High Speed Centrifuge Turbo Blower Parameter in Water Treatment Plant Application

1. Aeration: High speed turbine fans are used in aeration systems in water treatment processes to help oxidise and remove organic pollutants by delivering oxygen to the water. This plays a vital role in the metabolic activity of microorganisms in biological treatment processes such as biofilters and aeration tanks.

2. Nitrogen and Phosphorus Removal: In biological nitrogen removal and phosphorus removal processes, the oxygen supplied by the high speed turbine fan supports the growth of nitrifying and denitrifying bacteria and promotes the conversion and removal of nitrogen. In addition, the uptake and removal of phosphorus by aerobic microorganisms is facilitated by aeration.

3. Water quality homogenisation: The high speed turbine fan maintains water quality homogeneity at all stages of the water treatment process through stirring and mixing, avoiding dead space and sedimentation, and improving the treatment effect. Uniform water quality contributes to the stable operation of subsequent treatment processes.

4. Enhance treatment efficiency: As the high-rotation turbine fans are characterised by high efficiency and low energy consumption, they are able to provide sufficient air while reducing energy consumption, significantly improving the operating efficiency of the entire water treatment system and reducing operating costs.

5. Support oxidation process: In some special treatment processes, such as ferromanganese oxidation and organic matter oxidation, the sufficient oxygen provided by the high speed turbine fan can accelerate these oxidation reactions, ensure the effective removal of harmful substances and improve the quality of water.

6. Reduce sludge production: Efficient aeration and mixing can promote the complete degradation of organic matter, thus reducing the amount of sludge produced. This not only reduces the cost of sludge treatment and disposal, but also reduces the risk of secondary pollution.

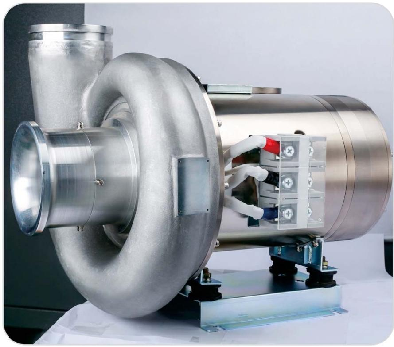

7. Reliability and Maintenance: High-speed turbine fans are advanced in design, compact in structure, stable in operation and simple in maintenance. They are able to maintain good performance under prolonged high load operating conditions, ensuring continuous and stable operation of the water treatment plant.

8. Reduced noise pollution: Compared with traditional fans, high speed turbine fans have lower noise levels, which improves the working environment, reduces the noise impact on the neighbourhood, and meets environmental and occupational safety and health requirements.