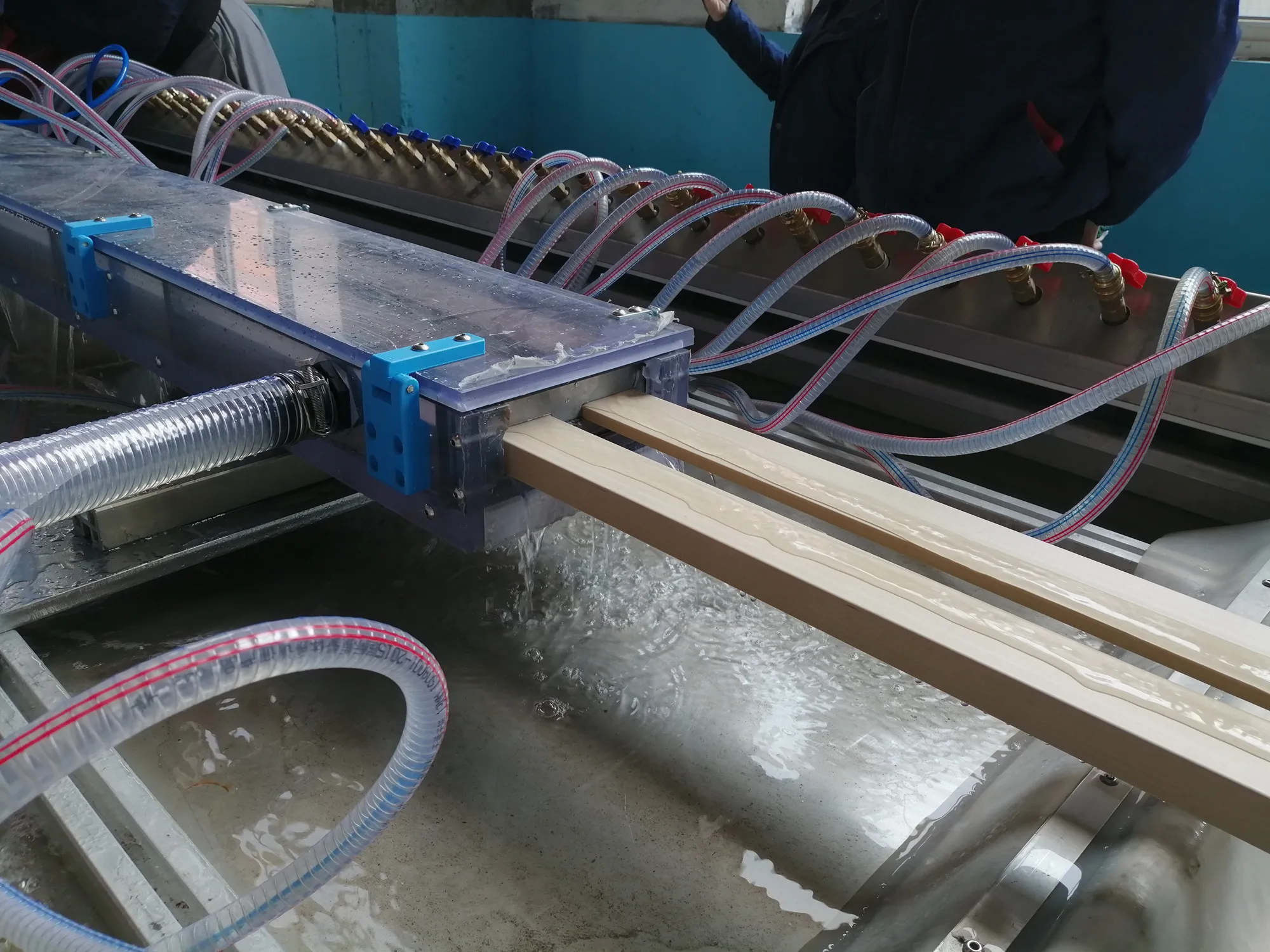

Surface treatment Laminting or painting

Production time 60-90 days

pay terms 30% down payment +70% balance

warranty period 12 months

Packging & Delivery

Min Order1 piece

Briefing

Product: WPC decking, WPC wall cladding, WPC fence, WPC pergola

Detailed

Proper double screw extruder and single screw extruder, specially used for wood plastic products, can be chosen in accordance with the panel section, application, product specific gravity. Also the corresponding auxiliary machines such as vacuum shaping platform, hauling machine, saw machine, material reversing platform, etc. are equipped. Products of diversified specification can be produced with different dies.

Model | Profile Width | Extruder Model | Motor Power | Max.Extrusion Capacity | Calibrating table length |

HG-200 | 200mm | 51/105 | 22kw | 100-120kg/h | 4000mm |

HG-300 | 300mm | 65/132 | 37kw | 150-180kg/h | 6000mm |

HG-400 | 400mm | 65/132 | 37kw | 150-180kg/h | 6000mm |

HG-600 | 600mm | 65/132 | 37kw | 150-180kg/h | 8000mm |

HG-600 | 600mm | 65/132 or 80/156 | 37kw or 55kw | 150-350kg/h | 6000mm |

1.Provide the free consultation of the machine

2.Provide the standard device and the flow chart

3.According to the clients' special requirement, offering the reasonable plan and free design helping to select the machine

4.Welcome to visit our factory or the domestic clients' factory.

Services during the sales

1.Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2.Inspect the machine before leaving the factory.

3.Send our experienced workers and engineer to your factory for installing and adjusting all the machine

4.Train the first-line operator.

5.Provide the basic formula

After sale services

1.One year warranty

2.24 hours online service

3.Engineers available to service machinery overseas

4.Provide technical exchanging

Model | Profile Width | Extruder Model | Motor Power | Max.Extrusion Capacity | Calibrating table length |

HG-200 | 200mm | 51/105 | 22kw | 100-120kg/h | 4000mm |

HG-300 | 300mm | 65/132 | 37kw | 150-180kg/h | 6000mm |

HG-400 | 400mm | 65/132 | 37kw | 150-180kg/h | 6000mm |

HG-600 | 600mm | 65/132 | 37kw | 150-180kg/h | 8000mm |

HG-600 | 600mm | 65/132 or 80/156 | 37kw or 55kw | 150-350kg/h | 6000mm |

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow