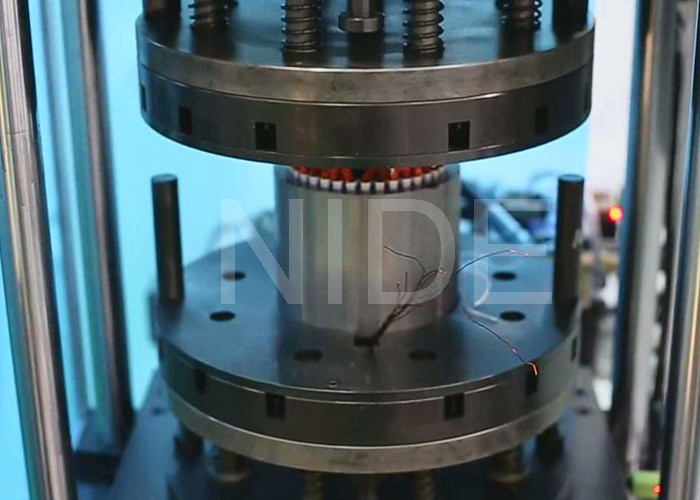

Automatic Enter and Exit Station Stator Winding Final Forming Machine

group nameFinal forming machine

-

Min Order1 piece

brand nameNIDE

modelZ3XL1-150/160

payment methodL/C, T/T

-

update timeSun, 09 Oct 2016 15:24:11 GMT

Packging & Delivery

Size65cm x 90cm x 230cm

Weight700kg / piece

Min Order1 piece

Briefing

Detailed

This forming machine has a wide range and easy to operate. The stator coils will be automaticly formed or shaped by machine tooling. The inner coils will be expanded, while the outside coils will be wrapped. This machine is consist of machine framework, oil hydraulic power system, control system, and forming tooling system.

Technical parameter:

Stator O.D | less than 160mm |

Stator I.D | 30~110mm |

Stack height | 20~150mm |

Displacement of cylinder | 20L |

Power supply | 1500 W |

Voltage | 380V/50/60Hz |

Weight | 700KG |

Dimension | L850*W1000*H2300mm |

Stator coil forming machine

Machine main function and characteristic

1. This machine adopts whole hydraulic system and PCL program.

2. This machine can adjust the forming stack length by changing washer.

3. Both slot paper and wedge should not be damaged or turned over. The stator should not be deformation or stator lamination should not be upward. There is no wire enamel broken.

4. Production capacity ≤13s/set (exclude loading/unloading time)

5. Primary qualification rate ≥99.5%, after rework, the rate ≥99.9%

6. This machine adopts safety grating protection system. Operator need to stand when operating.

7. Machine adopts two hands simultaneously start button to ensure safety.

8. Primary qualification rate ≥98.5%, after rework, the rate ≥99.5%

9. His machine adopts safety grating protection system. Operator need to stand when operating.

l0.Machine adopts two hands simultaneously start button to ensure safety.

Machine operation steps

1. After connected to the power source and air source, switch the button to on. Press hydraulic start button; switch to auto mode.

3. Press "reset" button. Check if all parts are in the correct position.

4. Put stator into the groove. Press "Start" button by two hands. Machine will auto form.

Note: there are two triangle blocks (diagonal line) in the groove. The two holes on the stator should be aligned to the two triangle blocks separately. And make sure the wire should be put together as below picture.

You need a product

You May Like

- Nearest port for product export

- SHANGHAI, NINGBO

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C

- Export mode

- Have the independent export and import right