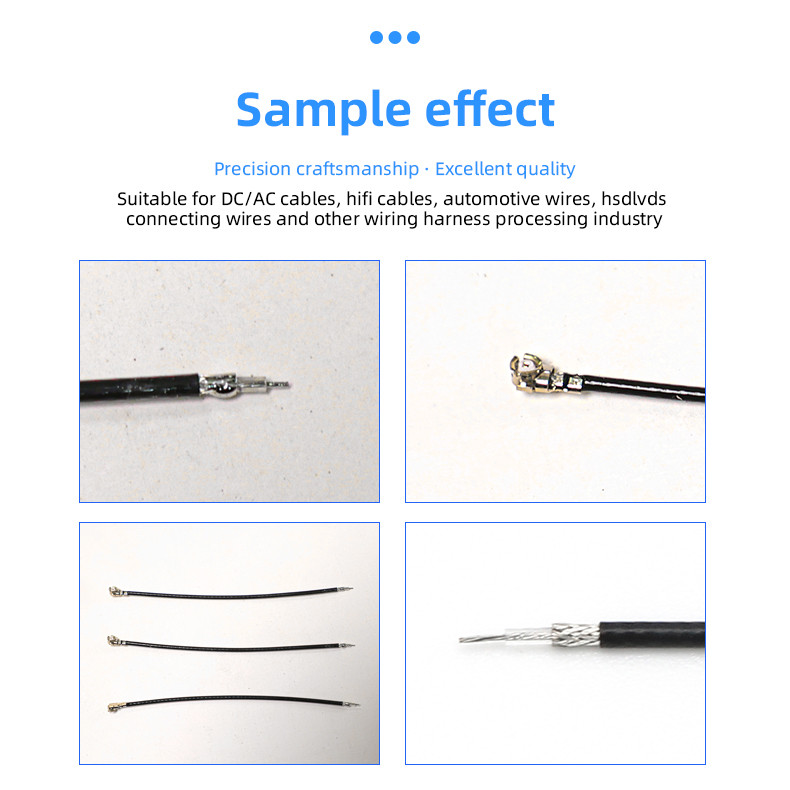

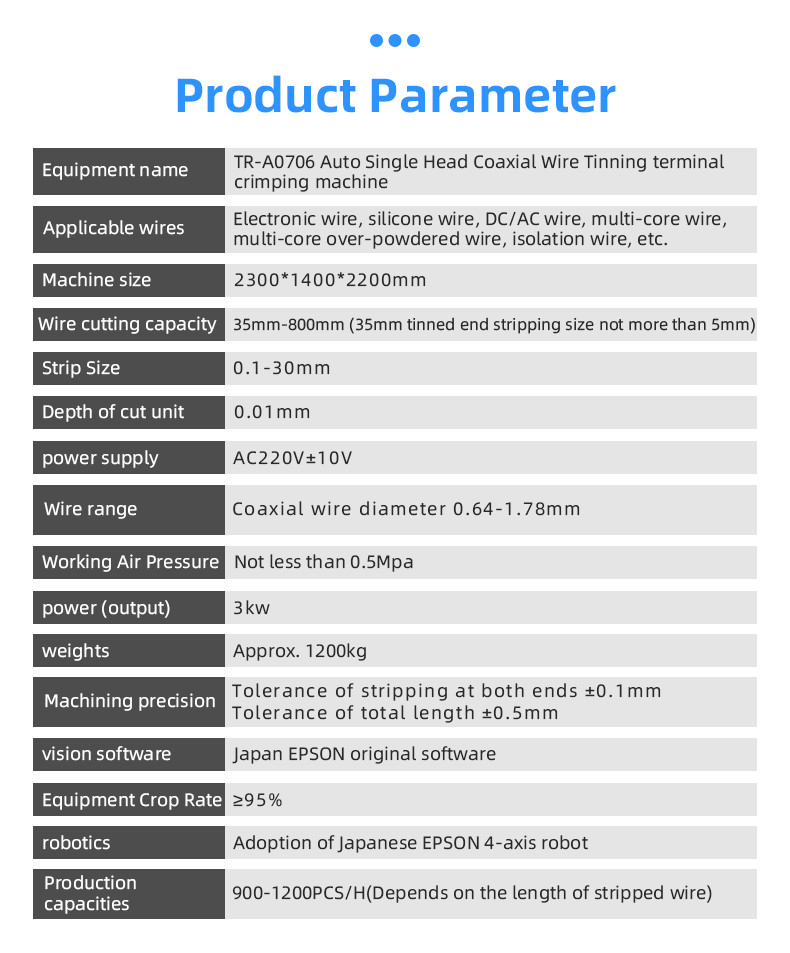

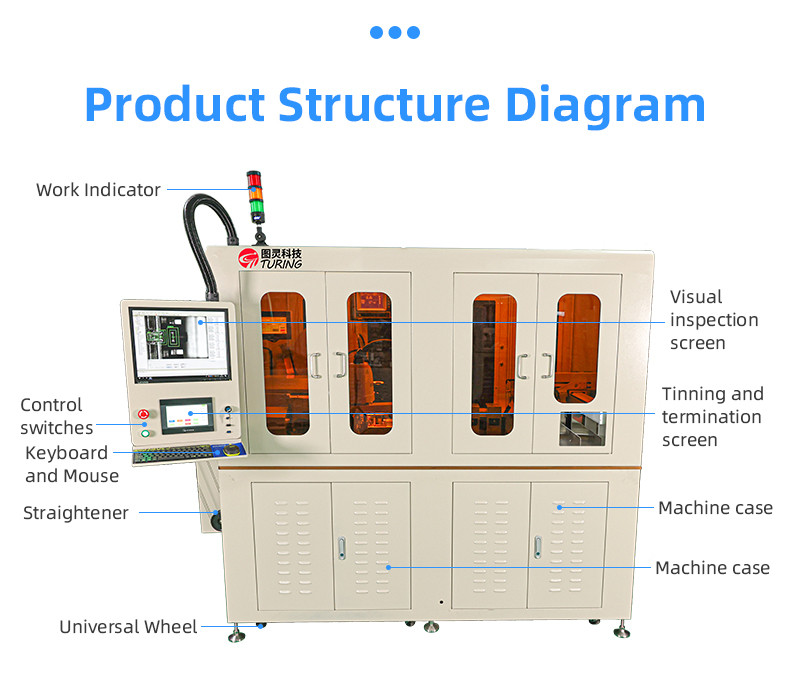

TR-A0706 Single-head coaxial wire tin terminal Crimping machine

group nameDipping Tin Terminal Crimping Machine

-

Min Order1 piece

brand nameTuring

modelTR-A0706

payment methodWestern Union, MoneyGram, T/T

-

update timeFri, 01 Nov 2024 07:11:08 GMT

Paramtents

Power AC220V/50HZ, 300W

Application Single-head coaxial wire tin terminal machine

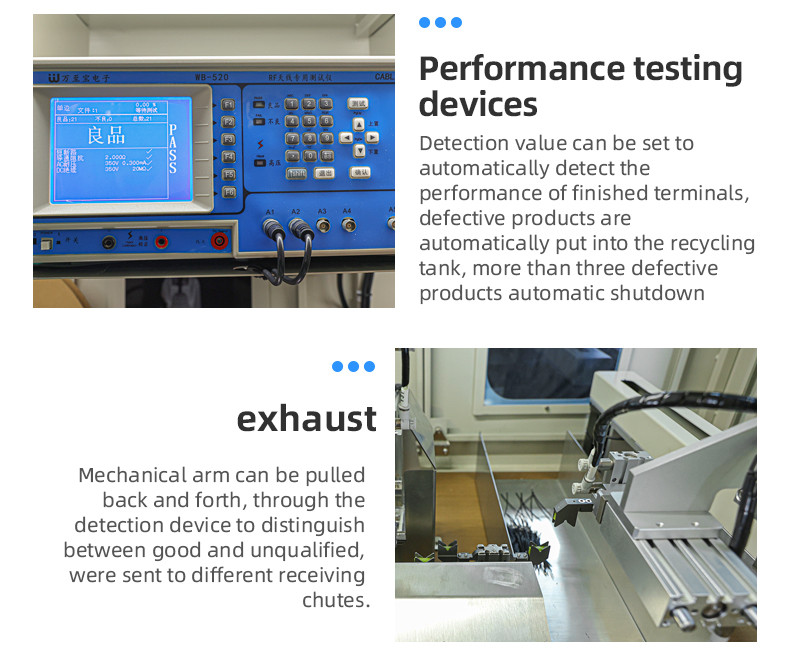

Feature Stable Performance

Warranty 1year

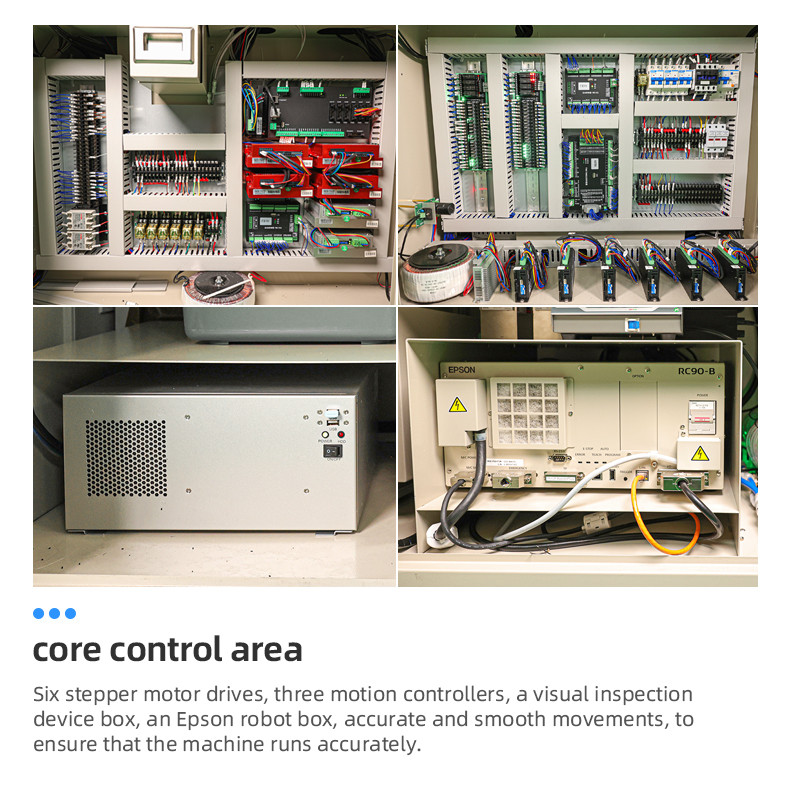

Control Servo and Step motor

Contact Lily 0086-13715588365

Packging & Delivery

Size180cm x 120cm x 150cm

Min Order1 piece

Briefing

Lily +8613715588365

Detailed

You need a product

You May Like

- Nearest port for product export

- Yantian, Huangpu, Shekou, Nansha

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, MoneyGram, Westem Union, Cash