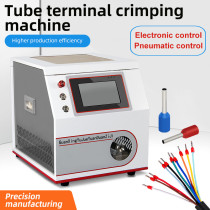

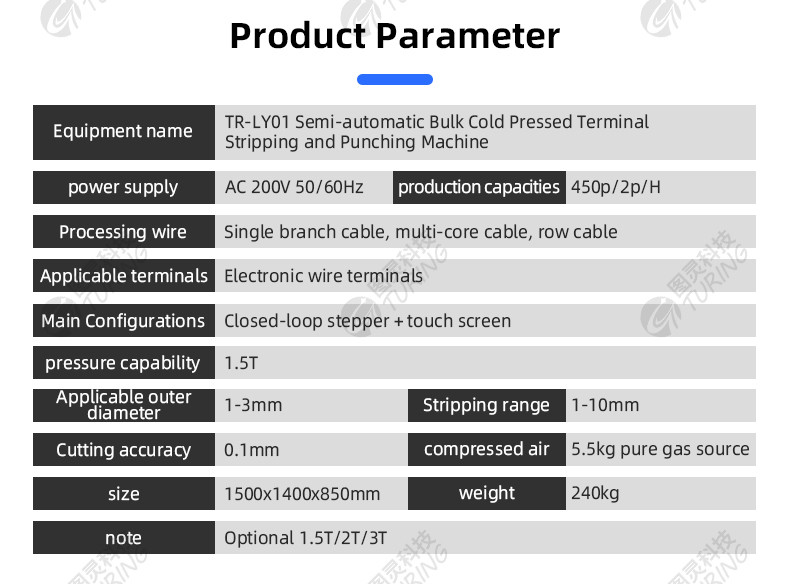

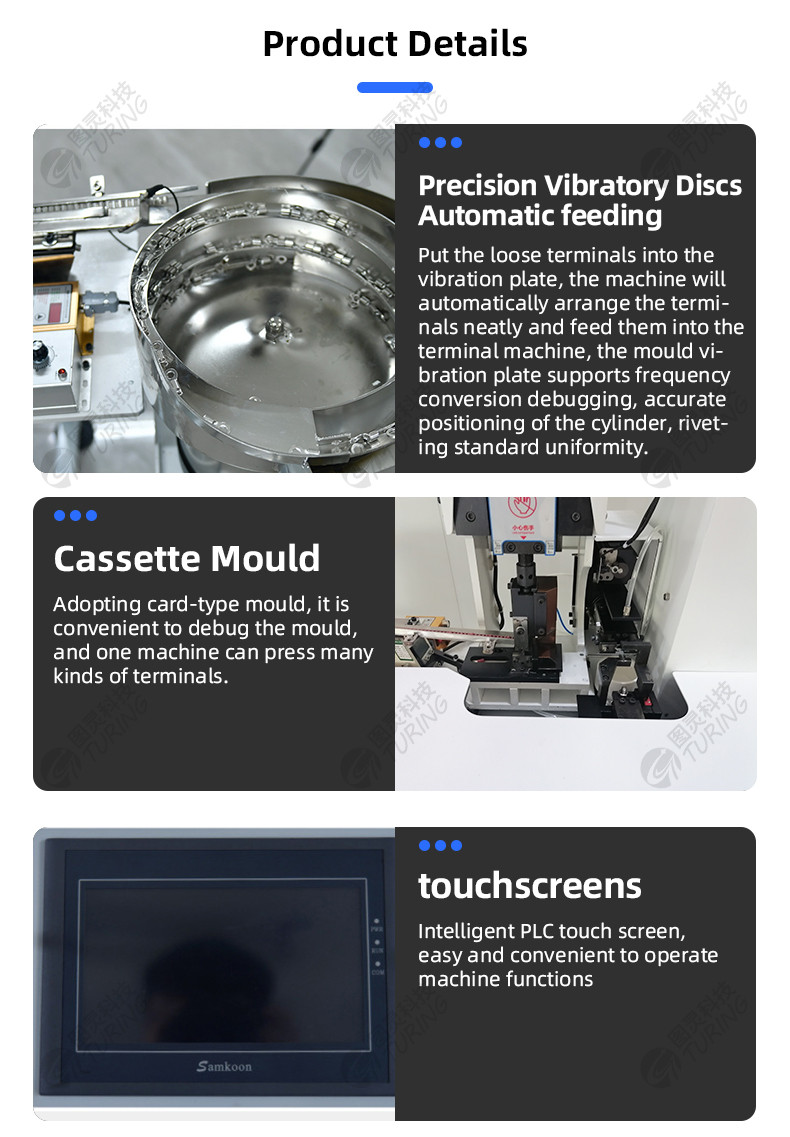

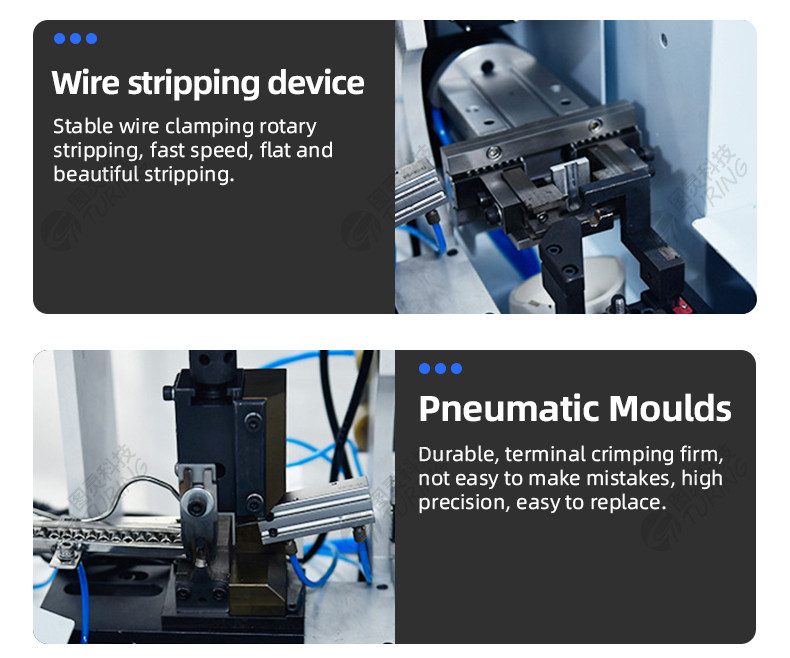

TR-LY01 semi-automatic bulk cold-pressed terminal stripping and crimping machine

group nameSemi-automatic Bulk Terminal Crimping Machine

-

Min Order1 piece

brand nameTuring

modelTR-LY01

payment methodWestern Union, MoneyGram, T/T

-

update timeFri, 24 May 2024 06:32:01 GMT

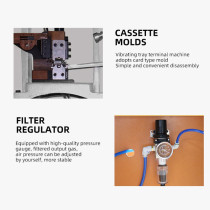

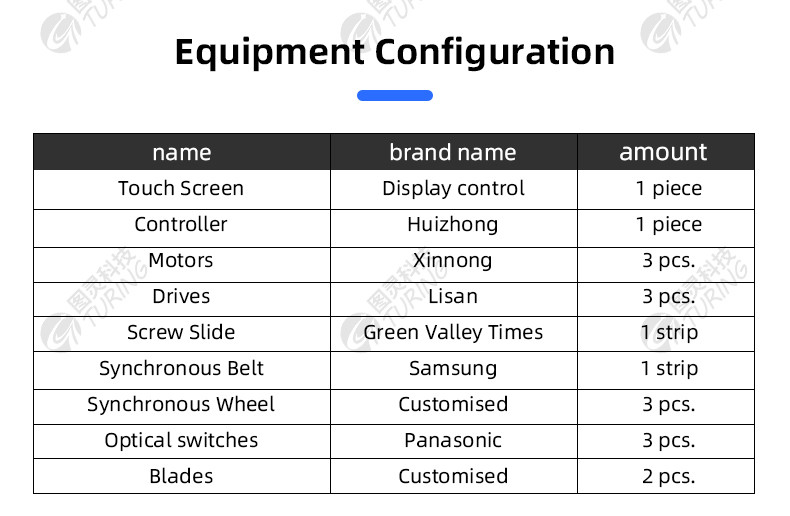

Paramtents

Power AC220V/50HZ,

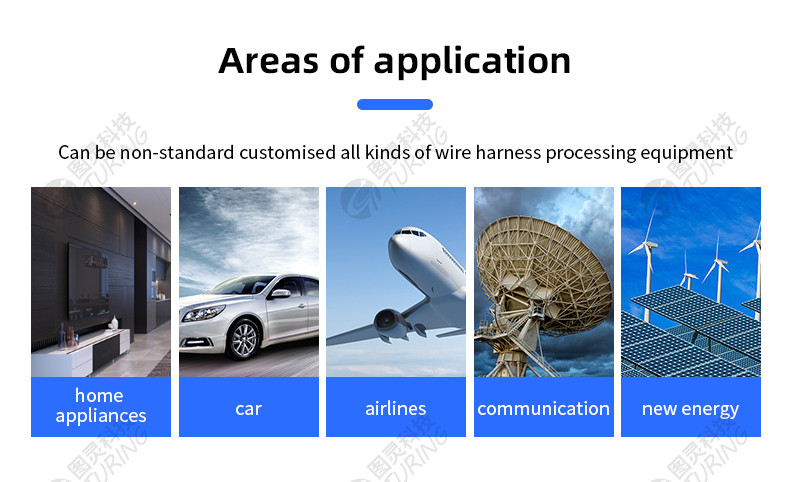

Application Stripping wire and terminal crimping machine

Feature Stable Performance

Warranty 1year

Contact Lily 0086-13715588365

Packging & Delivery

Min Order1 piece

Briefing

Detailed

You need a product

You May Like

- Nearest port for product export

- Yantian, Huangpu, Shekou, Nansha

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, MoneyGram, Westem Union, Cash