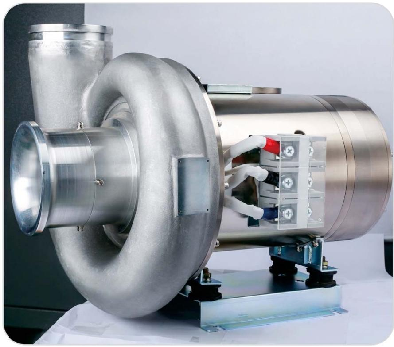

High Pressure Energy Saving Air Suspension Centrifugal Blower Air Blower Industrial Blower Turbo for Power Plants

group nameHigh Speed Turbo Blower

-

Min Order1 set

brand nameAquaSust Wastewater Treatment Solutions

modelAS-CZA

payment methodL/C, D/A, D/P

-

update timeWed, 05 Jun 2024 18:32:28 GMT

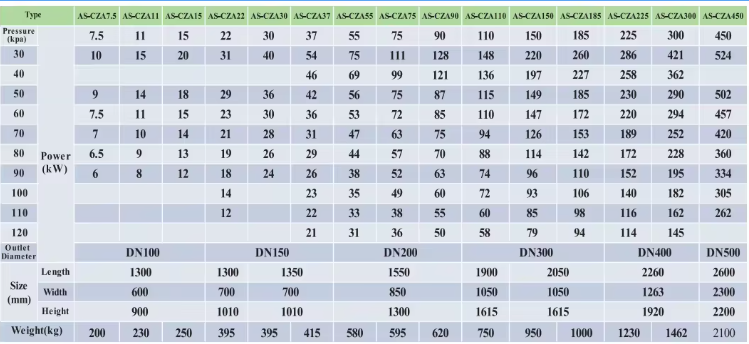

Paramtents

After-sales service Support

Guarantee period 3 Years

Shipment packing Custom

Brand AquaSust

Rated Voltage 220V

Power Source Electric Blower

Color Customized Color

Packging & Delivery

Min Order1 set

Briefing

Detailed

You need a product

You May Like

- Nearest port for product export

- shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A