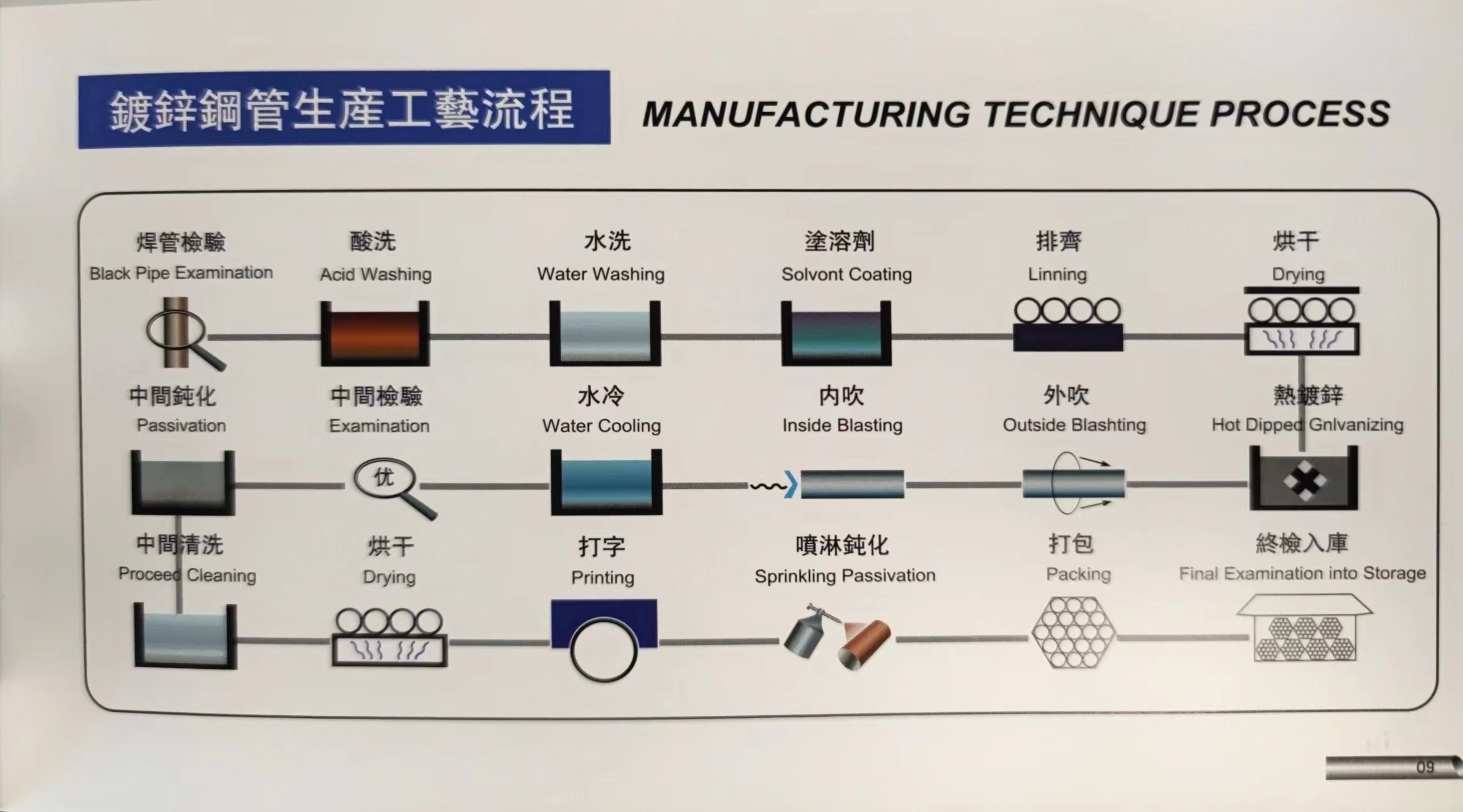

Hot Dipped Galvanized Seamless Steel Pipes Support Customized

group nameCarbon Seamless Pipe

-

Min Order5 metric ton

brand nameBAOLAI Steel Pipe Wholesale Manufacturer

modelASTM A53/ A106/ API 5L/ ISO 65

payment methodT/T, L/C, D/P D/A, Westem Union

-

update timeWed, 07 Dec 2022 16:41:17 GMT

Paramtents

Certification API

Grade Gr.B

Out Diameter 1/2" - 26"

Wall Thickness 1 - 60 mm

Length 6M/ 12M or Customized

Usage Construction

The Thickness of Zinc 200 - 550 g/㎡

Packging & Delivery

Min Order5 metric ton

Briefing

Detailed

- √Uniform Coating

- √Strong Adhesion

- √Strong Corrosion Resistance

- √Long Service Life

NPS Designator | DN Designator | Outside Diameter | Wall Thickness |

mm |

mm |

||

1/2" | 15 | 21.3 | 2.77 |

3.73 | |||

4.78 | |||

7.47 |

|||

6" | 150 | 168.3 | 4.78 |

5.56 | |||

6.35 | |||

7.11 | |||

7.92 | |||

8.74 | |||

9.52 | |||

10.97 |

- √OEM & ODM

- √Protective Coatings

- √Saw and Flame Cutting

- √Threading and Bending

- For more information, please contact our service team.

You need a product

You May Like

- Nearest port for product export

- TIANJIN

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, DDP, DDU

- Acceptable payment methods

- T/T, L/C, D/P D/A, Westem Union