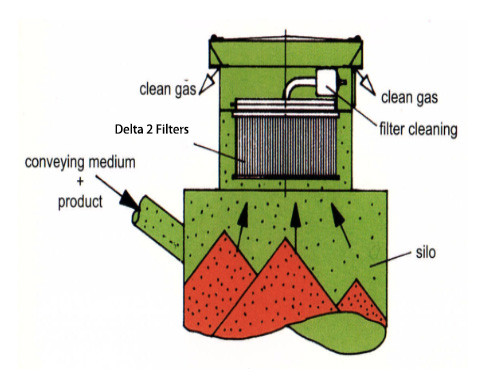

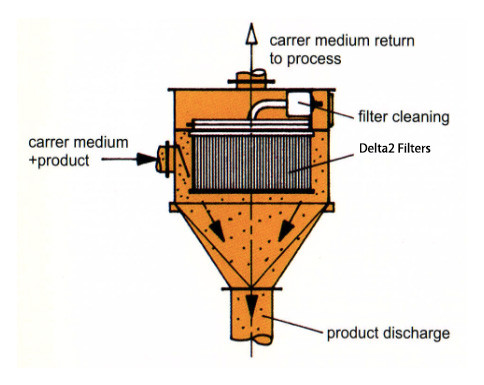

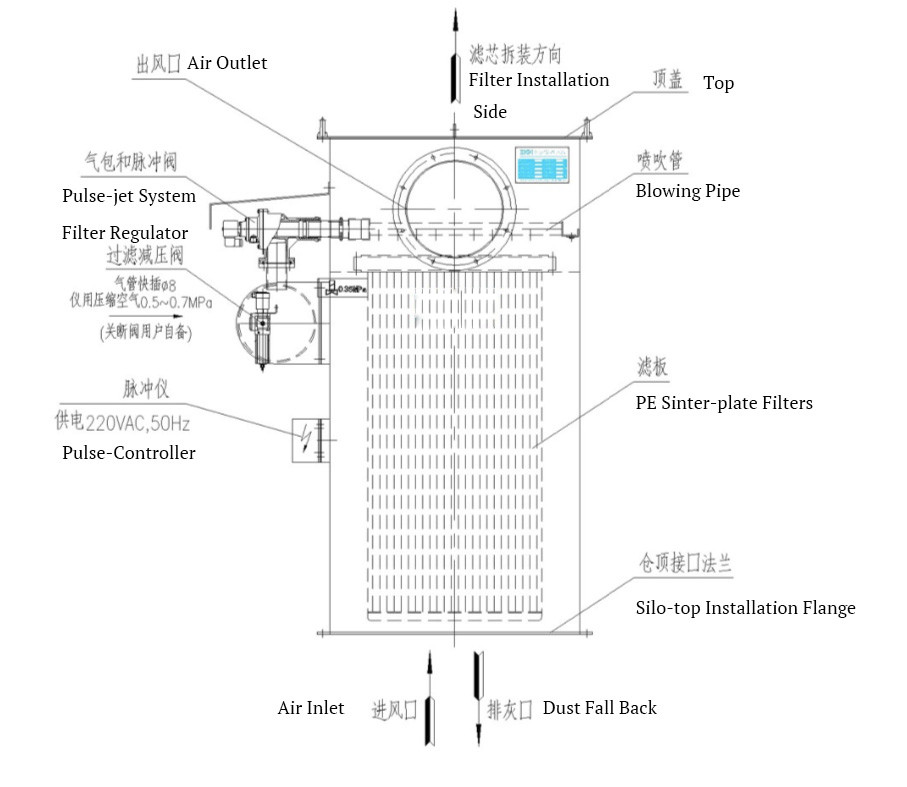

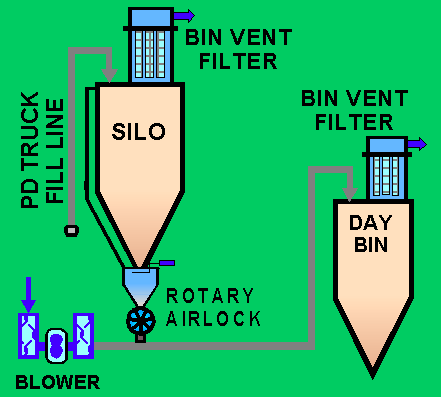

Round Silo Bin Vent Filter, Silo Bin Vent Dust Collector, Silo Top Dust Collector-Silotop Filter

group nameSilo Bin Vent Dust Collector

-

Min Order1 set

brand nameACMAN

modelsilotop filter

payment methodT/T

-

update timeMon, 20 Mar 2023 11:11:42 GMT

Packging & Delivery

Min Order1 set

Briefing

Detailed

|

Model

|

Airflow

|

Outlet Size

|

Connect Size

|

Filter Area | Weight |

m3/h | mm | mm | m2 | kg | |

VO-BA2 | 188 | 110 | 3.14 | 70 | |

VO-BB2 | 280 | 110 | 4.68 | 80 | |

VO-BA3 | 280 | 110 | 650*460 | 4.71 | 90 |

VO-BB3 | 420 | 160 | 7.02 | 100 | |

VO-BC3 | 570 | 160 | 9.54 | 110 | |

VO-BB4 | 560 | 160 | 9.36 | 135 | |

VO-BC4 | 765 | 160 | 12.72 | 150 | |

VO-BB6 | 840 | 160 | 700*600 | 14.04 | 180 |

VO-BC6 | 1150 | 220 | 19.08 | 200 | |

VO-BD6 | 1710 | 275 | 28.5 | 250 | |

VO-BB8 | 1120 | 220 | 700*750 | 18.72 | 220 |

VO-BC8 | 1530 | 220 | 25.44 | 250 | |

VO-BD8 | 2280 | 275 | 38 | 300 | |

|

VO-BB10

|

1400

|

220

|

700*950 |

23.4 | 260 |

|

VO-BC10

|

1900

|

275

|

31.8 | 300 | |

|

VO-BD10

|

2850

|

330

|

47.5 | 350 |

You need a product

You May Like

6YRS ACMAN ENVIRONMENT CO., LTD

- Nearest port for product export

- Ningbo, Shanghai

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow